Bend-twist coupling type piezoelectric driving track traveling device and working method thereof

A piezoelectric driving and driving device technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Low speed, slow movement speed and other problems, to achieve the effect of flexible and changeable structure, high electromechanical coupling efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

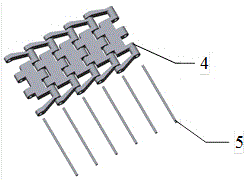

[0024] The bending-torsion coupling type piezoelectric driving crawler traveling device provided by the present invention includes a metal crawler 1 , two ring members 2 and a variable-section piezoelectric transducer 3 . The variable-section piezoelectric transducer 3 includes a variable-section beam 3-1, two pre-tightening wedge devices 3-2, a first torsional vibration piezoelectric ceramic sheet 3-3, an input electrode sheet 3-4, a second torsional vibration Piezoelectric ceramic sheet 3-5, ground electrode sheet 3-6, first bending vibration piezoelectric ceramic sheet 3-7, second bending vibration piezoelectric ceramic sheet 3-8, third torsional vibration piezoelectric ceramic sheet 3-9 , the fourth torsional vibration piezoelectric ceramic sheet 3-10, the third bending vibration piezoelectric ceramic sheet 3-11, and the fourth bending vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com