Drum Type Pneumatic Subsoiler

A subsoiler and drum-type technology, which is applied in the field of drum-type pneumatic subsoiling machinery, can solve the problems of large tillage specific resistance, small loosening range, and large energy consumption, so as to facilitate deep plowing, deepen the depth of subsoiling, increase The effect on food production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

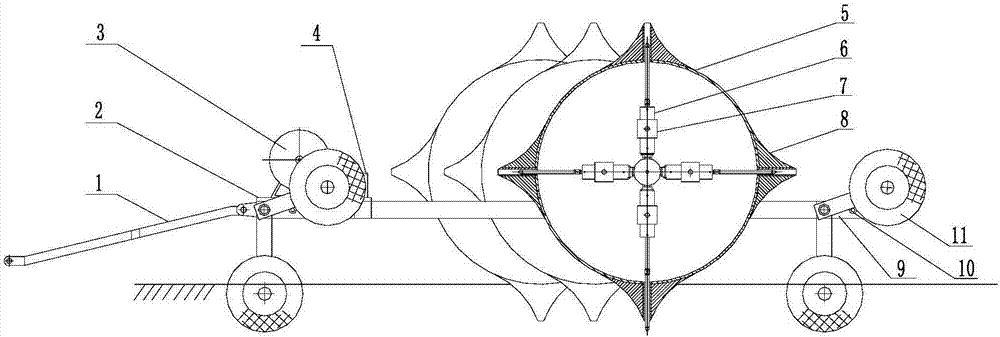

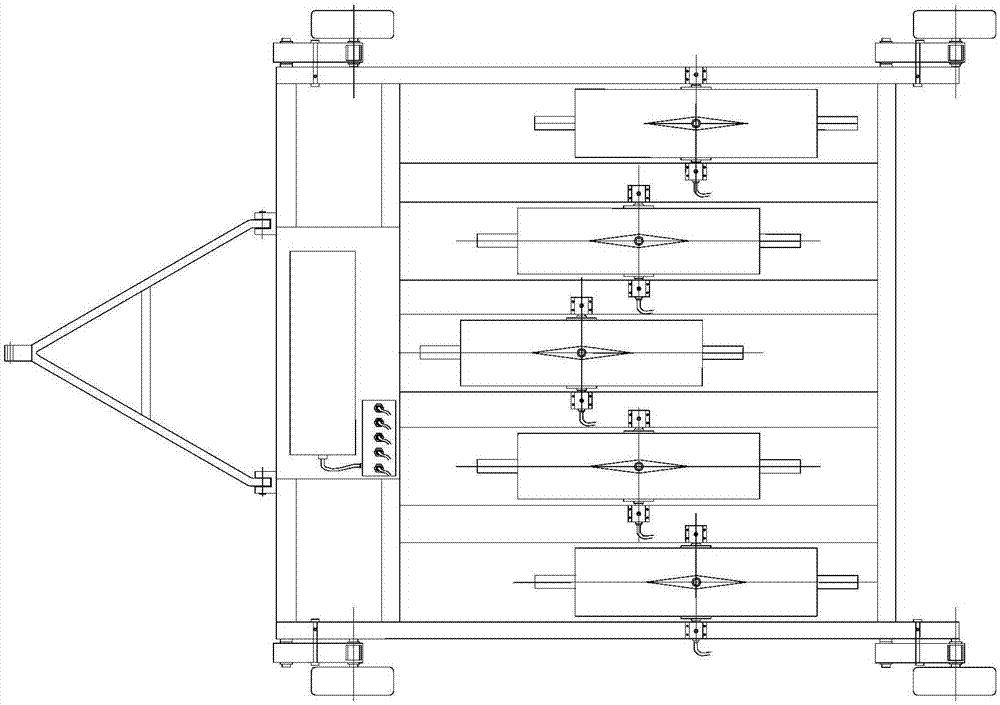

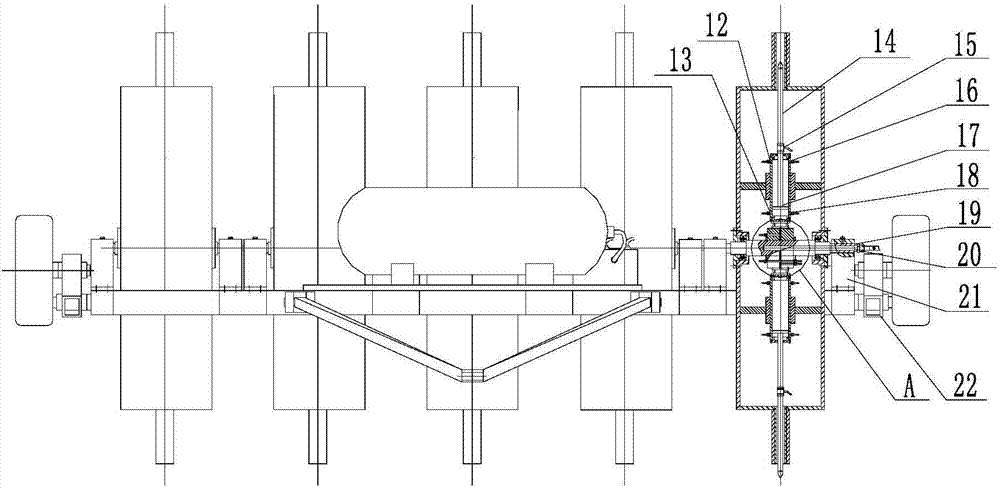

[0022] A drum type air pressure subsoiler, its main components include: frame 9, high pressure gas storage tank 3, drum 5, gas transmission shaft 19, air hole converter 24, cylinder 6, subsoiling air gun 14, air gun guide 8 1. Frame support device, the described drum type air pressure subsoiler is characterized in that the fixed traction frame 1 at the front end of the frame 9 is hinged with the traction ring at the rear of the tractor, and the two sides are connected with the support wheel 11 through the support wheel bracket 22, and the front part Fix a support plate 2 of the gas storage tank, and fix the high-pressure gas storage tank 3 on the support plate 2 of the gas storage tank. Two output ports communicate with the high-pressure gas input port 20 arranged at one end of the gas transmission shaft 19 at the center of the drum 5 through the high-pressure air pipe respectively, and the gas transmission shaft 19 is equipped with a vent hole converter 24 at its two ends with...

Embodiment 2

[0026] The gas transmission shaft 19 is provided with an axial vent hole and a radial vent hole. The axial vent hole is opened from one end of the high-pressure gas input port along its axis to the place where it communicates with the radial vent hole. The radial vent hole Open from the circumferential surface to the center of the shaft and communicate with the axial vent hole, install it on the side close to the ground, make the axial direction of the radial vent hole tilt forward by an angle of β relative to the plane passing through the axis of the gas transmission shaft 19 and perpendicular to the ground, The β angle is determined by the calculation of the cylinder 5 diameter, the forward speed of the complete machine and the 14 moving speeds of the subsoiling air gun. During work, the high-pressure gas is transmitted to the axial ventilation hole of the gas transmission shaft 19 through the flexible pipe, and then transmitted to the radial ventilation hole of the gas trans...

Embodiment 3

[0028] When the drum type air pressure subsoiler is working, the support wheel 11 is lifted, the drum 5 falls to the ground, the tractor pulls the frame 9 to move, and the manual shut-off valve 28 is opened to make the high pressure in the high pressure gas storage tank 3 fixed on the frame 9 The gas is delivered to the gas control box 4 through the high-pressure air pipe, and the 5 output ports of the gas control box 4 transmit the high-pressure gas to the respective gas transmission shafts 19 of the 5 drums 5, and the 4 deep loosening air guns 14 in the drum 5, along with Drum 5 does circular motion, when drum 5 turns to attached Image 6 In the middle (a) position, the radial air hole of the gas transmission shaft 19 communicates with the air gun press-in stroke air supply port 23 of the air gun converter 24, and the air gun press-in stroke air supply port 23 transmits high-pressure gas to the air gun through the high-pressure air pipe Press into the stroke air inlet 13, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com