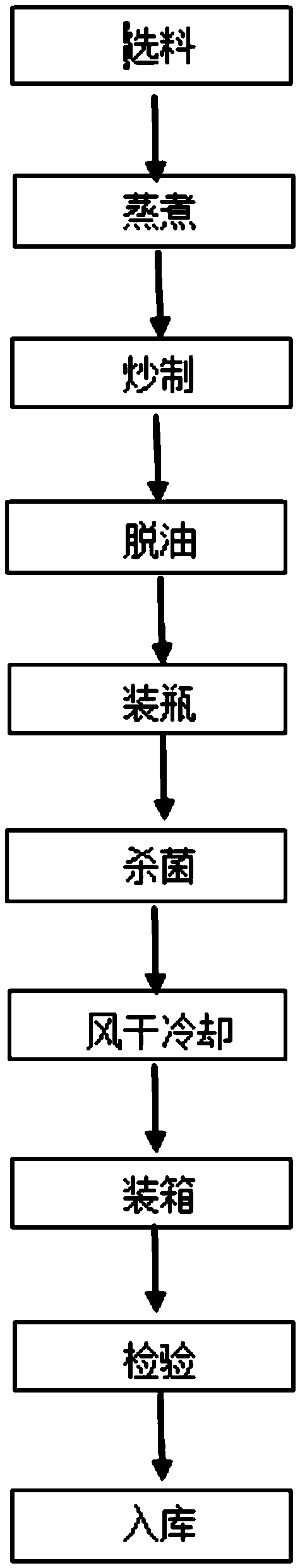

Process for producing bottled black garlic beef paste

A production process and beef sauce technology, applied in the field of food processing, can solve the problems of heavy taste, low export volume, greasy taste impact, etc., and achieve the effect of delicate and soft taste, high export rate and pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Material selection

[0030] Material selection method: choose fresh Shandong Southwest Yellow Beef for beef, remove the fat and tendon skin, cut into meat pieces of uniform size with a meat cutter, clean them, and set aside; choose black garlic that has just come out of the oven after fermentation, and observe the garlic skin , remove the problematic black garlic, select qualified black garlic, remove the garlic skin and clean the garlic grains, and set aside;

[0031] 2. Cooking

[0032] The method of steaming beef: put the bones after removing the beef at the bottom of the pot, put the above-mentioned cleaned beef tender meat in the middle, and put the old meat around, add boiling water, add ingredients: all ingredients bag, dark soy sauce, cooking wine, ginger, Scallions and garlic, steamed over high heat, remove the beef after 35 minutes, quickly cool down to 10°C-18°C with cold boiled water, and set aside; filter the old soup in the pot after cooking, remove im...

Embodiment 2

[0047] 1. Material selection

[0048] Material selection method is the same as embodiment 1

[0049] 2. Cooking

[0050] The method of steaming beef: put the bones after removing the beef at the bottom of the pot, put the above-mentioned cleaned beef tender meat in the middle, and put the old meat around, add boiling water, add ingredients: all ingredients bag, dark soy sauce, cooking wine, ginger, Scallions and garlic, steamed over high heat, remove the beef after 38 minutes, quickly cool down to 10°C-18°C with cold boiled water, and set aside; filter the old soup in the pot after cooking, remove impurities, pour it into a container, set aside;

[0051] The weight ratio of the ingredients in the cooking process is as follows: for every 100 kg of beef cooked, 0.3 kg of Chinese prickly ash, 0.3 kg of star anise, 0.3 kg of cinnamon bark, 0.4 kg of bay leaves, 0.3 kg of cumin, 0.9 kg of hawthorn, and 0.2 kg of cloves kg, 1.1kg of galangal, put in the pocket after mixing and secur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com