Crude terephthalic acid hydrofining catalyst

A crude terephthalic acid, hydrorefining technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, carboxylate preparations, etc., can solve problems such as catalyst poisoning, and improve the Anti-toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

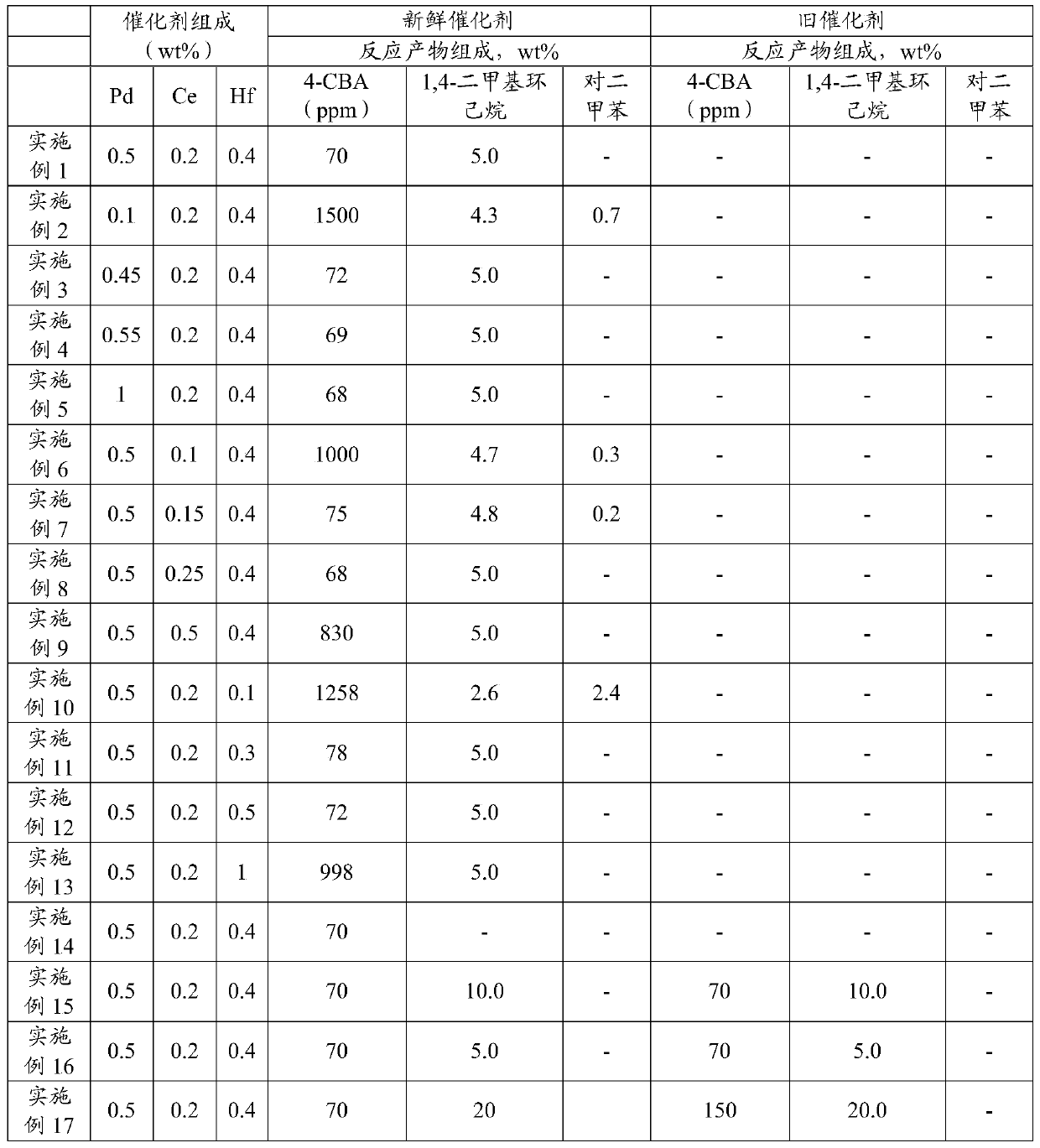

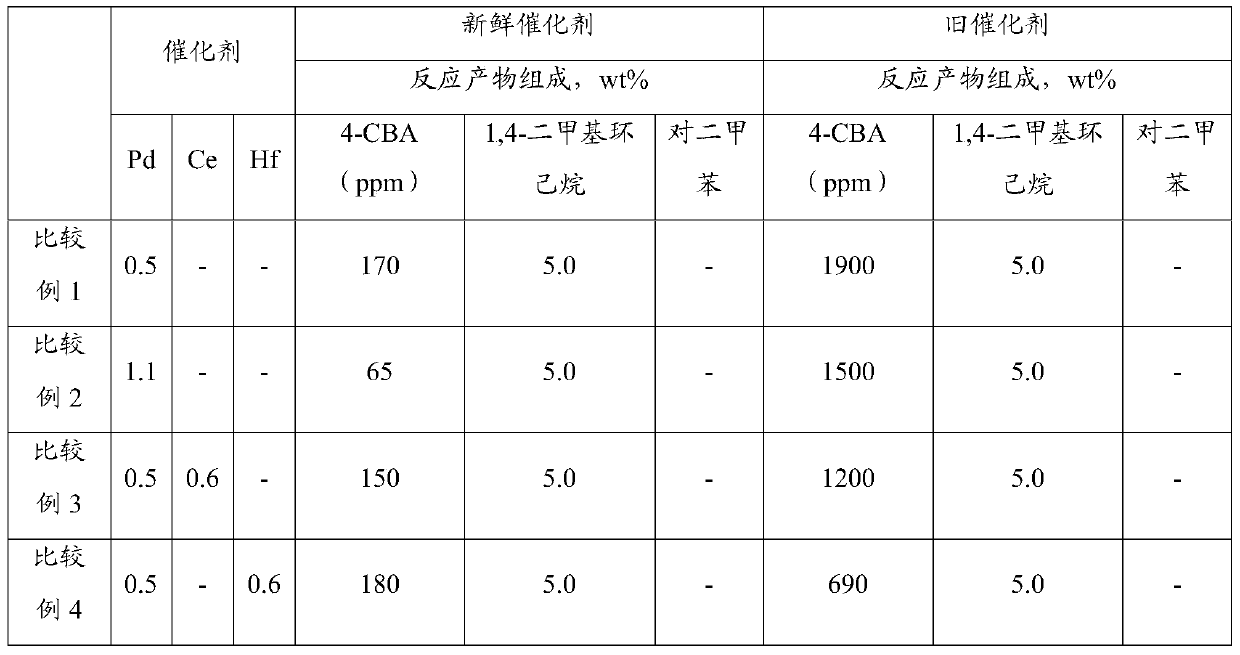

[0019] The preparation of catalyst: first according to the Pd content in Pd-Ce-Hf / C catalyst is 0.5wt%, Ce content is 0.2wt% and Hf content is 0.4wt% and weighs the corresponding mass of H 2 PdCl 4 , CeCl 3 and HfCl 4 And dissolve it in 15wt% hydrochloric acid to form 250ml impregnation solution, mix the resulting impregnation solution with 50 grams of activated carbon, impregnate for 12h, then vacuum dry at 110°C for 3h to obtain a catalyst precursor, and finally use 5 times the volume of nitrogen diluted hydrogen Reduction at 160°C for 3 hours at 150ml / min and filtration to obtain the finished Pd-Ce-Hf / C catalyst. According to ICP-AES analysis, the Pd content in the catalyst is 0.5wt%, the Ce content is 0.2wt%, and the Hf content is 0.4wt%. , for the convenience of comparison, the resulting catalyst composition is listed in Table 1.

[0020] Catalyst evaluation: 18g of crude terephthalic acid containing 3300ppm p-carboxybenzaldehyde (4-CBA), 5wt% PX, 42g of water and 2g o...

Embodiment 2

[0022] The preparation of catalyst: first according to the Pd content in Pd-Ce-Hf / C catalyst is 0.1wt%, Ce content is 0.2wt% and Hf content is 0.4wt% and weighs the corresponding mass of H 2 PdCl 4 , CeCl 3 and HfCl 4 And dissolve it in 15wt% hydrochloric acid to form 250ml impregnation solution, mix the resulting impregnation solution with 50 grams of activated carbon, impregnate for 12h, then vacuum dry at 110°C for 3h to obtain a catalyst precursor, and finally use 5 times the volume of nitrogen diluted hydrogen Reduction at 150ml / min at 160°C for 3h and filtration to obtain the finished Pd-Ce-Hf / C catalyst. According to ICP-AES analysis, the Pd content in the catalyst is 0.1wt%, the Ce content is 0.2wt% and the Hf content is 0.4wt%. , for the convenience of comparison, the resulting catalyst composition is listed in Table 1.

[0023] Catalyst evaluation: 18g of crude terephthalic acid containing 3300ppm p-carboxybenzaldehyde (4-CBA), 5wt% PX, 42g of water and 2g of the ...

Embodiment 3

[0025] The preparation of catalyst: first according to Pd-Ce-Hf / C catalyst, Pd content is 0.45wt%, Ce content is 0.2wt% and Hf content is 0.4wt% and weighs the H of corresponding mass 2 PdCl 4 , CeCl 3 and HfCl 4 And dissolve it in 15wt% hydrochloric acid to form 250ml impregnation solution, mix the resulting impregnation solution with 50 grams of activated carbon, impregnate for 12h, then vacuum dry at 110°C for 3h to obtain a catalyst precursor, and finally use 5 times the volume of nitrogen diluted hydrogen Reduction at 160°C for 3 hours at 150ml / min and filtration to obtain the finished Pd-Ce-Hf / C catalyst. According to ICP-AES analysis, the Pd content in the catalyst is 0.45wt%, the Ce content is 0.2wt% and the Hf content is 0.4wt%. , for the convenience of comparison, the resulting catalyst composition is listed in Table 1.

[0026] Catalyst evaluation: 18g of crude terephthalic acid containing 3300ppm p-carboxybenzaldehyde (4-CBA), 5wt% PX, 42g of water and 2g of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com