In-situ heat treatment method for realizing electron beam selective melting material increase manufacturing of metal parts

A technology of additive manufacturing and selective melting, which is applied in the directions of additive manufacturing, process efficiency improvement, and energy efficiency improvement. It can solve the problems of increasing production and manufacturing costs, and achieve the effect of improving surface finish and eliminating microscopic holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

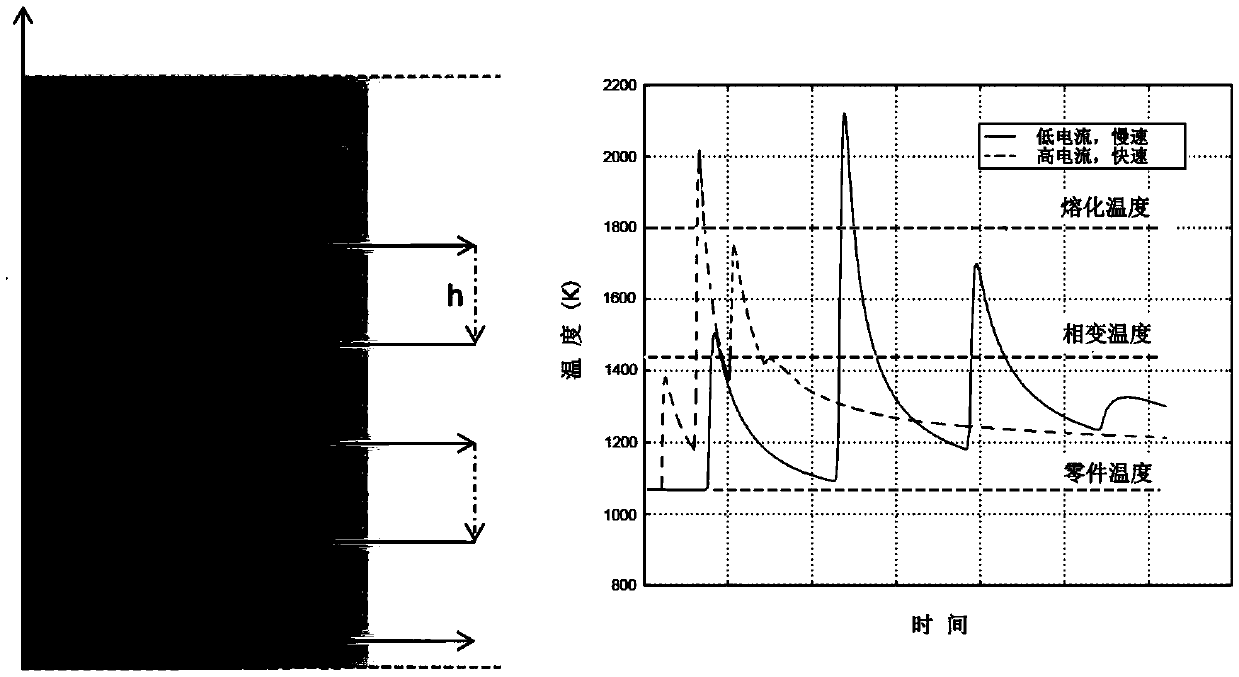

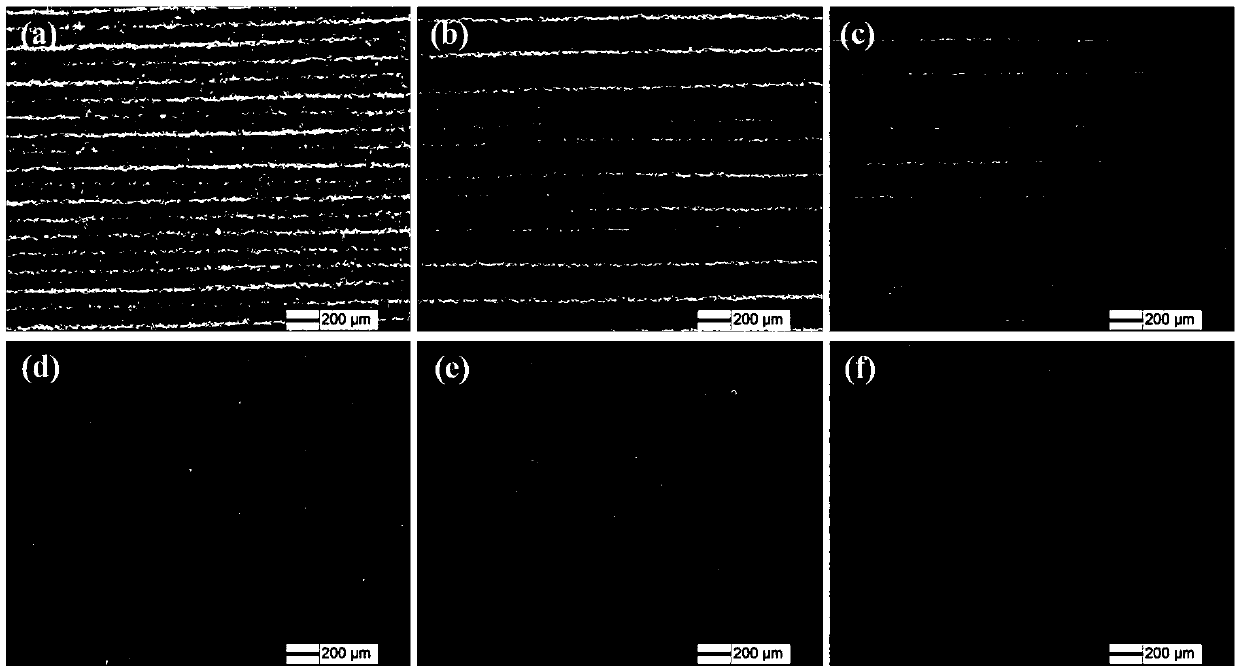

[0026] Example 1: In-situ heat treatment of TC4 alloy

[0027] EBM equipment is used to process six TC4 alloy test blocks at the same time, and the size is 20mm×20mm×80mm. One of the test blocks was processed by the normal process, the electron beam current was 4.5mA, the scanning speed was 700m / s, the FocusOffset value was 3, and no secondary remelting in-situ heat treatment was performed. For the remaining 5 test blocks, the electron beam FocusOffset values were set to 3, 10, 20, 40, and 60 for in-situ remelting treatment, and the electron beam current and scanning speed were not changed during the remelting process. figure 2 It is the surface morphology of TC4 alloy treated with different processing parameters. From figure 2 In (a), it can be seen that there are obvious electron beam scanning traces on the surface of the unremelted sample. After the second remelting treatment, the surface state of the sample changes, and the sample surface obtained when the FocusOffs...

Embodiment 2

[0031] Example 2: In-situ heat treatment of Inconel625 alloy

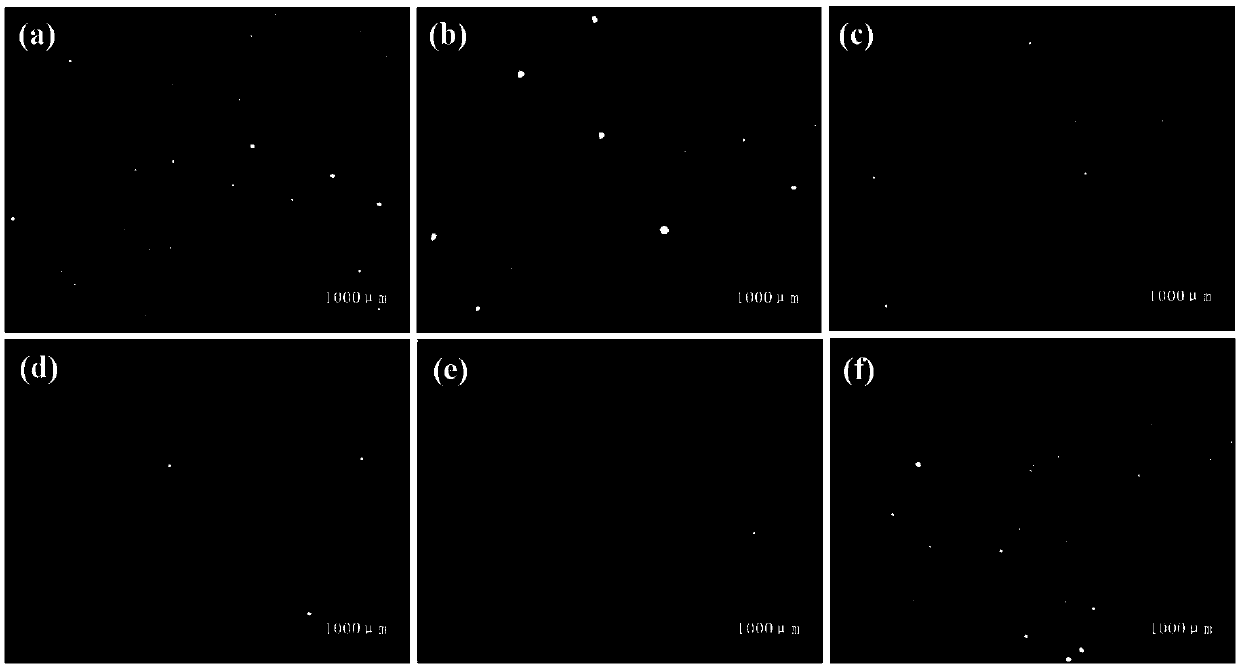

[0032] EBM equipment is used to process 4 pieces of Inconel625 alloy test blocks at the same time, and the sizes are all One of them (denoted as 1# test block) was processed by normal process, the processing electron beam current was 4.5mA, the scanning speed was 500m / s, the FocusOffset value was 20, and no secondary remelting in-situ heat treatment was performed. The parameters of the in-situ heat treatment for the other two test blocks are respectively: the electron beam current is 4.5mA, the scanning speed is 1000m / s, and the FocusOffset value is 20 (denoted as 2# test block); the electron beam current is 4.5mA, and the scanning speed is 400m / s, FocusOffset value is 40 (recorded as 3# test block). Figure 6 The cross-sectional metallographic pictures and Figure 7 The electron backscatter diffraction (EBSD) images are the microscopic analysis results of the Inconel625 alloy before and after the remelting tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com