Auxiliary working warehouse for automatic welding of large storage tanks and its usage method

A technology for auxiliary work and large storage tanks, applied in welding/cutting auxiliary equipment, auxiliary devices, auxiliary welding equipment, etc., can solve problems such as difficulty in tracking ultra-wide ring plates, achieve convenient monitoring of automatic welding conditions, improve construction efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

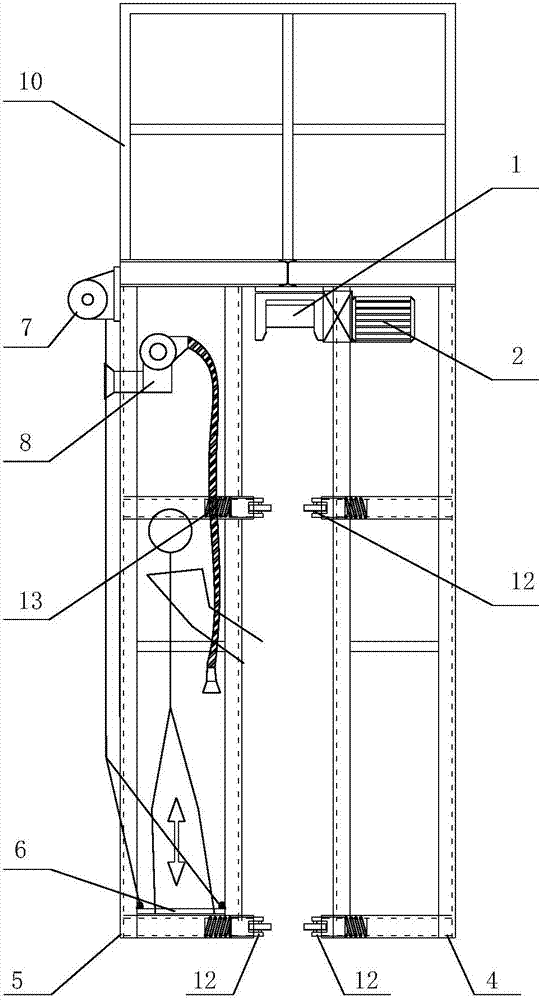

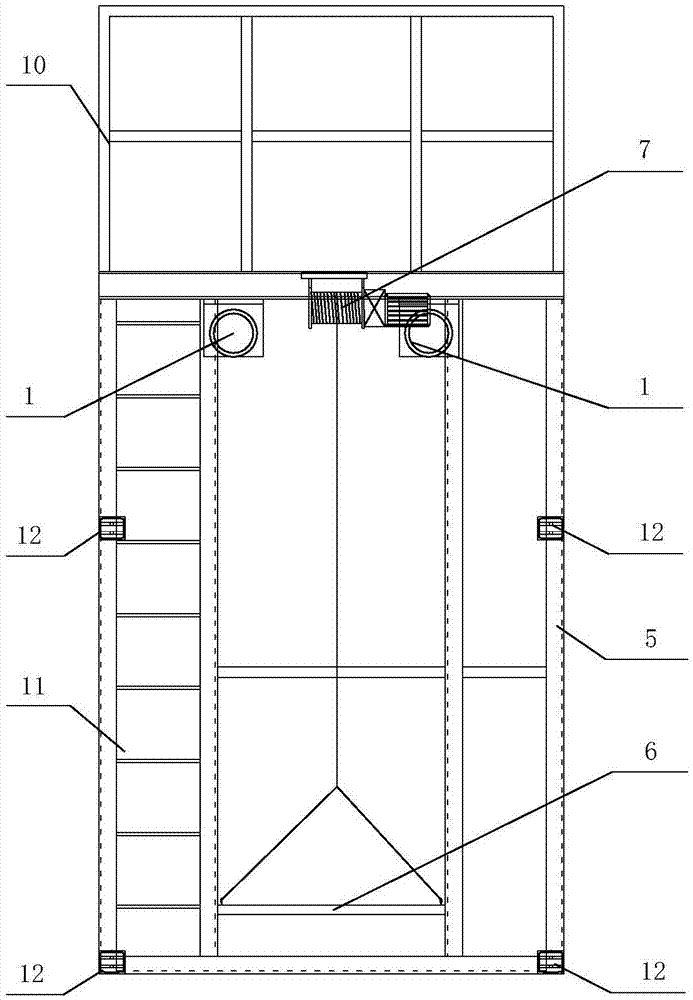

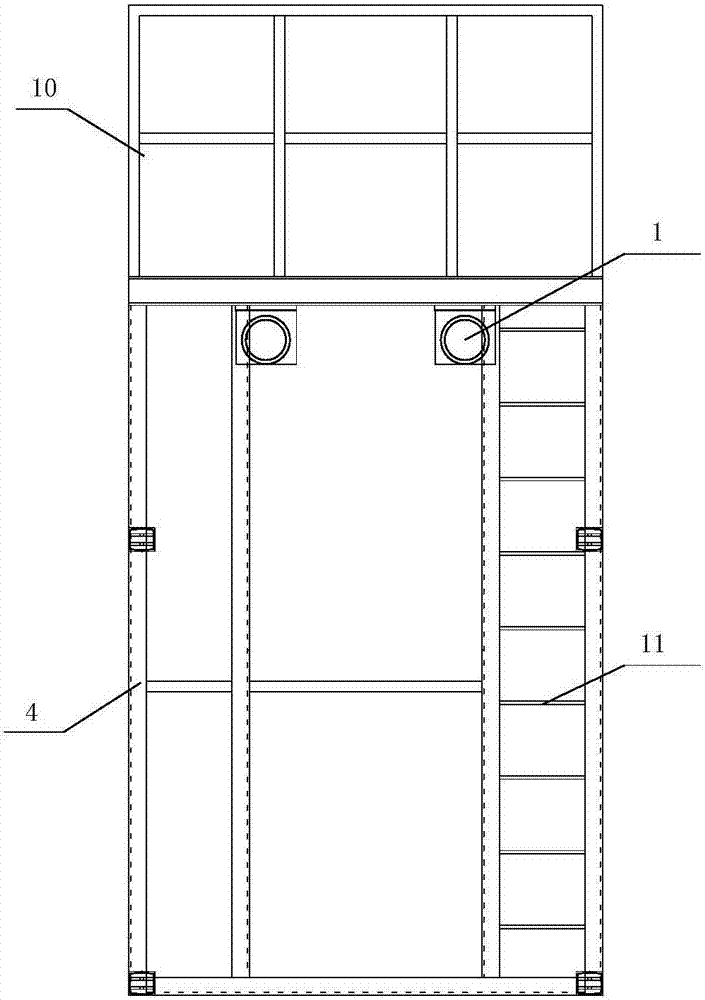

[0042] see Figure 1 to Figure 5 , the present embodiment discloses a large-scale storage tank automatic welding auxiliary working warehouse, which is mainly used for monitoring the construction of automatic vertical seam welding of storage tanks and manual repair welding operations. The large-scale storage tank automatic welding auxiliary working chamber includes a rectangular frame, a horizontally moving roller 1 of the ring plate, a motor 2, and a reduction box (not shown). The rectangular frame is divided into a front chamber 4 and a rear chamber 5. There is a space between the front and rear chambers 4 and 5 for the storage tank ring plate hereinafter referred to as the ring plate 3 to extend into, and the top of the front and rear chambers 4 and 5 is fixed with the ring plate transverse Moving the roller 1, the motor 2 drives the circle plate lateral movement roller 1 to rotate through the reduction box, so that the entire large storage tank automatic welding auxiliary w...

Embodiment 2

[0049] read on Figure 1 to Figure 5 , the present invention also discloses a method for using the auxiliary working warehouse for automatic welding of large storage tanks described in Embodiment 1, which includes the following steps:

[0050] The first step is to set up the large storage tank automatic welding auxiliary working warehouse on the ring plate 3, and the horizontal moving roller 1 of the ring plate is stuck on the top of the ring plate 3, and the front and rear warehouses 4 and 5 are located in the ring plate On the inner and outer sides of the plate 3, an automatic welding machine (not shown) and a welding head (not shown) are placed on the auxiliary working chamber for automatic welding of large storage tanks;

[0051] In the second step, the operator enters the rear compartment 5;

[0052] In the third step, the motor 2 drives the ring plate to move the roller 1 laterally, so that the entire large storage tank automatic welding auxiliary working chamber moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com