Detection system for tool chattering in milling and detection method thereof

A milling processing and detection system technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficulty in obtaining vibration signals, low efficiency, and influence of chatter signal analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

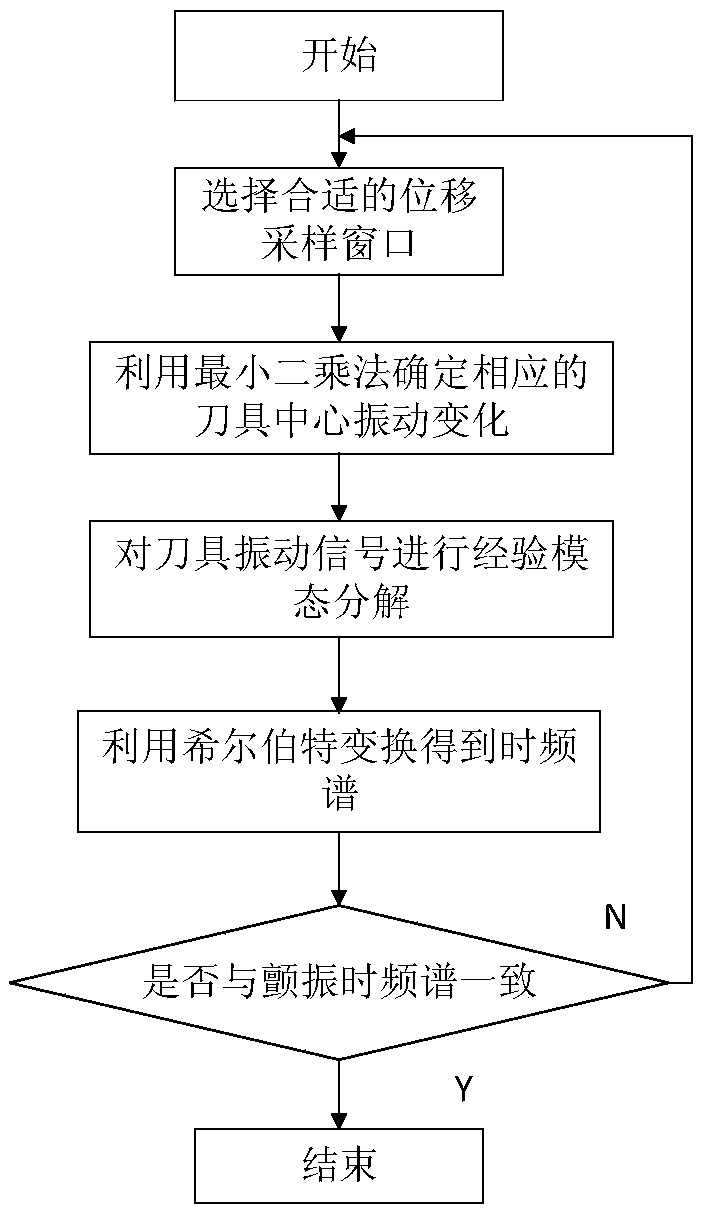

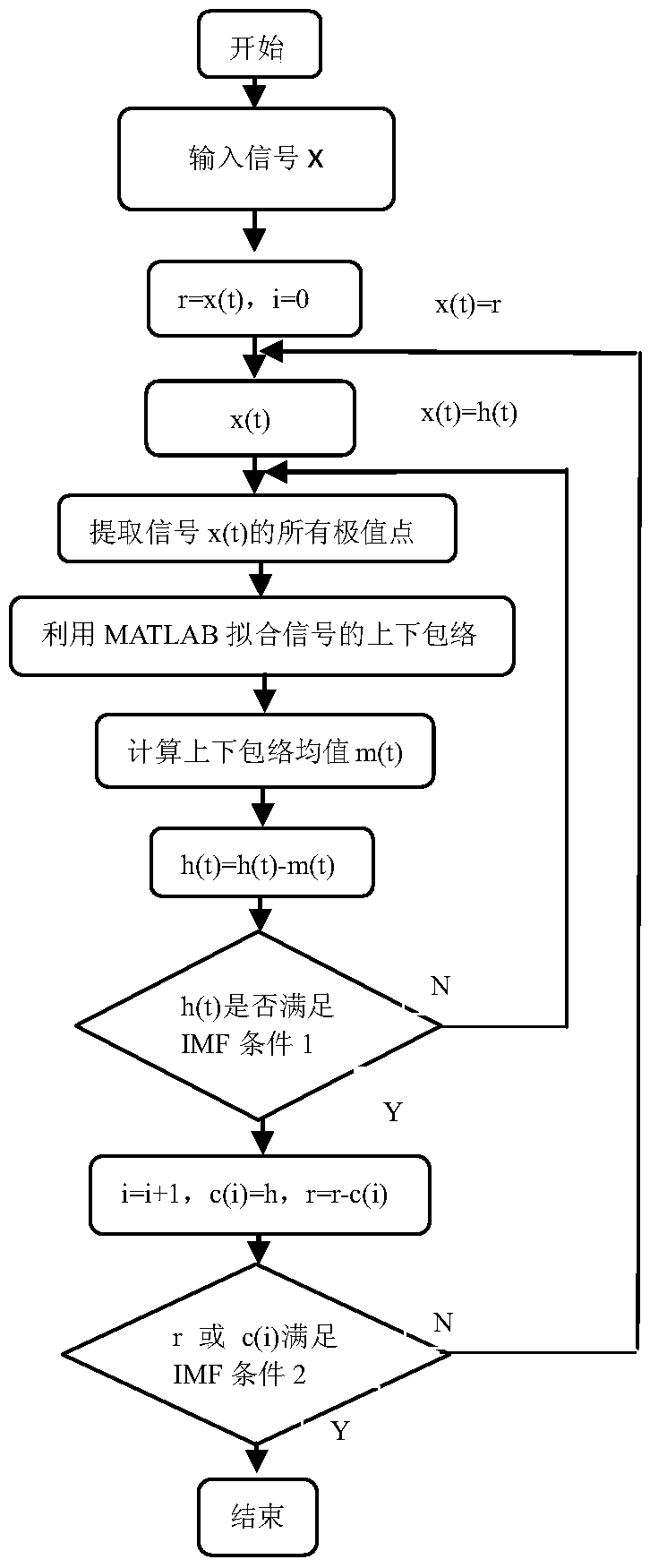

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

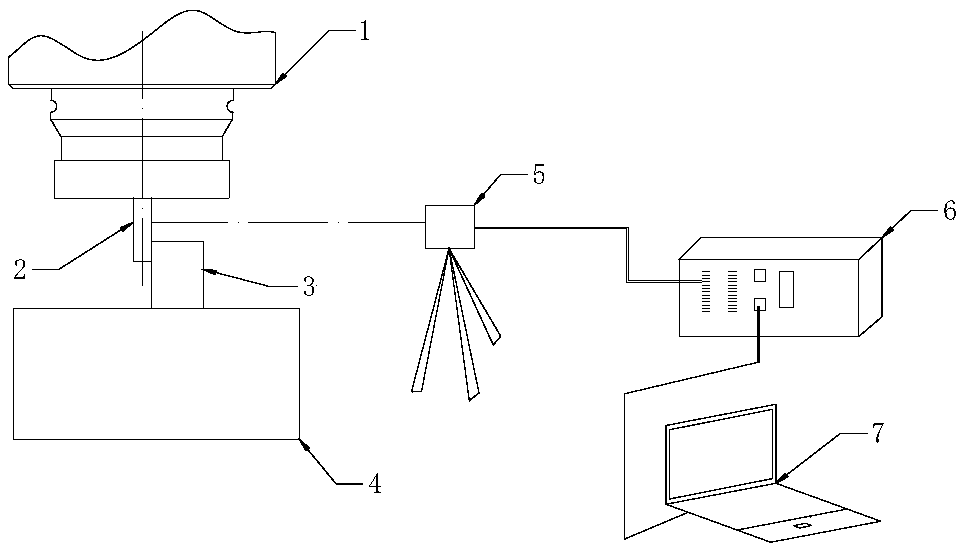

[0038] Such as figure 2 As shown, the detection system includes a displacement detection unit, a data acquisition unit, and a central processing unit. In this embodiment, a multi-point laser displacement sensor is arranged around the CNC machine tool. During the processing, the laser displacement sensor measures multiple points on the tool surface at each moment.

[0039] The multi-point laser displacement sensor is connected to the central processing unit through a USB data transmission line, and the displacement signal detected by the sensor is transmitted to the central processing unit to collect the corresponding data signal.

[0040] The displacement signal is expressed as: X = [ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com