Braking system for freight train

A freight train and brake system technology, applied in the field of freight train brake systems, to achieve the effects of prolonging service life, reducing wear, and reducing use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

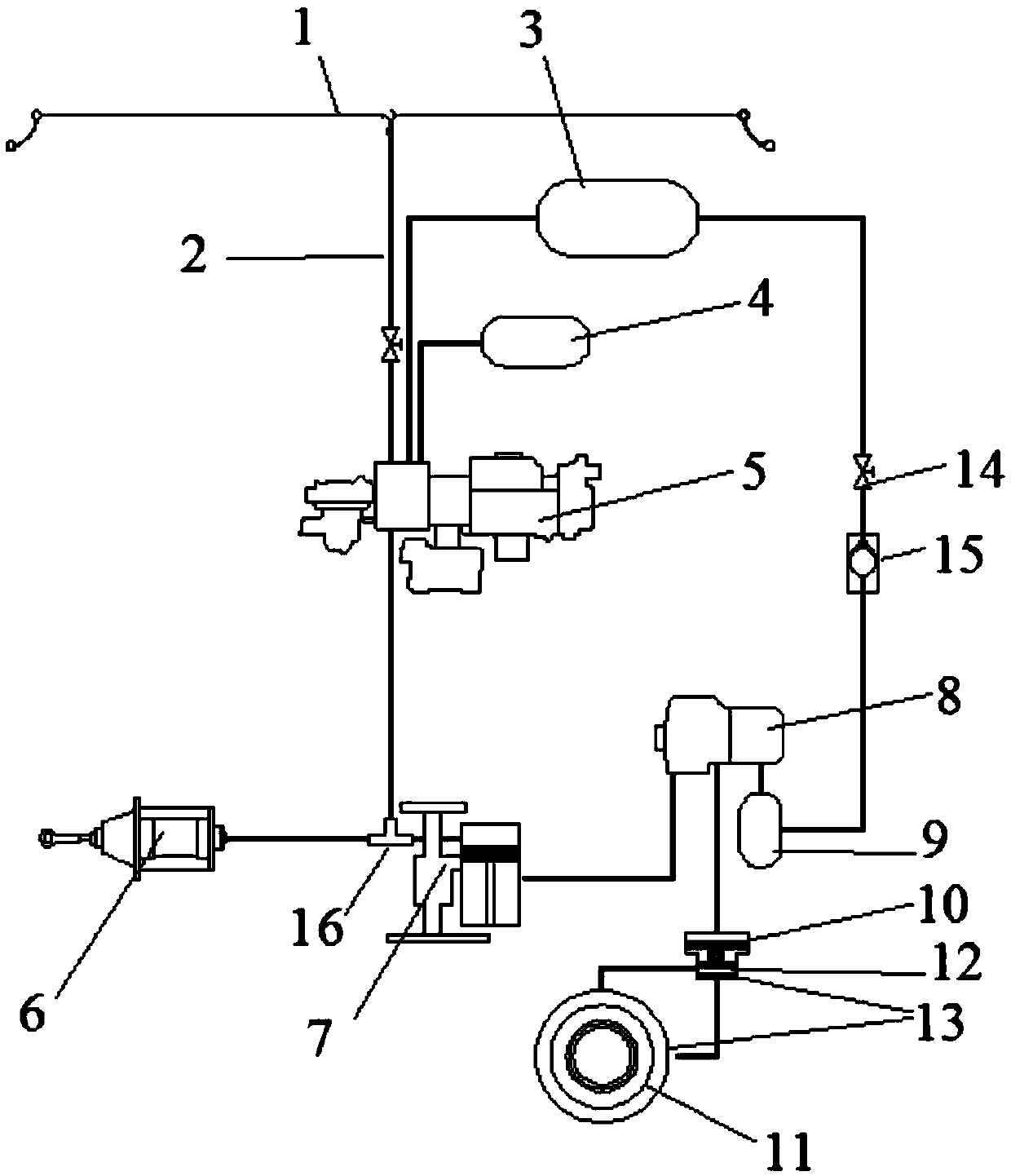

[0039] A braking system for freight trains such asfigure 1 As shown, it includes the main brake pipeline composed of train pipe 1, auxiliary air cylinder 3, distribution valve 5, acceleration release air cylinder 4 and brake cylinder 6. The brake cylinder 6 is connected to the basic brake device of the truck and the brake shoes, and is used to generate the main braking torque to the wheels. The brake system also includes an auxiliary brake pipeline connected to the distribution valve 5, and the auxiliary brake pipeline includes an empty-load vehicle control valve assembly 7, Relay valve 8, gas-liquid conversion booster valve 10, fuel tank 12 and hydraulic damper 11, relay valve 8 is also connected to air supply cylinder 9 that provides pressure air, and empty-load vehicle control valve assembly 7 is also connected to three-way pipe joint 16. The other two ends of the three-way pipe joint 16 are respectively connected to the brake cylinder 6 and the distribution valve 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com