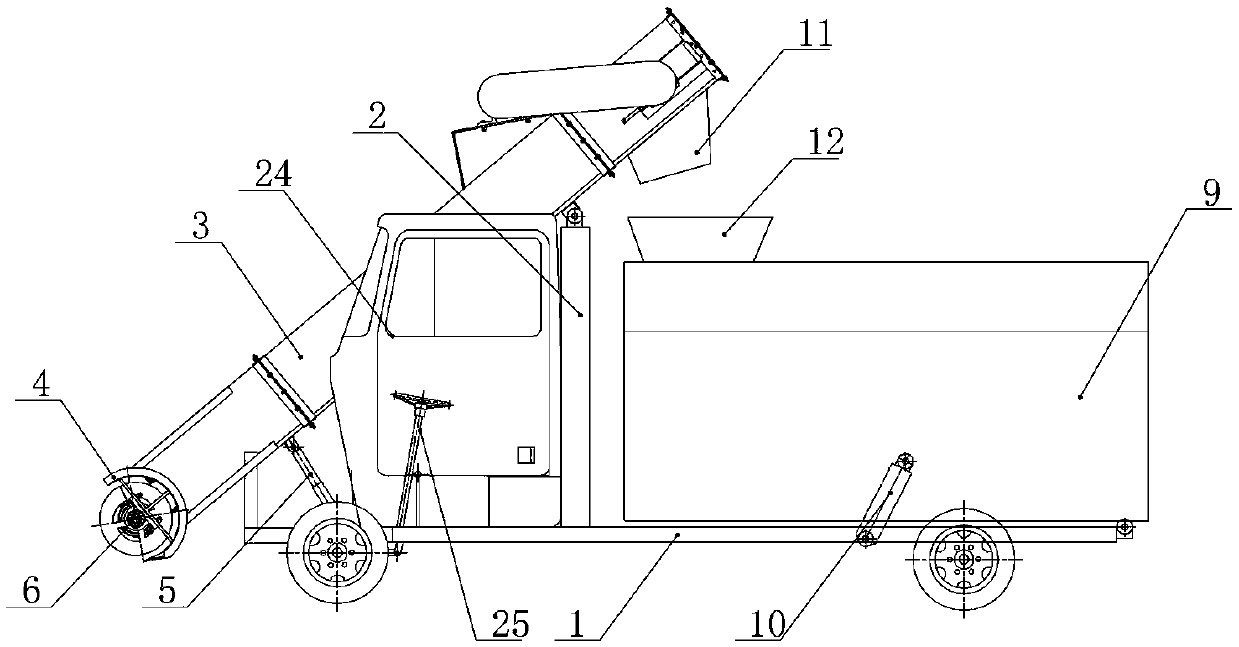

Automatic loading-unloading environment-friendly electric cleaning and transporting vehicle

A technology of automatic loading and unloading and clearing vehicles, which is applied in the direction of loading/unloading, transportation and packaging, garbage storage, etc., and can solve the problem that one person cannot realize automatic operation of picking, transportation, and unloading, and the cost of transportation operation (energy consumption) is high. Problems such as not being too high, affecting the operating efficiency of the operating enterprise, etc., to achieve the effect of improving the production and operating environment, saving labor costs, improving structural performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

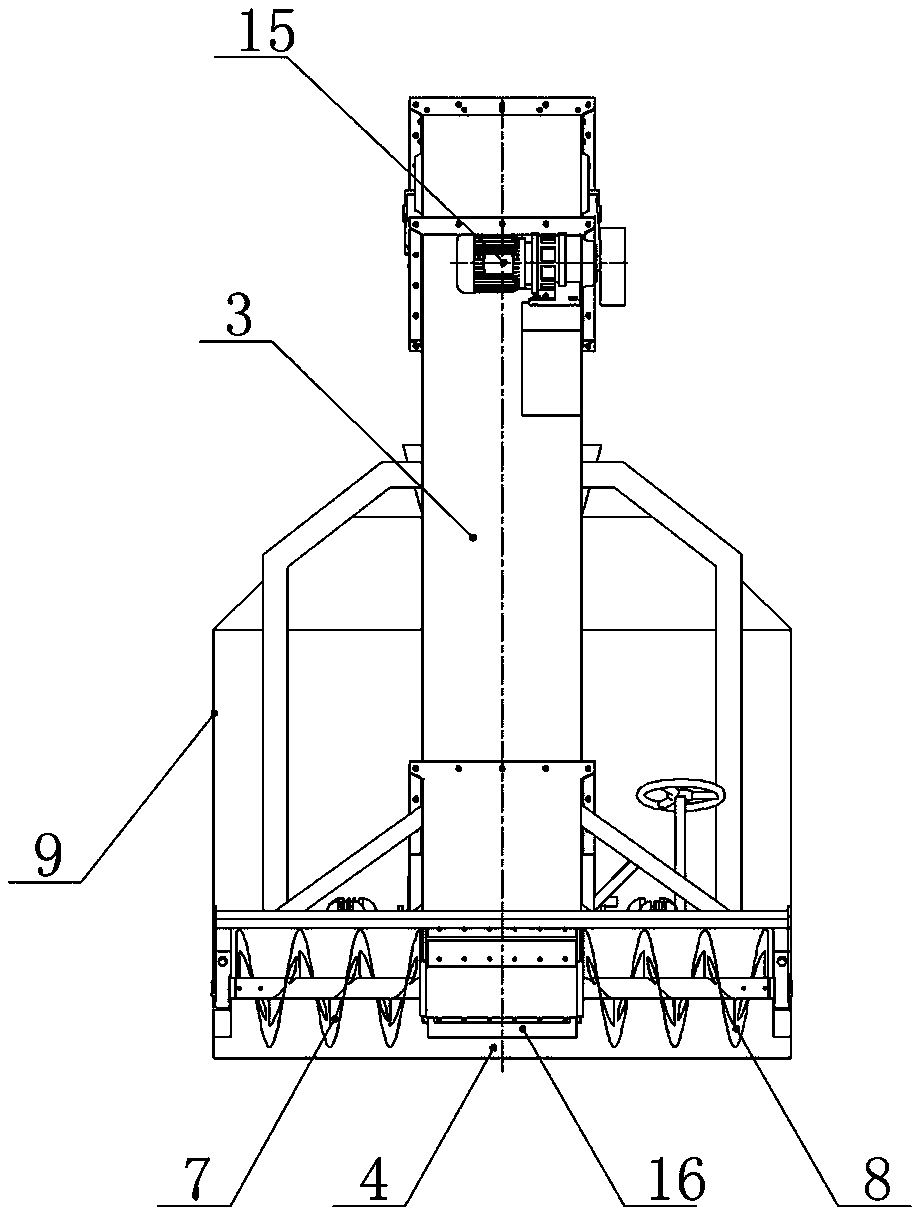

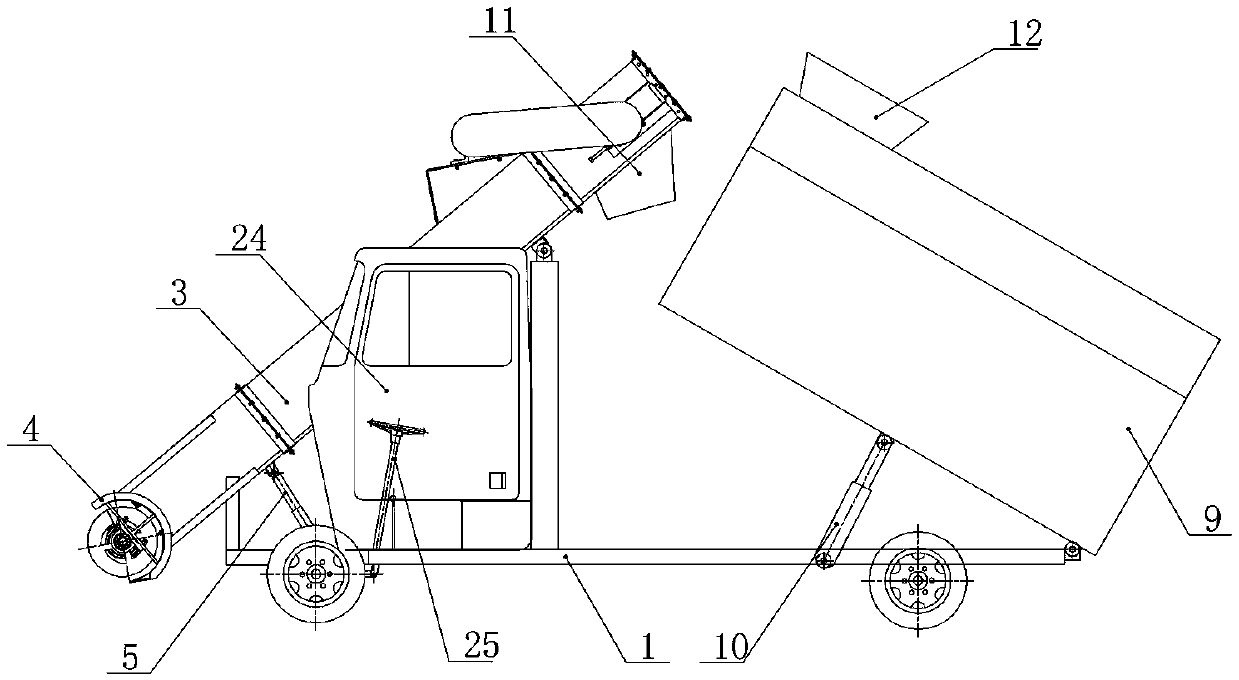

[0030] Embodiment two: see Figure 1-Figure 6 , Figure 8 and Figure 10 The structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the section of the transmission cylinder is rectangular, and the lifting and feeding mechanism includes a transmission chain 17, respectively The driving sprocket and driven sprocket 18 arranged at both ends of the transmission chain, the hoisting motor 15 driving the driving sprocket, and the scrapers 16 arranged at equal intervals on the transmission chain, the outer ends of the scraper 16 and the transmission The inner wall of the cylinder body 3 is matched and bonded, and the driven sprocket 18 is arranged in the material collection groove 4 at the lower end of the transmission cylinder body, and is fixedly arranged on the material collection rotating shaft 6 .

[0031] The working principle of the present invention is:

[0032] In the normal walking stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com