A kind of green preparation method of graphene

A graphene and graphene suspension technology, applied in the field of materials, can solve the problems of unfavorable large-scale production and application, dangerous use process, high energy consumption, etc., and achieve high safety and reliability, simple raw materials, and low hydrothermal reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is a preferred embodiment.

[0024] (1) Disperse 60mg of GO in 60mL aqueous solution, and ultrasonicate for 1h to form a brown-yellow graphene oxide suspension;

[0025] (2) add 3mL in the graphene oxide suspension that step (1) obtains, the sodium humate solution of 5mol / L, stir;

[0026] (3) Transfer the solution obtained in step (2) into a 100mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 80°C for 24h;

[0027] (4) The product obtained in step (3) is washed with alcohol and distilled water at 8000 rpm for 5 times, each time for 3 min, and the product obtained is dried to obtain a graphene product.

Embodiment 2

[0029] (1) Disperse 300mg of GO in 60mL aqueous solution, and ultrasonicate for 1h to form a brown-yellow graphene oxide suspension;

[0030] (2) add 5mL in the graphene oxide suspension that step (1) obtains, the sodium humate solution of 5mol / L, stir;

[0031] (3) Transfer the solution obtained in step (2) into a 100mL hydrothermal reaction kettle, and perform a hydrothermal reaction at 100°C for 18h;

[0032] (4) The product obtained in step (3) is washed with alcohol and distilled water at 10,000 rpm for 6 times, each time for 5 min, and the product obtained is dried to obtain a graphene product.

Embodiment 3

[0034] (1) Disperse 30 mg of GO in 60 mL of aqueous solution, and ultrasonicate for 0.5 h to form a brown-yellow graphene oxide suspension;

[0035] (2) add 1mL in the graphene oxide suspension that step (1) obtains, the sodium humate solution of 5mol / L, stir;

[0036] (3) Transfer the solution obtained in step (2) into a 100mL hydrothermal reaction kettle, and perform a hydrothermal reaction at 120°C for 12h;

[0037] (4) The product obtained in step (3) is washed with alcohol and distilled water at 8000 rpm for 5 times, each time for 3 min, and the product obtained is dried to obtain a graphene product.

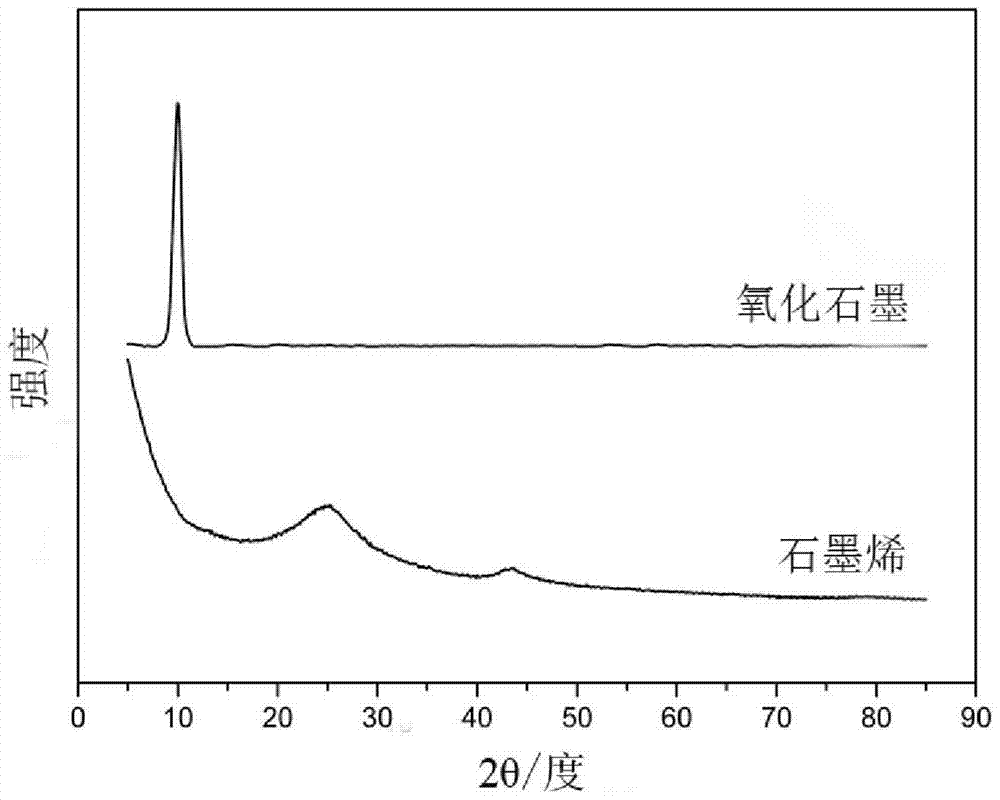

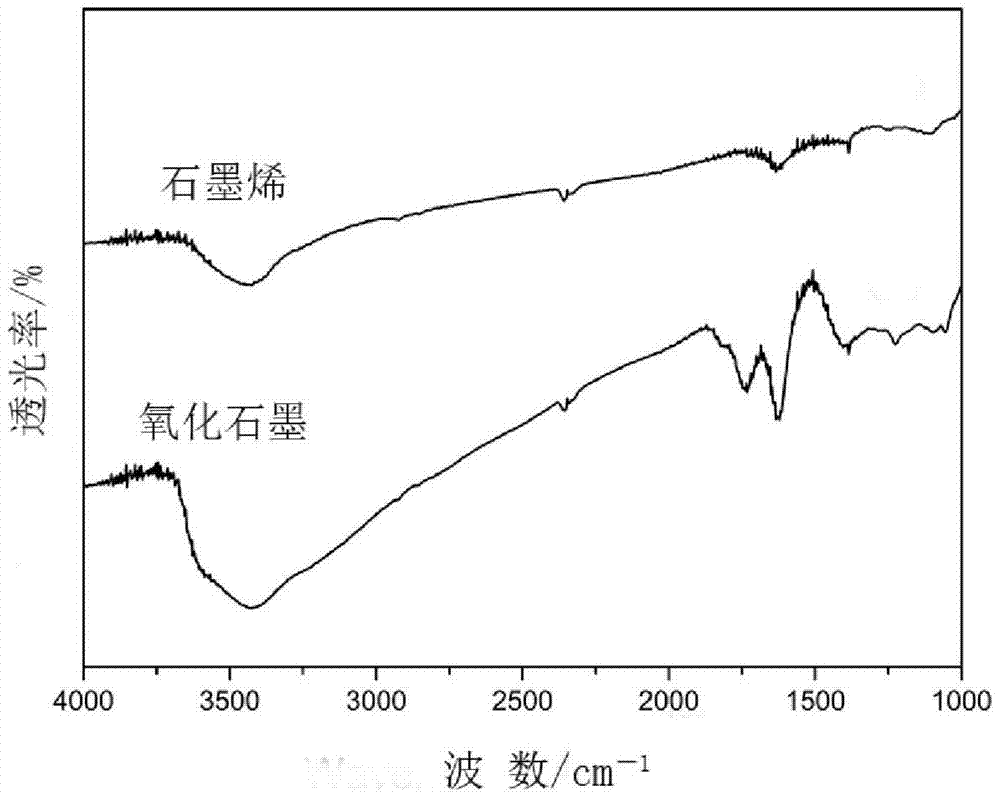

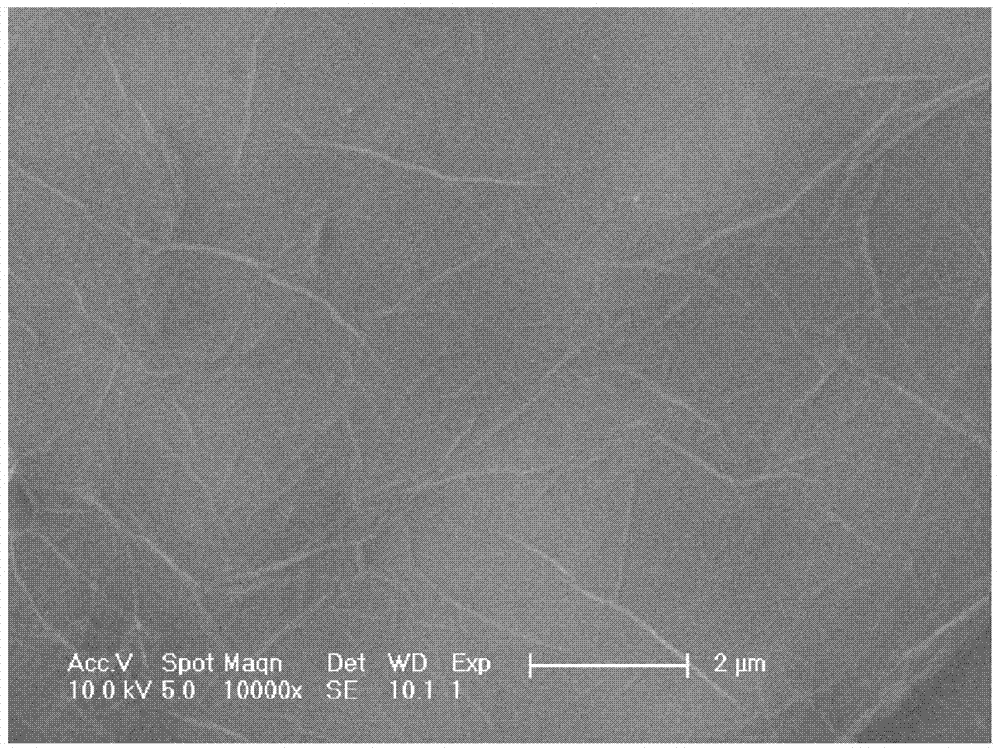

[0038] attached figure 1 It is the X-ray diffraction (XRD) spectrogram of graphene and graphene oxide obtained in Example 1 of the present invention. Depend on figure 1 It can be seen that the graphene oxide curve has a strong diffraction peak around 2θ of about 10°, that is, the diffraction peak of the graphite oxide (001) plane. After reduction by sodium humate, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com