Water purifier

A water purifier and concentrated water technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. problem, to achieve the effect of reducing the amount and reducing the amount of water produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

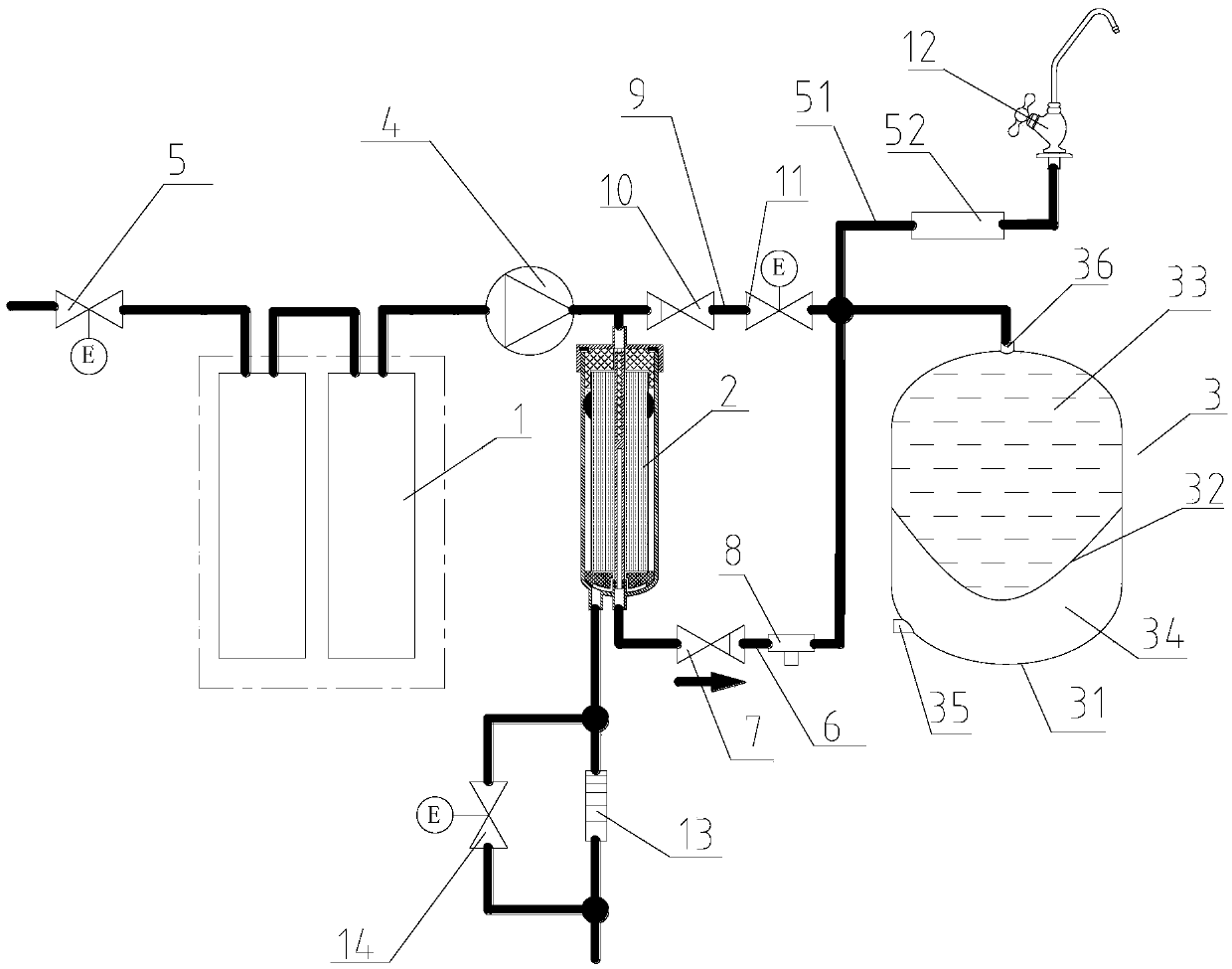

[0032] Such as figure 1 Shown is a schematic structural diagram of a water purifier provided by the present invention. The water purifier in this embodiment includes: a first pretreatment filter element 1 , a membrane processor 2 , a pressure water storage tank 3 and a water pump 4 . The pressure water storage tank 3 includes: a housing 31 and a flexible diaphragm 32 . The flexible diaphragm 32 is arranged in the middle of the housing 31 , and its periphery is sealed and fixed with the inner wall of the housing 31 , dividing the inner space of the housing 31 into a water cavity 33 and an air cavity 34 . The housing 31 is provided with an air nozzle 35 which communicates with the air cavity 34 . A water nozzle 36 is also provided on the housing 31 , which communicates with the water chamber 33 .

[0033] The water inlet of the first pretreatment filter element 1 is connected to the water source, and the water outlet is connected to the inlet of the membrane processor 2 . The...

Embodiment 2

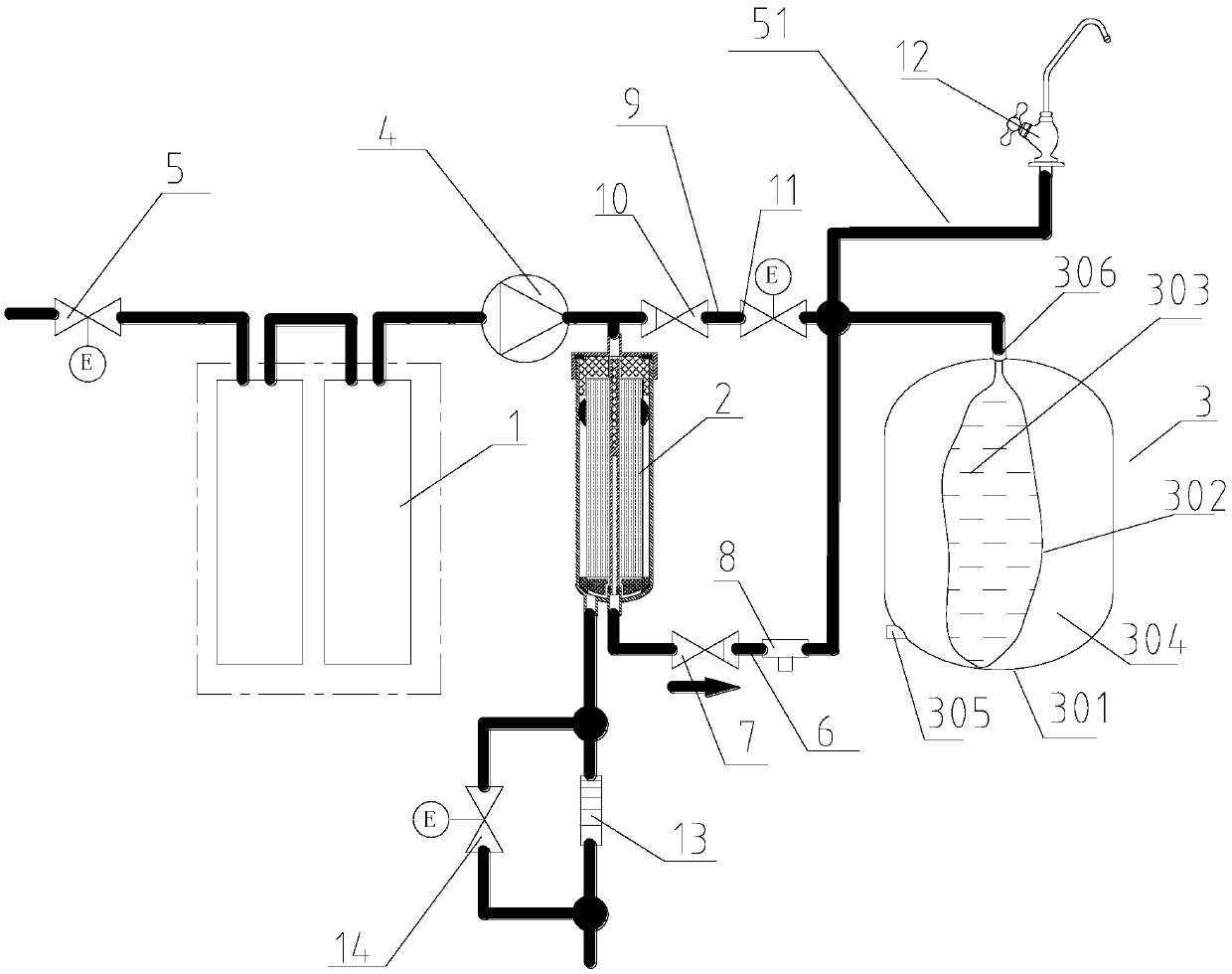

[0040] Such as image 3 As shown, it is a structural schematic diagram of another water purifier provided by the present invention. The difference between the water purifier in this embodiment and the water purifier in Embodiment 1 is that the water purifier in this embodiment The pressure water storage tank includes: a housing 301 and a bag-shaped flexible diaphragm 302 . The bag-shaped flexible diaphragm 302 is arranged inside the housing 301 , and the opening of the bag-shaped flexible diaphragm 302 is sealed and fixed with the faucet 306 on the housing 301 , and the faucet 306 communicates with the bag-shaped flexible diaphragm 302 . The bag-shaped flexible membrane 302 divides the inner space of the housing 301 into a water cavity 303 and an air cavity 304 . The inside of the bag-shaped flexible diaphragm 302 is a water chamber 303 , and the outside is an air chamber 304 . The housing 301 is provided with an air nozzle 305 which communicates with the air cavity 304 . T...

Embodiment 3

[0042] Such as Figure 4 As shown, it is a structural schematic diagram of another water purifier provided by the present invention. The difference between the water purifier in this embodiment and the water purifier in the second embodiment is that the water purifier in this embodiment also includes The inlet of the second pretreatment filter element 15 is connected to the water source, and the outlet thereof is connected to the water inlet valve 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com