Descaling anticrustator and use method thereof

An anti-scaling agent and anti-scaling technology, applied in the field of descaling and anti-scaling agents, can solve the problems of secondary scaling of calcium and magnesium plasma, damage to the service life of equipment, diversion of hot water for other purposes, etc. The effect of reducing dust emissions and saving fuel

Inactive Publication Date: 2016-04-20

汪保安

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the above-mentioned alkaline is used for descaling, it takes a long time and the effect is not ideal

Regardless of pickling or alkali washing, the scale detaches into flakes, which is a serious phenomenon of pipe blockage. The existing descaling method also has the method of acid washing and then alkali washing, but this method not only causes serious corrosion to steel damage and damage the service life of the equipment, and the traditional alkali antiscaling agent still has the problem of secondary scaling during use (the calcium and magnesium plasma dissolved in the circulating water will be lost in the boiler and pipeline with the loss of temperature, time and steam. Hard-to-dissolve scales form on the surface)

[0006] During the heating period, because the circulating water in the radiator is relatively clean, there is a phenomenon that residential users release the hot water in the heating for other purposes, and when the boiler and piping system lose water, the cold water is replenished, and the cold water must be replaced by fuel. Running hot, a lot of fuel will be wasted in winter

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

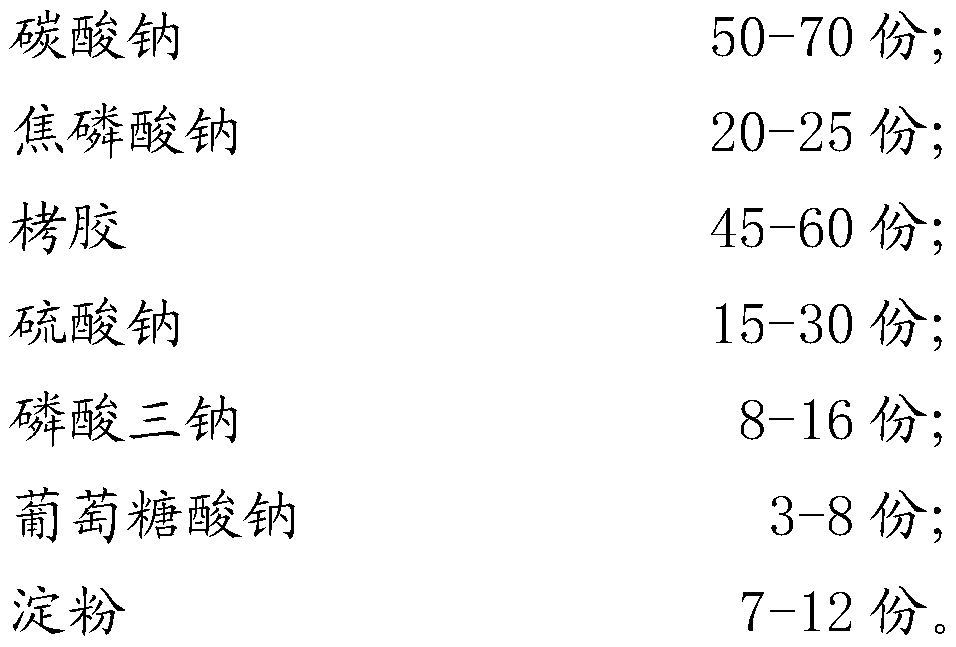

[0039] Prepare the descaling and antiscaling agent according to the weight ratio of the following ingredients:

[0040]

[0041]

Embodiment 2

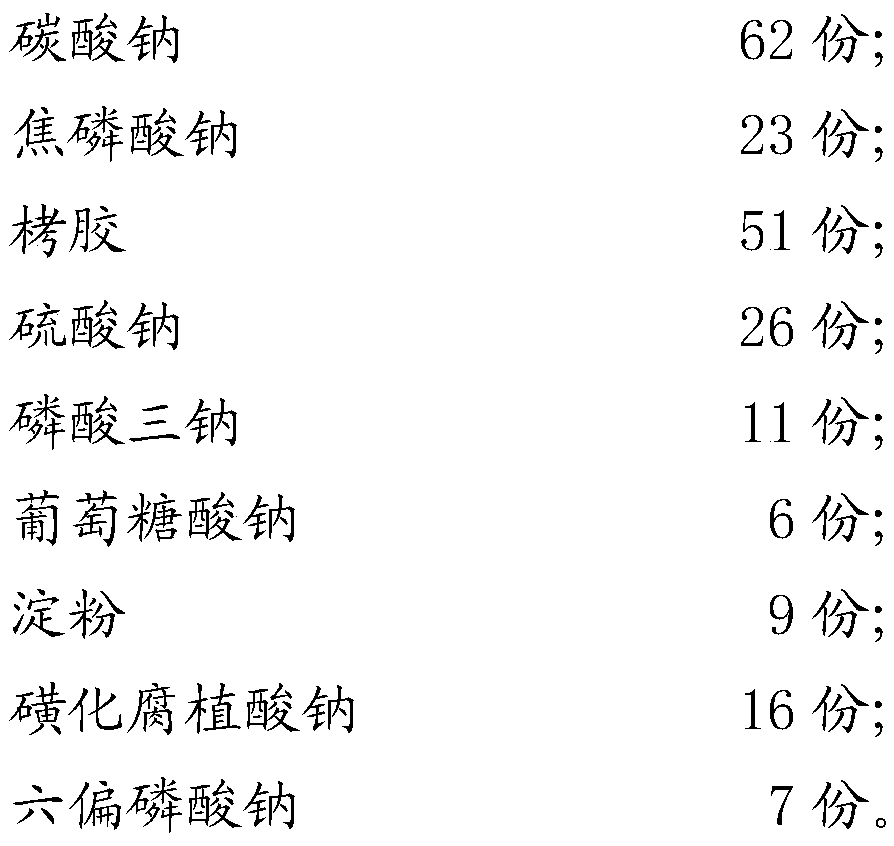

[0043] Prepare the descaling and antiscaling agent according to the weight ratio of the following ingredients:

[0044]

Embodiment 3

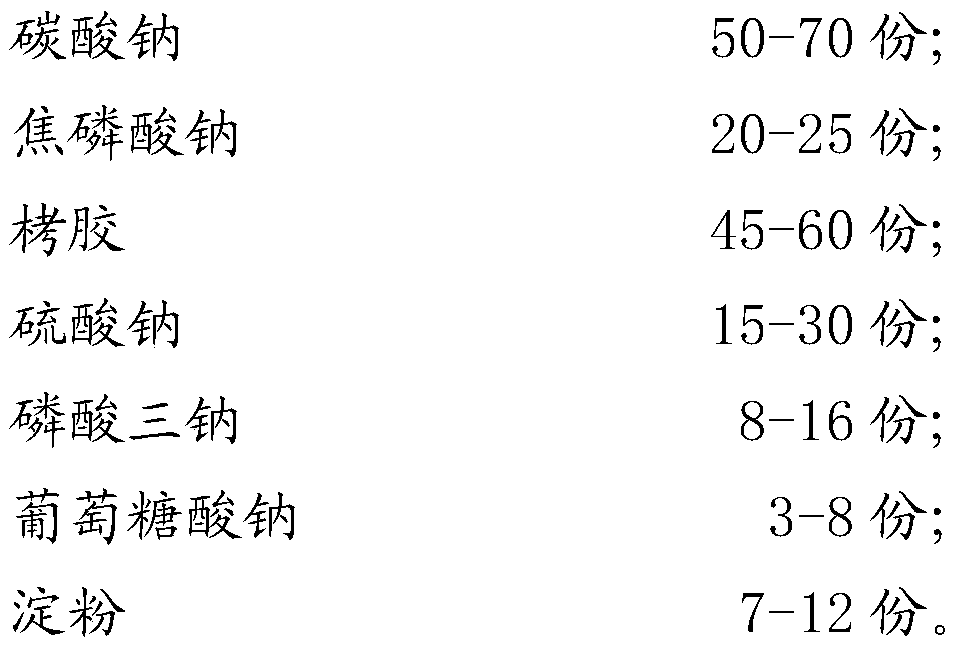

[0046] Prepare the descaling and antiscaling agent according to the weight ratio of the following ingredients:

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a descaling anticrustator, which is prepared from the following components according to parts by weight: 50-70 parts of sodium carbonate, 20-25 parts of sodium pyrophosphate, 45-60 parts of tanning extracts, 15-30 parts of sodium sulfate, 8-16 parts of trisodium phosphate, 3-8 parts of sodium gluconate and 7-12 parts of starch. The descaling anticrustator has the beneficial effects that a descaling and antiscaling effect is improved, secondary scaling is avoided, and the descaling anticrustator has the advantages of environment protection, no toxicity, no taste, efficiency and energy saving.

Description

technical field [0001] The invention relates to the field of chemical industry, in particular to a descaling and antiscaling agent and a using method thereof. Background technique [0002] As a traditional winter heating equipment, boilers are very common in our country. The existing boiler feed water treatment is unqualified, which will cause great corrosion to the boiler, and will cause hard scale to form on the heating surface of the inner wall of the boiler. [0003] The boiler and other heating equipment generate scale because the boiler feed water contains a certain amount of calcium, magnesium ions and other heavy metal ions. During operation, the calcium and magnesium ions absorb heat and chemically react with carbon dioxide dissolved in the water to form insoluble substances. . And the water is heated in the furnace to generate water vapor, the concentration of calcium and magnesium carbonate in the furnace water is getting higher and higher, and the solubility of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F5/08

CPCC02F5/08

Inventor 汪保安

Owner 汪保安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com