Preparation method of large-granule cerous oxalate precursor

A technology of cerium oxalate and precursor, which is applied in the field of chemical materials, can solve the problems of small particles of precursor cerium oxalate, nucleation rate, and unsatisfactory growth rate, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in combination with specific embodiments.

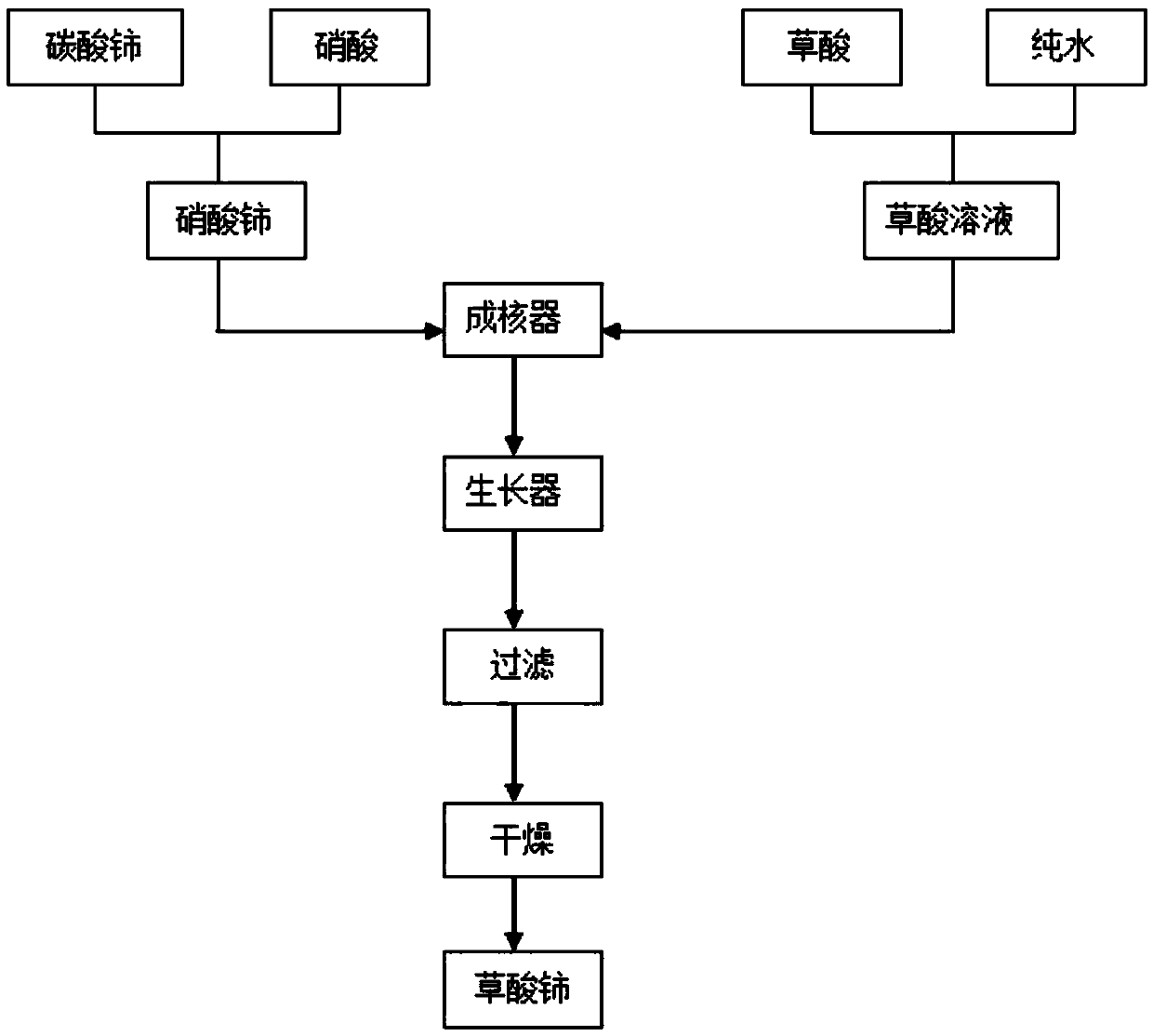

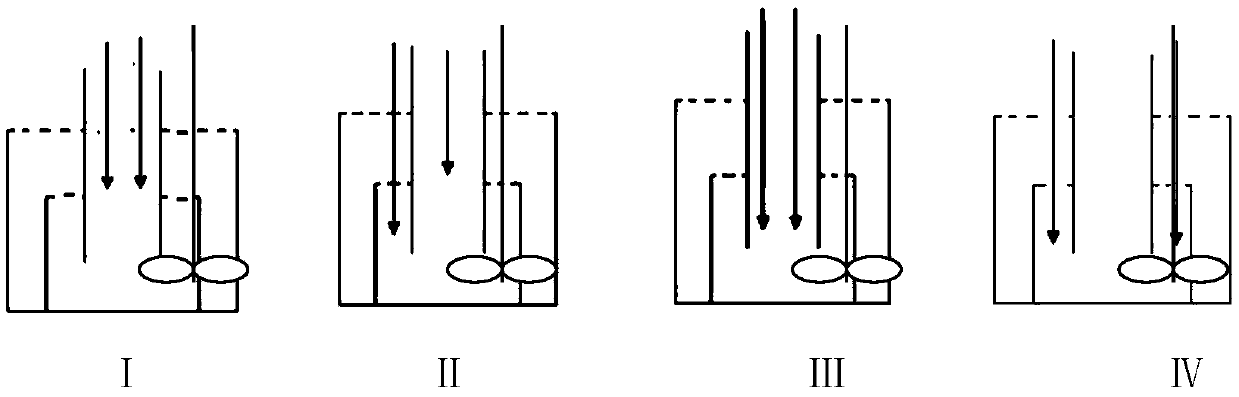

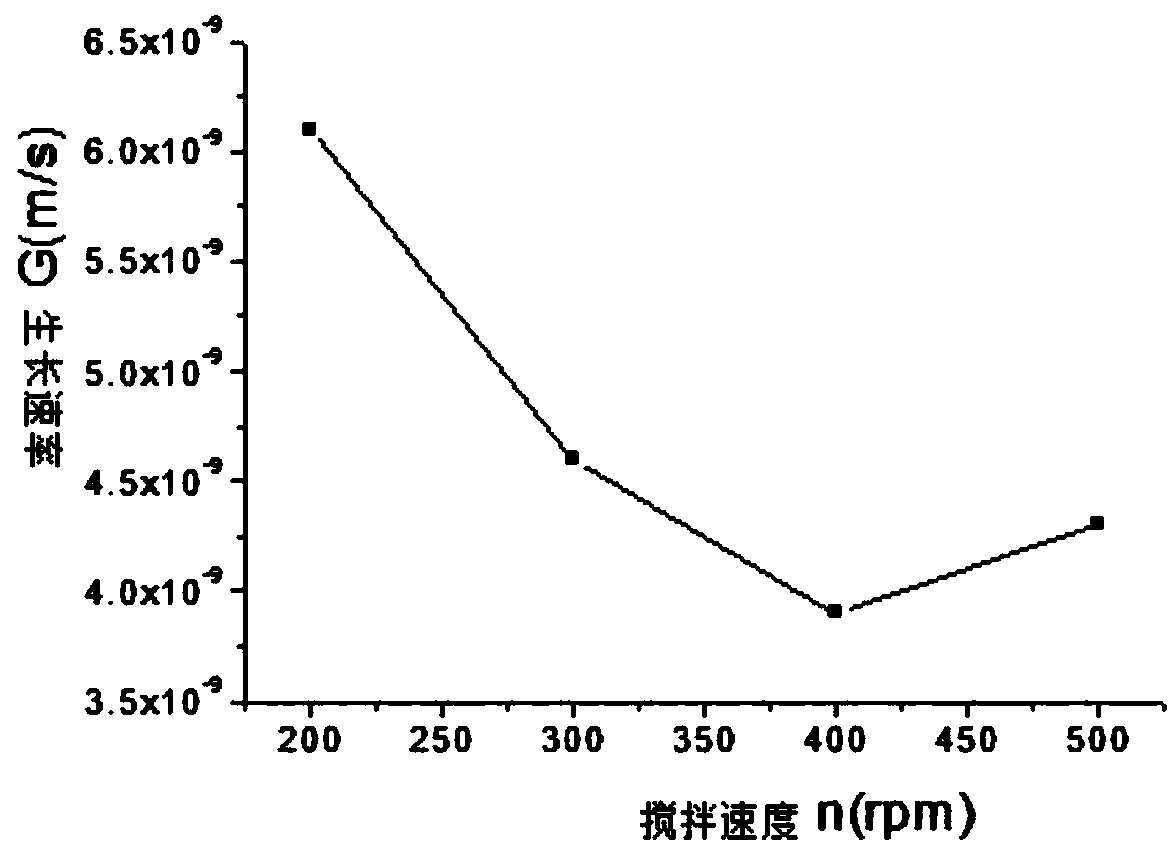

[0026] The invention divides the precipitation process into two processes of nucleation and growth through a special precipitator, and studies the influence of different operating conditions on the precipitation kinetic parameters (nucleation rate and growth rate); simultaneously studies the nucleation process and the growth process Influence of various factors on particle agglomeration, the rare earth cerium oxide precursor cerium oxalate (C 6 Ce 2 o 12 ) preparation method and the control method of cerium oxalate aggregates, the inventor has obtained the optimal production method of the large particle cerium oxalate precursor according to a large number of theoretical basis and experimental verification, and using a self-made nucleator, the steps of the present invention are as follows figure 1 Shown:

[0027] Step 1: Prepare cerium carbonate solution Ce(NO 3 ) 3 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com