Method for preparing biodiesel from alage cultured by exhaust gas and ash of power plant as well as system

A biodiesel and algae technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, specific-purpose bioreactors/fermenters, etc., can solve problems such as complex equipment structure, low energy utilization efficiency, waste of resources, etc. , to achieve the effect of reducing environmental pollution, improving energy utilization efficiency, and solving processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

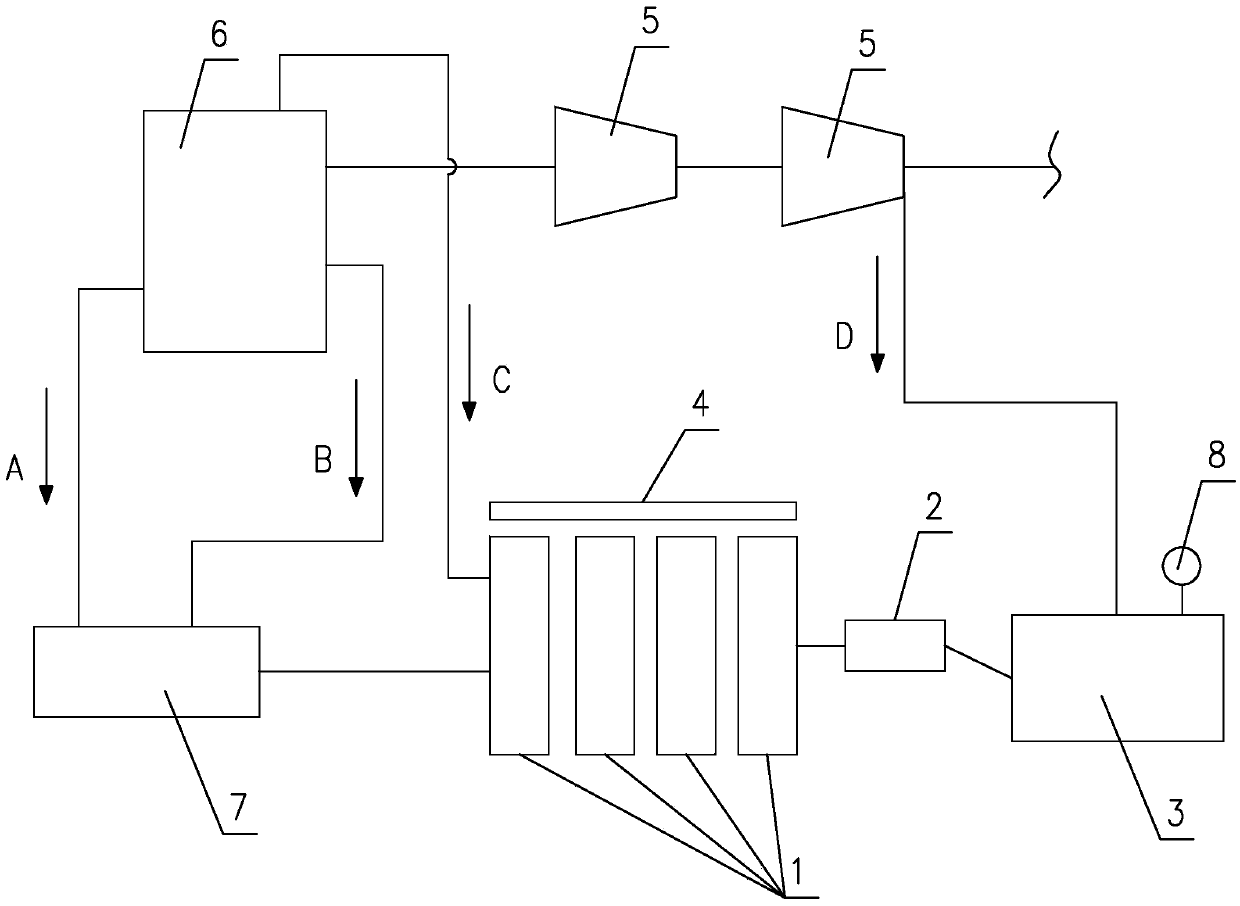

[0034] The present invention is a method for producing biodiesel by cultivating algae with smoke exhaust and ashes from a power plant, comprising the following steps:

[0035] ⑴ Modulation of algae culture solution: the ash produced by the combustion of power plant boilers and boiler circulating water are used as the main components of the algae culture solution to prepare the algae culture solution;

[0036] ⑵Cultivate algae: transport the algae culture solution to the algae culture container, divert the flue gas exhausted from the power plant boiler, and divert the CO 2 Send it into the algae culture container, and provide the culture conditions required for algae culture to carry out algae culture. The culture conditions include light intensity, light cycle, temperature, CO2 concentration and the pH value of the algae culture solution.

[0037] (3) Making algae pulp: crushing and cutting the macroalgae in the cultivated mature algae group, and stirring and mixing with the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com