Pipe induction heating equipment inductor

An induction heating device and induction heating coil technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as inability to maintain constant temperature and reduce product quality, and achieve elimination of residual stress, improvement of product quality, and improvement of welding The effect of seam structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

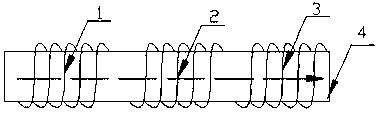

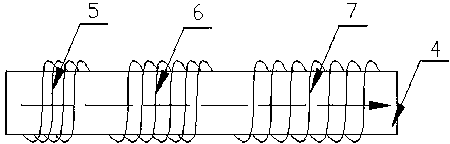

[0011] An inductor for a pipe induction heating device, consisting of a first inductor winding, a second inductor winding and a third inductor winding; the first inductor winding 5, the second inductor winding 6 and the third inductor 7 winding along The running direction of the workpiece 4 is wound on the outer surface of the workpiece 4 sequentially, wherein the number of turns of the induction heating coils of the first inductor winding 5, the second inductor winding 6 and the third inductor winding 7 are different and are in an increasing form.

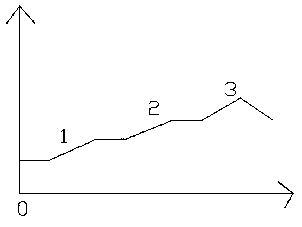

[0012] Such as image 3 , 4 As shown, since the number of turns of the first inductor winding 5 is less, the impedance is much lower than that of the second inductor winding 6 and the third inductor winding 7, so the current flowing through the first inductor winding 5 is relatively much larger , so when the workpiece 4 passes through the first inductor winding 5, it will absorb relatively more energy from the first inductor wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com