Novel textile fabric

A new type of textile fabric and technology, applied in textiles, textiles, papermaking, fabrics, etc., can solve problems such as low efficiency, and achieve the effects of enhancing heating and heat storage functions, improving evaporation efficiency, and improving drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

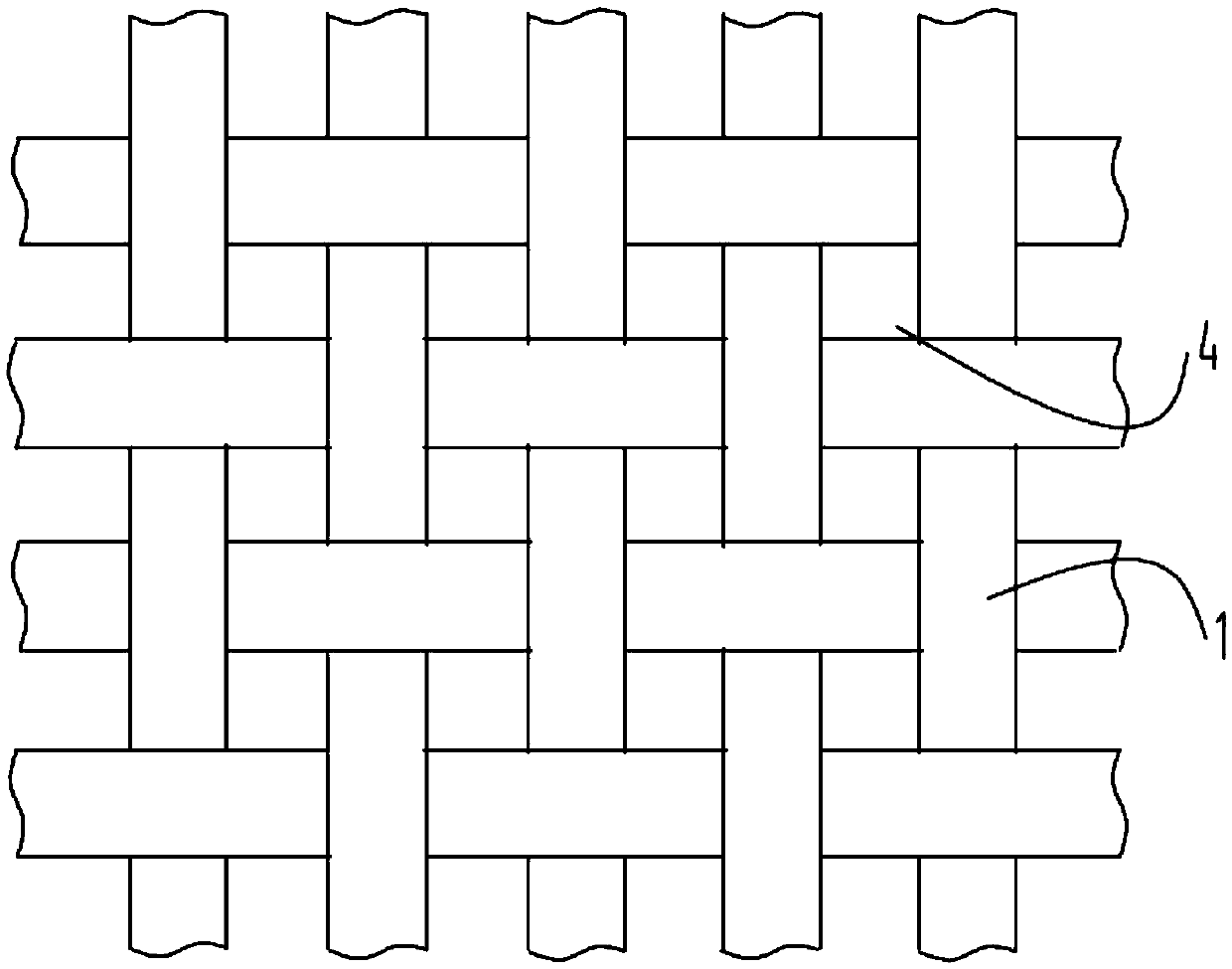

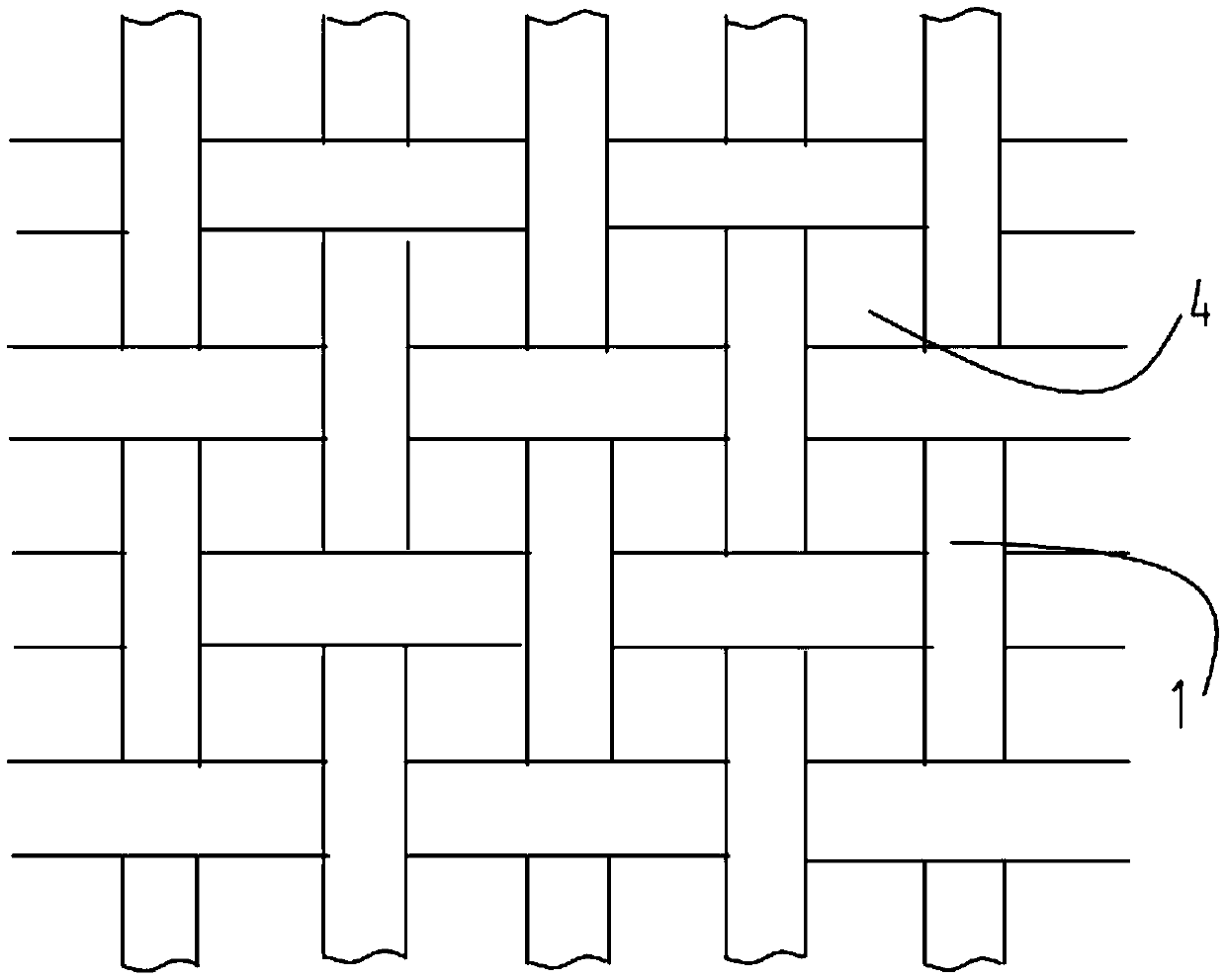

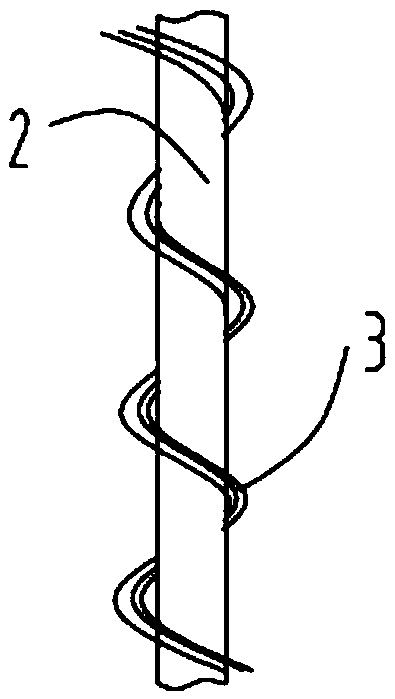

[0019] figure 1 It is a schematic diagram when the fabric is not deformed, figure 2 It is a schematic diagram of the fabric deformed by water, image 3 Schematic diagram of the structure of the core-spun yarn. like figure 1 , figure 2 and image 3 As shown, what this embodiment provides is a kind of novel textile fabric, and the yarn of described novel textile fabric is a kind of core-spun yarn 1, and yarn core part 2 is made up of a kind of functional fiber that is beneficial to dehumidification, and winding part 3 is made of A kind of functional fiber of heating and heat storage; the functional fiber of the temperature rising and heat storage is composed of 60 parts by weight of conventional fiber materials, 20 parts by weight of carbon black particles for pigments, and 20 parts by weight of carbon black particles. 20 parts of color masterbatches are formed by melt spinning; the functional fibers that are beneficial to dehumidification are formed by melt spinning with...

Embodiment 2

[0024] The difference between Example 2 and Example 1 is that: the functional fiber for heating and thermal storage is composed of 80 parts by weight of conventional fiber materials, 15 parts by weight of carbon black particles for pigments, and 15 parts by weight of carbon black particles. 5 parts of color masterbatch are melt-spun; the twist number of the core part 2 is 200T / m; the twist number of the winding part 3 is 200T / m.

Embodiment 3

[0026] The difference between Example 3 and Example 1 is that: the functional fiber for heating and thermal storage is composed of 70 parts by weight of conventional fiber materials, 18 parts by weight of carbon black particles for pigments, and 18 parts by weight of carbon black particles. 12 parts of color masterbatch are melt-spun; the twist number of the core part 2 is 150T / m; the twist number of the winding part 3 is 150T / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com