A kind of preparation method of antifouling and antibacterial composite coating

A composite coating and antifouling technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problem that the total number of colonies on the surface of interior parts exceeds the standard reference value, the effect is limited, and the total number of bacteria exceeds the standard, etc. problems, to achieve remarkable results, simple application, and wide-ranging sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

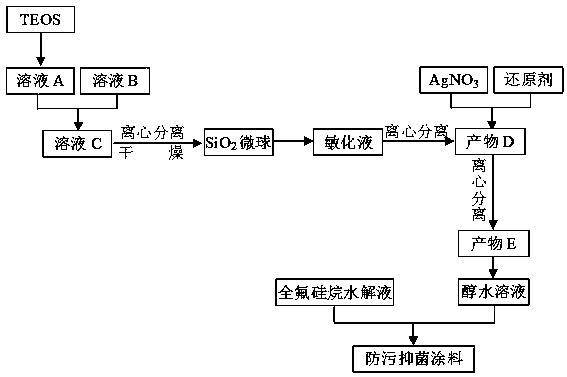

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: This embodiment provides a method for preparing an antifouling and antibacterial composite coating, comprising the following steps:

[0035](1) Disperse ethyl orthosilicate in the ethanol-distilled water mixture to obtain solution A, wherein the mass percent of orthosilicate is 1.88%, the mass percent of distilled water is 2.53%, and the balance is ethanol; Ammonia water (concentration is 28%-30%, the same below) is added to ethanol to obtain NH 3 Alcoholic ammonia solution B with a mass percentage of 6.60%; add alcoholic ammonia solution B to solution A at a rate of 20 μl / min, while stirring at 1000 rpm, and continue stirring after all alcoholic ammonia solution B is added to solution A 30 minutes, and then leave it open for 24 hours to obtain solution C, centrifuge solution C, and then dry the resulting solid product at 100°C for 3 hours to obtain SiO with a particle size of about 75nm 2 Microspheres.

[0036] (2) SnCl 2 2H 2 O is added to aqueous hy...

Embodiment 2

[0040] Embodiment 2: This embodiment provides a method for preparing an antifouling and antibacterial composite coating, comprising the following steps:

[0041] (1) Disperse ethyl orthosilicate in the ethanol-distilled water mixture to obtain solution A, wherein the mass percent of orthosilicate is 1.90%, the mass percent of distilled water is 1.63%, and the balance is ethanol; Add ammonia to ethanol to get NH 3 Alcoholic ammonia solution B with a mass percentage of 5.55%; add alcoholic ammonia solution B to solution A at a rate of 25 μl / min, while stirring at 800 rpm, and continue stirring after all alcoholic ammonia solution B is added to solution A 60 minutes, and then leave it open for 48 hours to obtain solution C, centrifuge solution C, and then dry the resulting solid product at 120°C for 1.5 hours to obtain SiO with a particle size of about 63nm 2 Microspheres.

[0042] (2) SnCl 2 2H 2 O is added to aqueous hydrochloric acid to form SnCl 2 The mass percent conten...

Embodiment 3

[0046] Embodiment 3: This embodiment provides a method for preparing an antifouling and antibacterial composite coating, comprising the following steps:

[0047] (1) Disperse ethyl orthosilicate in the ethanol-distilled water mixture to obtain solution A, wherein the mass percent of orthosilicate is 1.91%, the mass percent of distilled water is 1.03%, and the balance is ethanol; Add ammonia to ethanol to get NH 3 Alcoholic ammonia solution B with a mass percentage of 4.39%; add alcoholic ammonia solution B to solution A at a rate of 30 μl / min, while stirring at 500 rpm, and continue stirring after all alcoholic ammonia solution B is added to solution A 90 minutes, and then left open for 48 hours to obtain solution C, which was centrifuged, and then the resulting solid product was dried at 100°C for 3 hours to obtain SiO with a particle size of about 24nm 2 Microspheres.

[0048] (2) SnCl 2 2H 2 O is added to aqueous hydrochloric acid to form SnCl 2 The mass percent conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com