Inner container structure, cooking equipment and preparation method of inner container structure of cooking equipment

A technology of cooking equipment and liner, which is applied to steam cooking utensils, devices for coating liquid on the surface, household appliances, etc., can solve the problems of low heating temperature, low heating power of liner, slow heating speed, etc. performance, solve the problem of grease cleaning, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

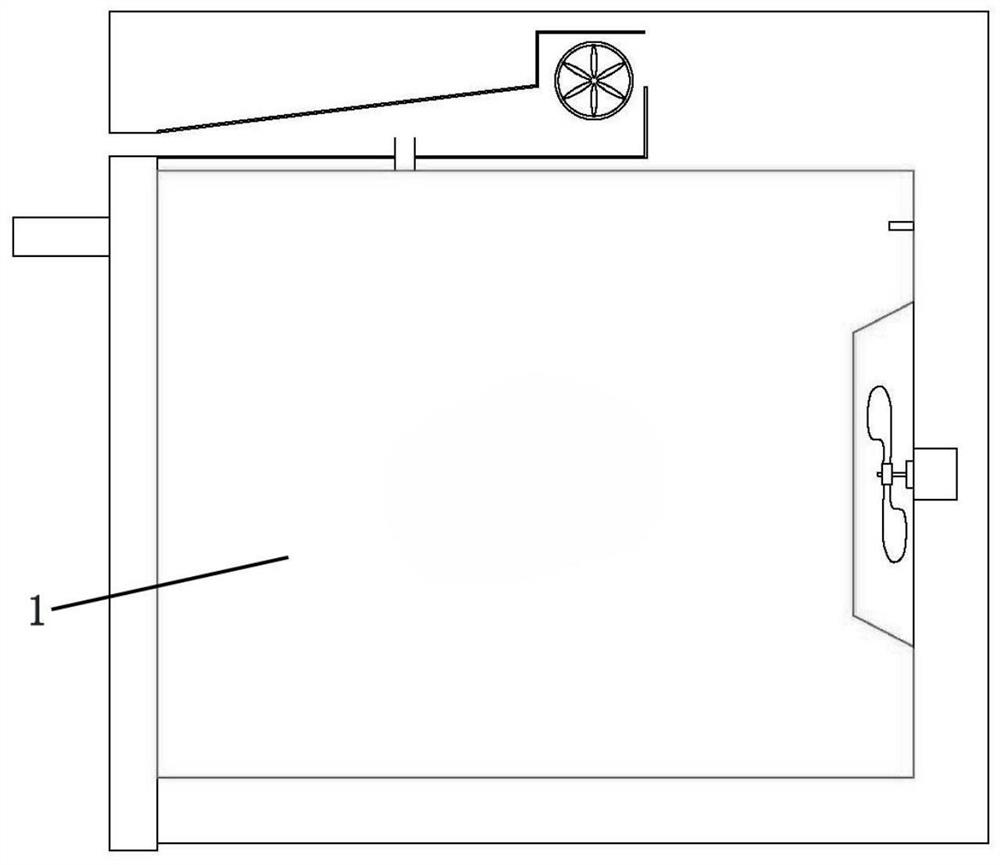

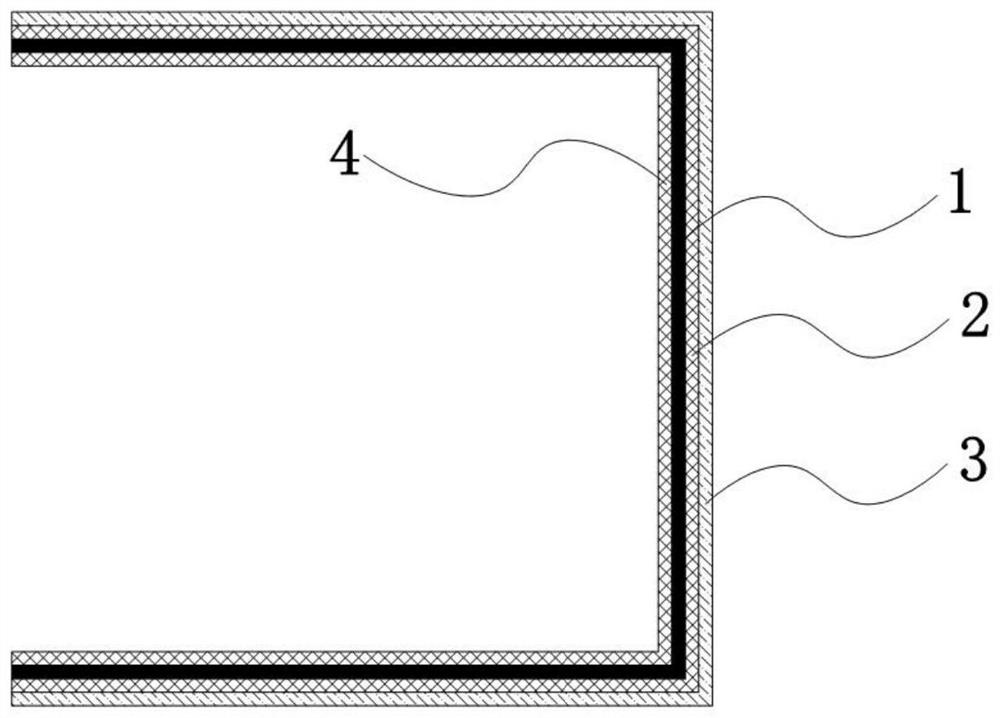

[0050] Such as figure 1 and 2 As shown, the present embodiment provides a kind of liner structure, comprises liner 1, is provided with insulating layer 2 on the outer wall of described liner 1, is provided with conductive layer 3 on the outer surface of insulating layer 2, and conductive layer 3 Infrared rays can be released under the action of voltage.

[0051] In this embodiment, the liner 1 has a cavity with an open end and the open end of the liner 1 opens forward, so that the liner 1 has an inner wall and an outer wall, and an insulating layer 2 is provided on the outer wall of the liner 1 to insulate the inner liner 1. Layer 2 is a safety measure to protect the inner tank 1 from electric shock. On the outer surface of the insulating layer 2, a conductive layer 3 is provided. The conductive layer 3 is a coating with a certain conductivity, so that the inner tank 1 The outer wall surface is provided with an insulating layer 2 and a conductive layer 3 sequentially from th...

Embodiment 2

[0060] Such as figure 1 and 2 As shown, this embodiment provides a cooking device, including the inner container structure as described in the first embodiment, the specific structure of the inner container can refer to figure 1 , which will not be repeated here. Since the cooking equipment in the second embodiment includes the inner tank structure described in the first embodiment, it has all the advantages of the inner tank structure in the first embodiment. If the structure is simple, the inner tank structure can have the advantage of rapid temperature rise , and further improve the uniformity of the temperature field of the inner tank, thereby effectively improving the cooking effect of the cooking equipment, and can also effectively solve the problems of water accumulation and grease cleaning in the inner tank after cooking, thereby improving the ease of cleaning of the inner tank.

Embodiment 3

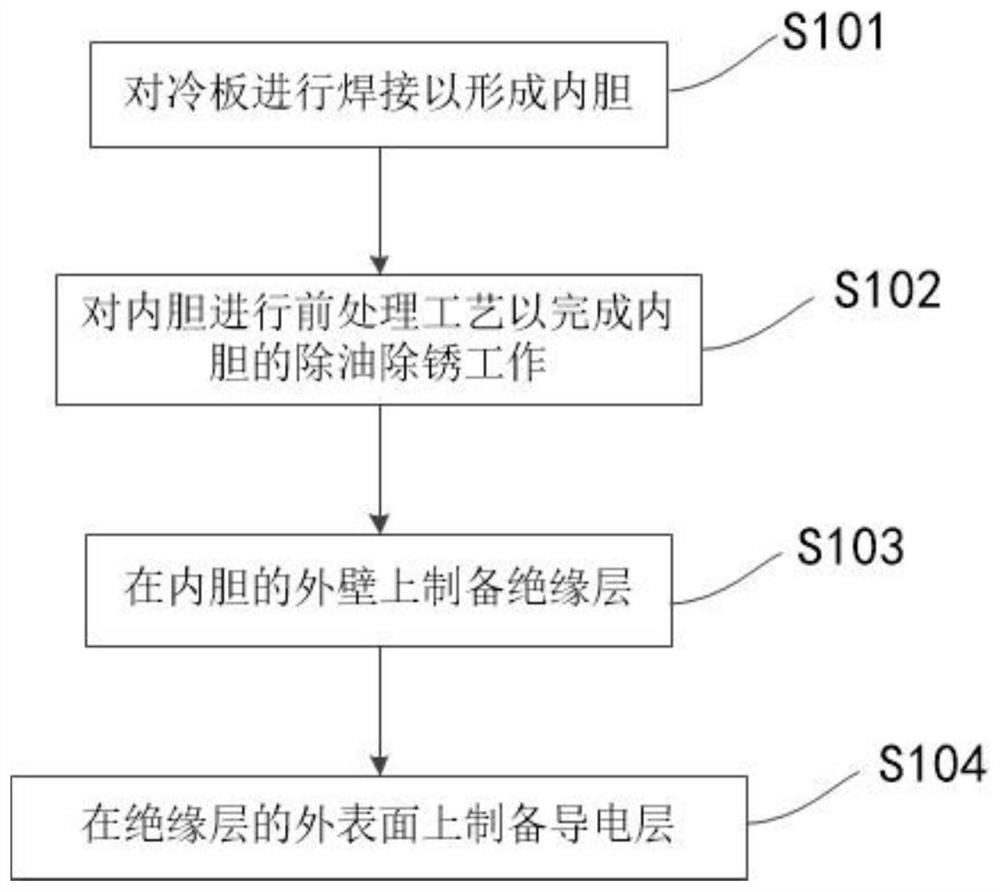

[0062] Such as Figures 3 to 5 As shown, this embodiment provides a preparation method for the inner container structure of cooking equipment, which is applied to the inner container structure as described in Example 1. For the specific structure of the inner container, please refer to figure 1 , which will not be repeated here. Since the cooking equipment in this embodiment includes the inner tank structure described in the first embodiment, it has all the advantages of the inner tank structure in the first embodiment. If the structure is simple, the inner tank structure can have the advantage of rapid temperature rise. Moreover, the uniformity of the temperature field of the inner tank is further improved, thereby effectively improving the cooking effect of the cooking equipment, and it can also efficiently solve the problems of water accumulation and grease cleaning in the inner tank after cooking, thereby improving the ease of cleaning of the inner tank.

[0063] Differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com