A kind of hydrophilic easy-to-clean coating and preparation method thereof

A hydrophilic, easy-to-clean technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as damage, affecting product appearance, and irreparable problems, and achieve good acid and alkali resistance and avoid scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

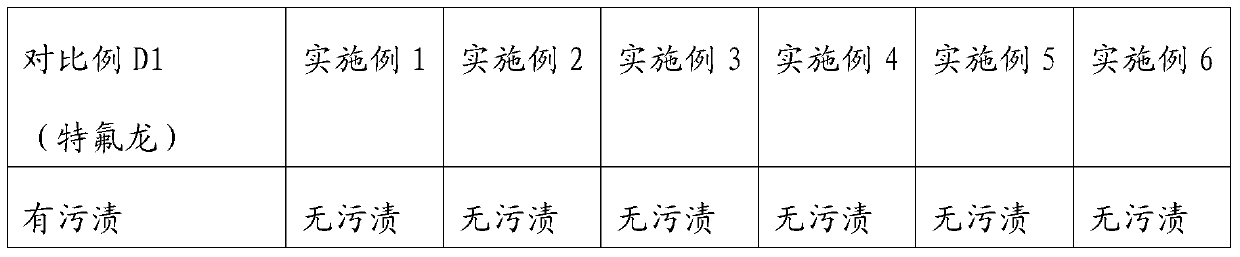

Examples

Embodiment 1

[0084] A hydrophilic and easy-to-clean paint. The components of the paint are calculated by mass percentage: 31% silica sol, 25% aluminum sol, 11% titanium sol, 6% lithium silicate aqueous solution, and hydrophilic gas phase two Silicon oxide is 6%, auxiliary agent is 1%, and solvent is 20%. The solvent includes two parts, namely: deionized water in step 1) and isopropanol in step 2).

[0085] The specific parameters of silica sol are: average particle size 8nm, SiO 2 The mass percentage is 20%, the viscosity is 20 Pa.S, the solvent is water, and the pH is 10.

[0086] The specific parameters of aluminum sol are: average particle size 10nm, Al 2 O 3 The mass percentage is 20%, the viscosity is 20 Pa.S, the solvent is water, and the pH is 4.5.

[0087] The preferred specific parameters of the titanium sol are: the average particle size is 15nm, TiO 2 The mass percentage is 20%, the viscosity is 20 Pa.S, the solvent is water, and the pH is 6.5.

[0088] The specific parameters of the l...

Embodiment 2

[0097] The preparation of a hydrophilic and easy-to-clean paint. The components of the paint are calculated by mass percentage: silica sol is 25%, aluminum sol is 30%, titanium sol is 25%, potassium silicate aqueous solution is 5%, and hydrophilic Fumed silica is 4%, additives are 0.7%, and solvents are 10.3%. The solvent includes two parts, namely: the deionized water added in step 1) and the dipropylene glycol dimethyl ether added in step 2).

[0098] The specific parameters of silica sol are: average particle size 20nm, SiO 2 The mass percentage is 35%, the viscosity is 30 Pa.S, the solvent is water, and the pH is 9.

[0099] The specific parameters of aluminum sol are: average particle size 25nm, Al 2 O 3 The mass percentage is 30%, the viscosity is 30 Pa.S, the solvent is water, and the pH is 4.

[0100] The preferred specific parameters of the titanium sol are: the average particle size is 15nm, TiO 2 The mass percentage is 30%, the viscosity is 30 Pa.S, the solvent is water, ...

Embodiment 3

[0110] Preparation of a hydrophilic and easy-to-clean paint. The components of the paint are calculated by mass percentage: 35% for silica sol, 15% for aluminum sol, 20% for titanium sol, 9% for aqueous sodium silicate solution, and hydrophilic Fumed silica is 5%, additives are 1%, and solvents are 15%. The solvent in this formula includes two parts, namely: deionized water in step 1) and ethanol in step 2).

[0111] The specific parameters of silica sol are: average particle size 12nm, SiO 2 The mass percentage is 30%, the viscosity is 25Pa.S, the solvent is water, and the pH is 11.

[0112] The specific parameters of aluminum sol are: average particle size 15nm, Al 2 O 3 The mass percentage is 25%, the viscosity is 25 Pa.S, the solvent is water, and the pH is 6.

[0113] The preferred specific parameters of the titanium sol are: the average particle size is 10nm, TiO 2 The mass percentage is 25%, the viscosity is 25 Pa.S, the solvent is water, and the pH is 7.

[0114] The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com