Device for processing hole spraying during water jet coal seam gap cutting

A processing device and water jet technology, applied in safety devices, liquid/gas jet drilling, mining equipment, etc., can solve the problem of heavy weight of the sealer and buffer device, laborious handling and installation of laborers, thickness of the wall of the sealer etc. to achieve the effects of light weight, elimination of potential safety hazards, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the drawings and specific implementation examples.

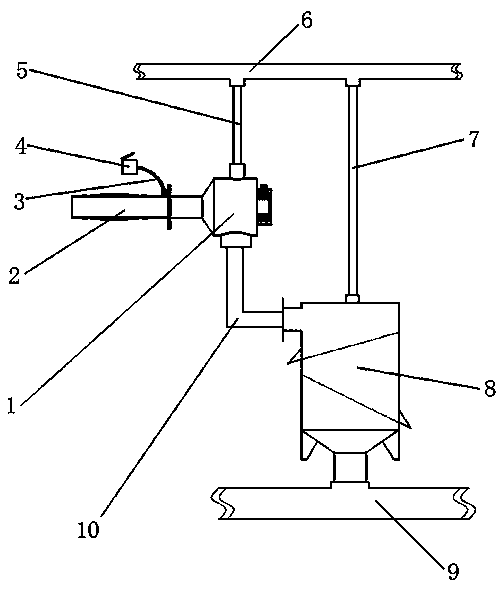

[0021] A water jet coal seam slitting nozzle hole treatment device includes a hole sealer 2, a manual valve 4 connected to the water connector 20 of the hole sealer 2 through a hose 3, and a buffer sealer with one end connected to the hole sealer 2 by bolts 1; the upper end of the buffer sealer 1 is provided with a gas hose 5 connected with the tunnel gas drainage pipe 6, and the lower end is provided with a thick hose 10 connected with the gas-water slag separation tank 8; the upper part of the gas-water slag separation tank 8 The second gas hose 7 is connected with the roadway gas drainage pipe 6, and the gas-water slag separation tank 8 is equipped with a two-stage sieve filter, and the bottom is connected with the drainage pipe 9.

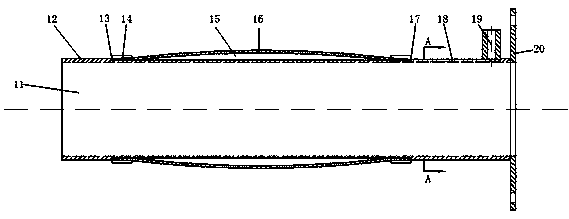

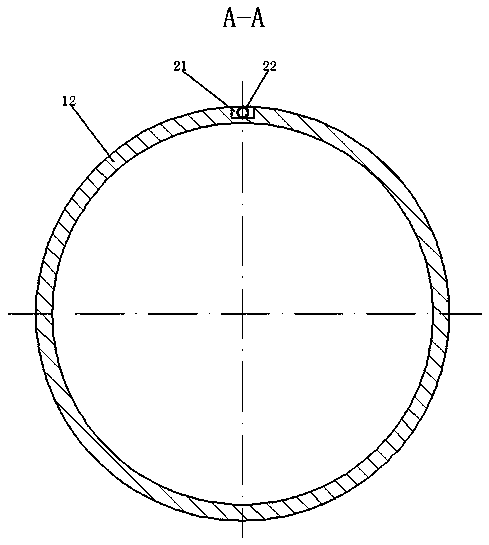

[0022] The hole sealing device 2 is provided with a hollow structure 11 to accommodate drill rods in and out, includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com