Front end support adjustable variable pitch device based on inclined hinge blade

A technology of hinged brackets and blades, which is applied in the control of wind turbines, engine functions, engines, etc., can solve the problems of complex force state and pitch change of the folding pitch drive device, and achieve simple structure, balanced force, and pitch change. way simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, structure of the present invention and specific embodiment are described further:

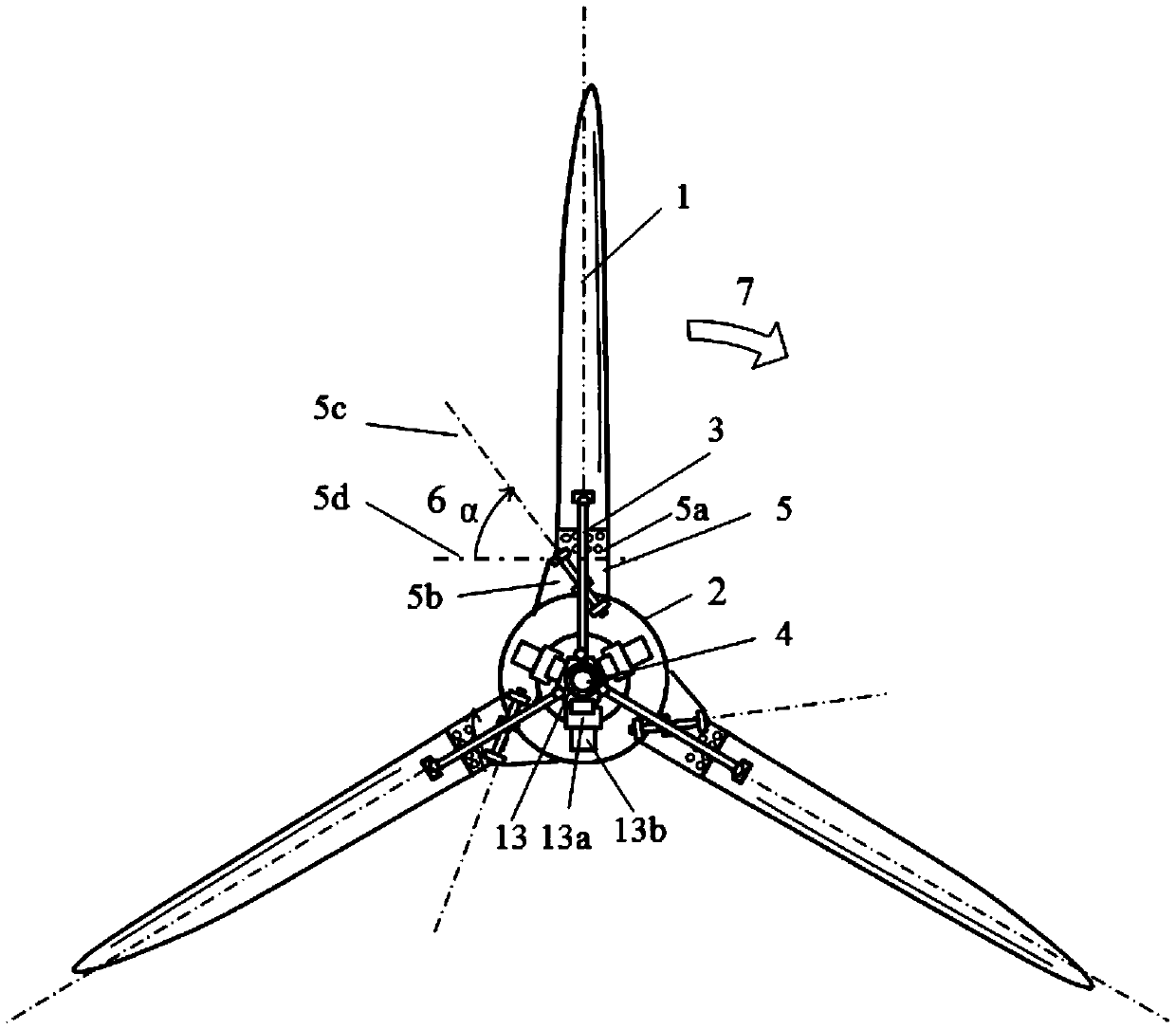

[0021] figure 1 Front view of a front-end support adjustable pitch device based on inclined hinged blades provided by the present invention, the device includes blade 1, hub 2, fan main shaft 8, inclined hinge assembly 5, front-end support connection assembly 3 and front-end pitch Adjustment assembly 4, the blade of the wind power generator device is an inclined hinged blade 1, the root of the blade is connected to the hub 2 through an inclined hinged assembly 5, and the front end support connection assembly 3 is connected to the front end pitch adjustment assembly 4 in the blade root area; The hinge axis tilt angle 6 formed by the hinge axis 5c of the blade hinge bracket 5a in the tilt hinge assembly 5 and the blade chord line 5d is between 45° and 75°.

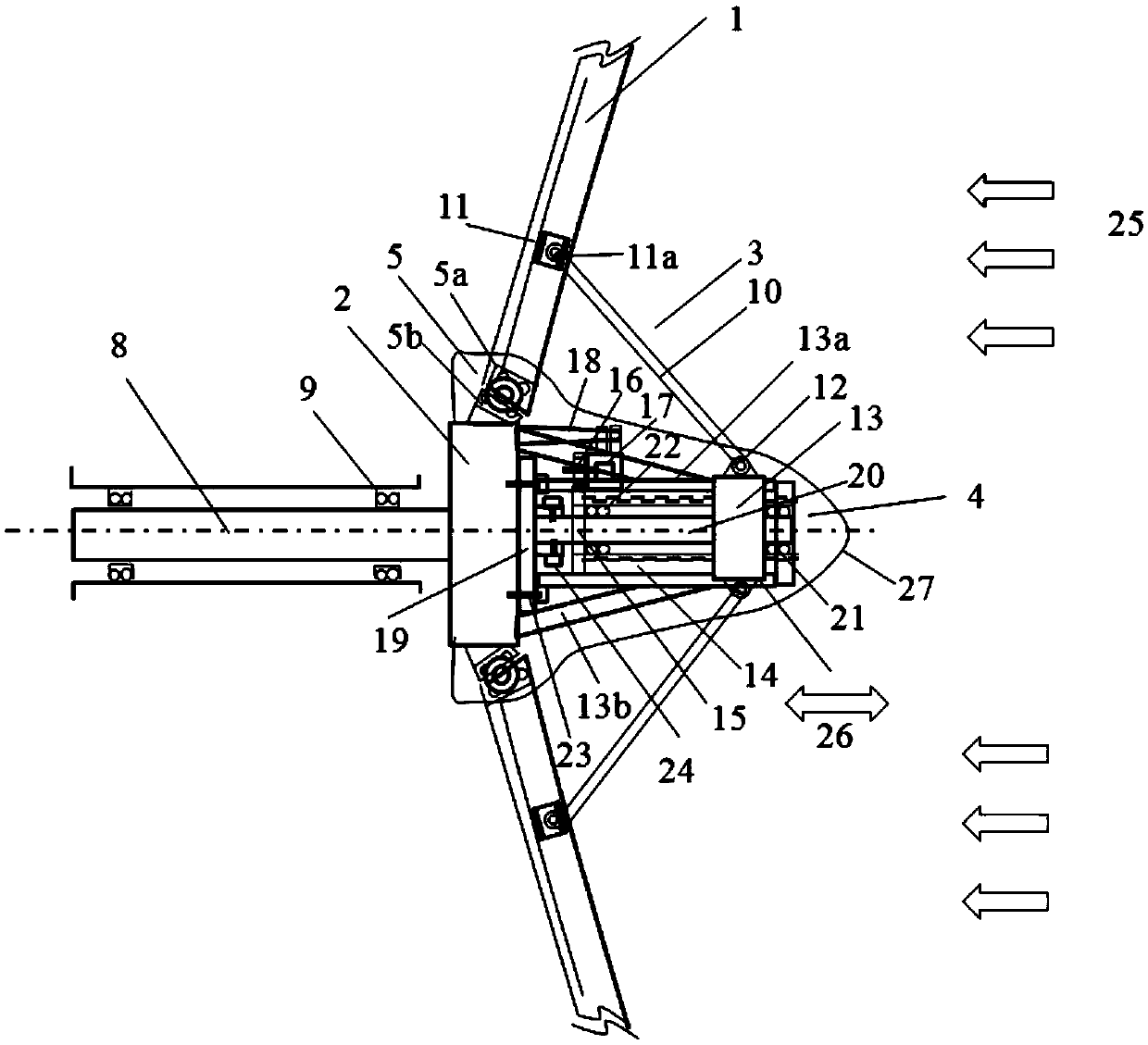

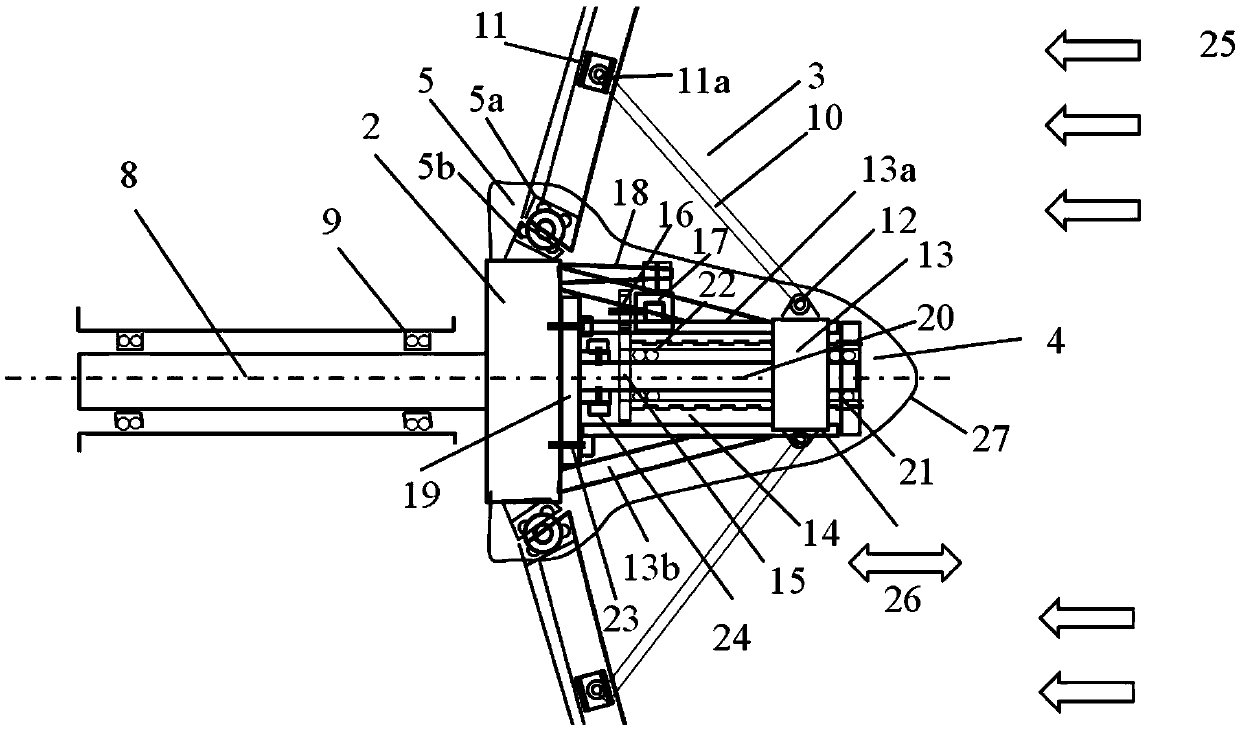

[0022] figure 2 Side view of a nose-supported adjustable pitch device based on til...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com