Method for randomly setting functions of all points of PLC

A technology of functions and function names, applied in the direction of program control, instruments, control/adjustment systems in sequence/logic controllers, etc., can solve problems such as inconvenience in use and service, increase in debugging difficulty and cost, and achieve perfect debuggable functions , convenient debugging method, and the effect of reducing work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

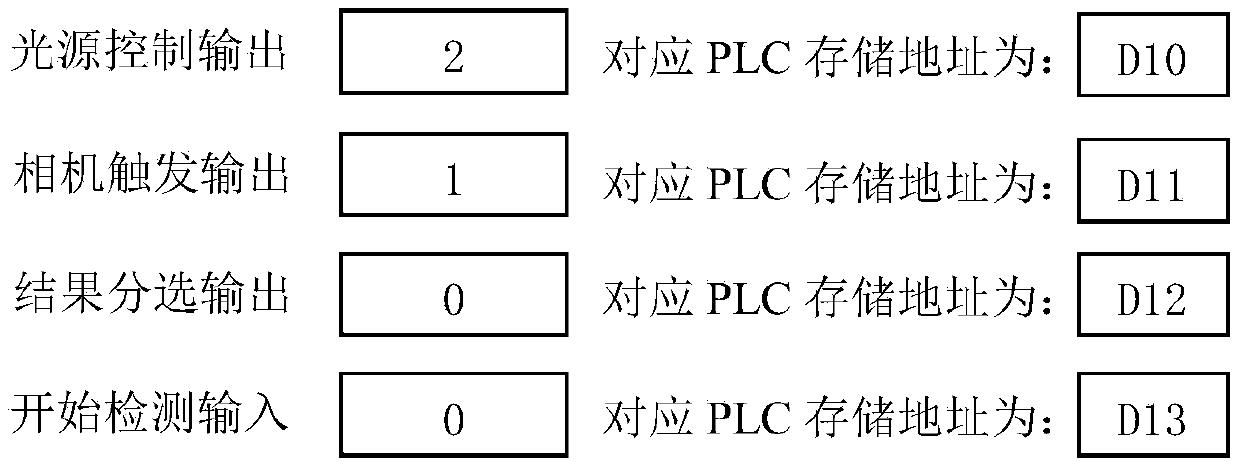

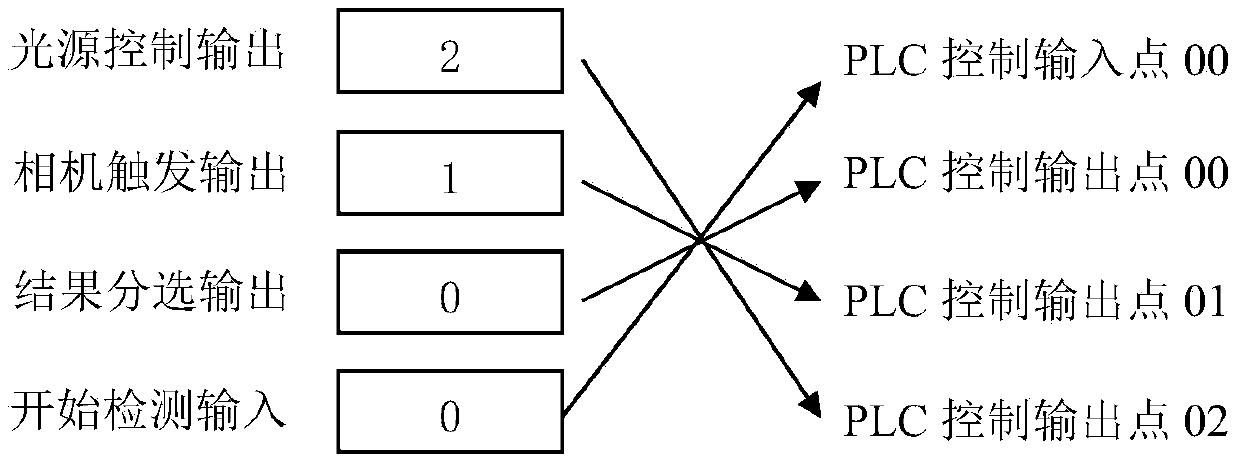

[0016] 1) if figure 1 As shown, when the debugger wants to change the input / output according to the actual needs of the customer, he can debug the data in the data frame. After the content of the debug data frame changes, the value of the corresponding PLC internal memory D10 will also change accordingly. . The guide algorithm is used inside the PLC to map the specific function points of the predetermined system to the corresponding external input / output connection points of the PLC ( figure 2 ).

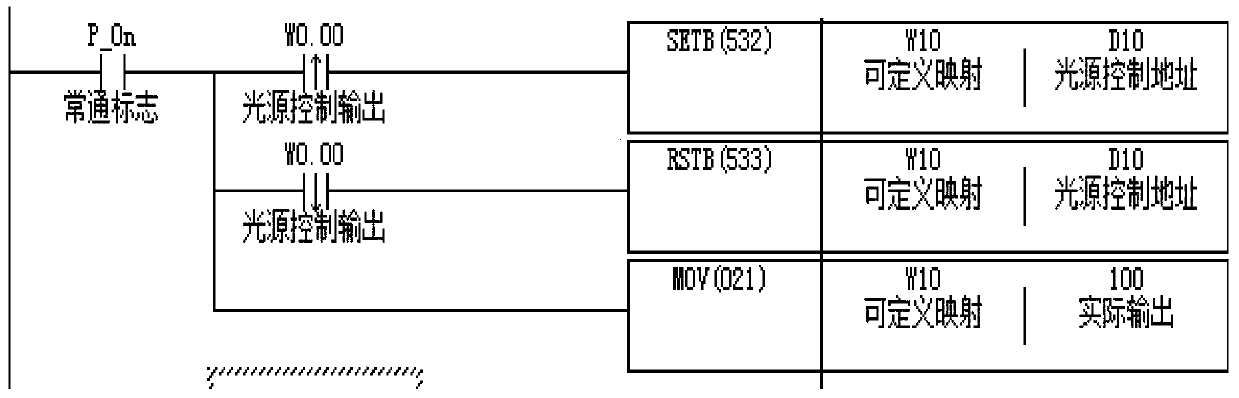

[0017] 2) When the PLC program requires a certain function point to be set ( image 3 ), the program internal register W0.00 is set to 1, the rising edge of W0.00 is valid, and the SETBW10D10 instruction is executed. The SETB command sets the bit corresponding to W10 to 1 according to the parameters in D10. Figure 4 Step 1 shows that the initial val...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap