Method for Improving Unbalanced Three-phase Power Supply in Hot Zone of Large Hot Isostatic Press

A technology of hot isostatic press and unbalanced power supply, which is applied in the direction of reducing the asymmetry of the multi-phase network and eliminating/reducing the asymmetry of the multi-phase network, which can solve the problem of affecting the energy efficiency of the power grid and the unbalanced state of the three-phase load of the power grid. The improvement of electrical components, affecting the performance and service life of electrical components, etc., to achieve the effect of eliminating voltage instability, safe and reliable structural parts, and reducing the degree of weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

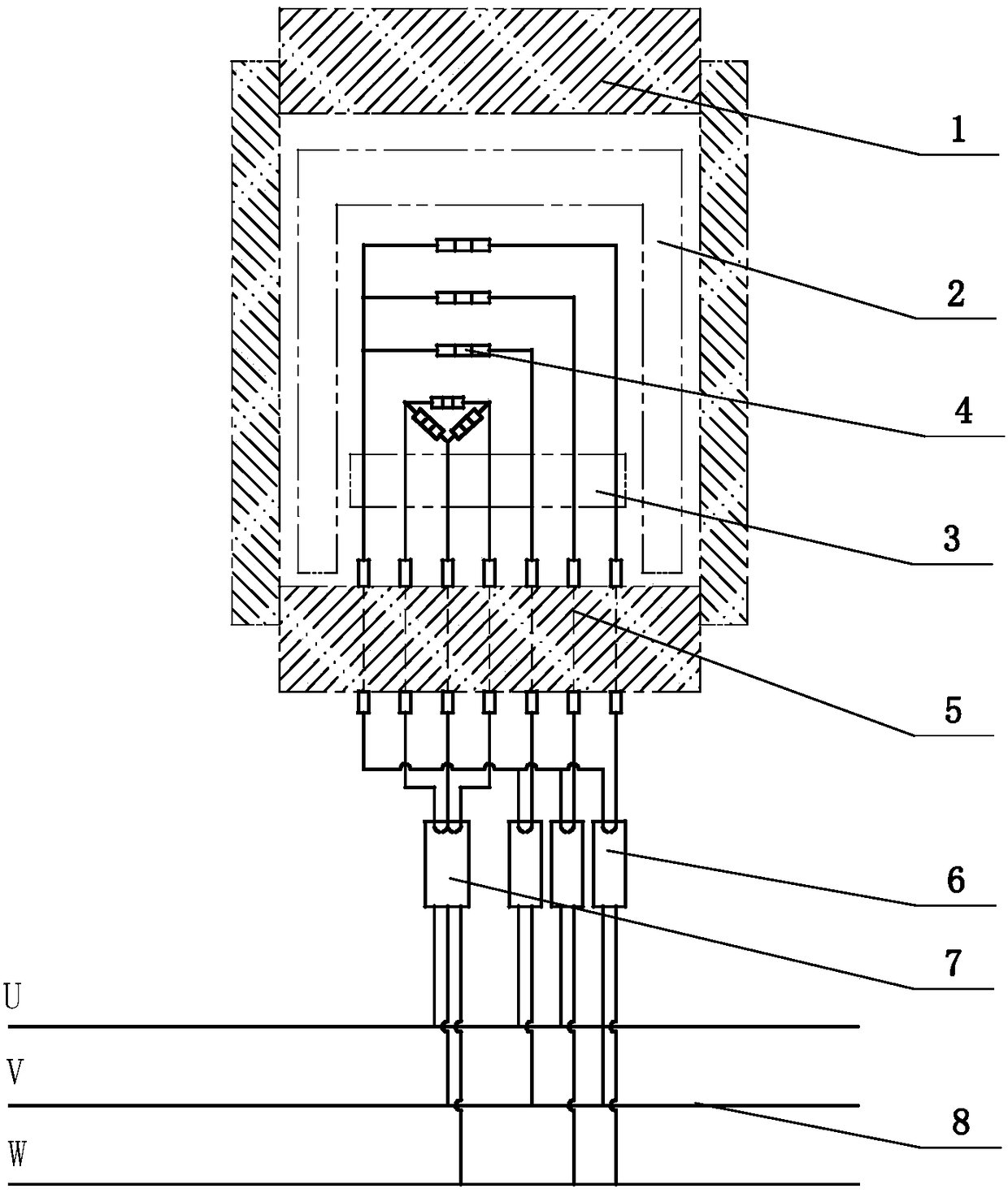

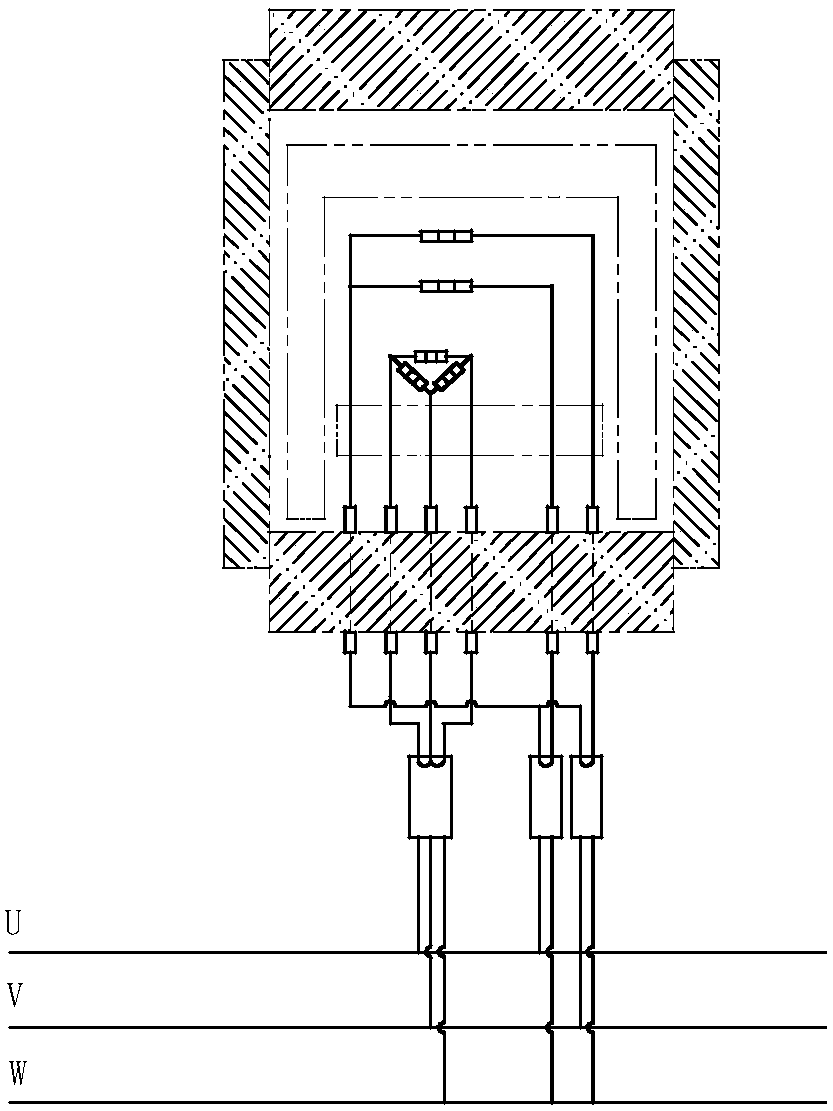

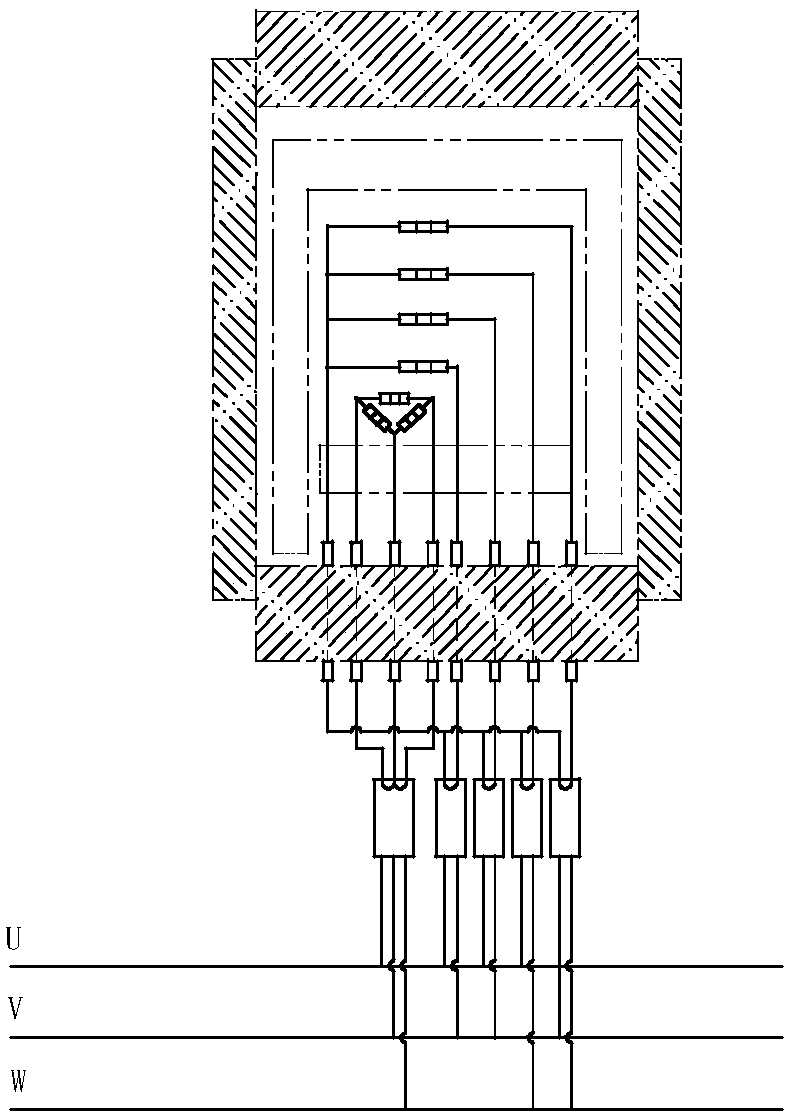

[0015] refer to figure 1 . According to the present invention, in the pressure vessel (6) of the hot isostatic press, the hot zone space formed by the heat shield 2 on the upper part and the heat insulating pad (3) on the bottom is divided into multiple hot zones according to height , set the heating element (4) around the space of the hot zone at each height; set the heating element (4) of the hot zone at the lowest height as three identical loads connected to three electrodes in a delta connection, and three identical loads Distributed around the lowermost heat zone; the heating elements (4) of the other high heat zones are all set as a single load connected to one electrode, and share another electrode, and each electrode passes through the electrode lead-out device under the pressure vessel 6 (5), leading out of the pressure vessel (6), the electrodes leading out of the pressure vessel pass through the three-phase transformer and controller 7 and multiple sets of single-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com