Hybrid excitation magnetic linkage parallel double-rotor combined motor

A hybrid excitation and composite motor technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of large thickness of the stator yoke and increase the volume of the motor, so as to improve utilization, flexibility and reliability The effect of flexibility and flexible working mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

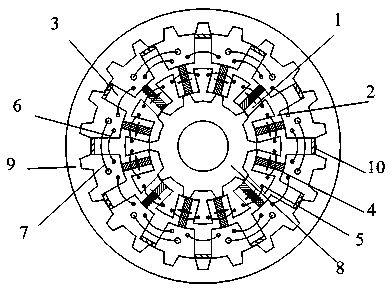

[0026] Due to the different phase numbers, the structure of the hybrid excitation flux linkage parallel dual-rotor composite motor for electric vehicles is basically the same; the following uses a three-phase electric vehicle hybrid excitation flux with 12 slots in the stator / 10 poles in the rotor and 12 slots in the outer motor stator / 22 poles in the rotor. Take chain-parallel dual-rotor compound motor as an example.

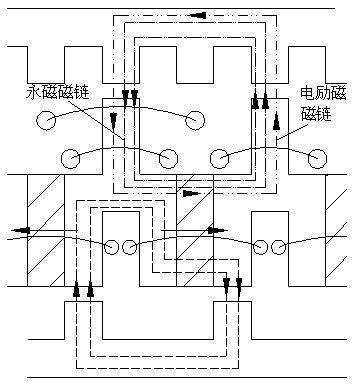

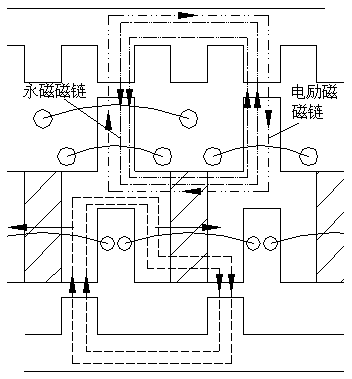

[0027] Such as figure 1 As shown, the hybrid excitation flux linkage parallel dual-rotor composite motor of the present invention includes an inner rotor 8, a stator and an outer rotor 9 arranged concentrically from the inside to the outside, and an air gap is provided between the two rotors and the stator The outer surface of the inner rotor 8 and the inner surface of the outer rotor 9 are salient pole structures, and the inner surface and the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com