Underfill material and process for producing semiconductor device using same

An underfill material and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of narrow mounting edge, achieve wide mounting edge, good solder joint performance, The effect of gap installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0071] In addition, this technology can also be applied to TSV (Through Silicon Via) technology that electrically connects a plurality of chip substrates stacked in a sandwich shape by filling metal into small holes provided in a semiconductor chip.

[0072] That is, it can also be applied to a method of manufacturing a semiconductor device in which a plurality of chip substrates having a first surface on which electrodes with solder are formed and a second surface on which a plurality of chip substrates are stacked are formed on the first surface. On the opposite side, a counter electrode opposite to the electrode with solder is formed.

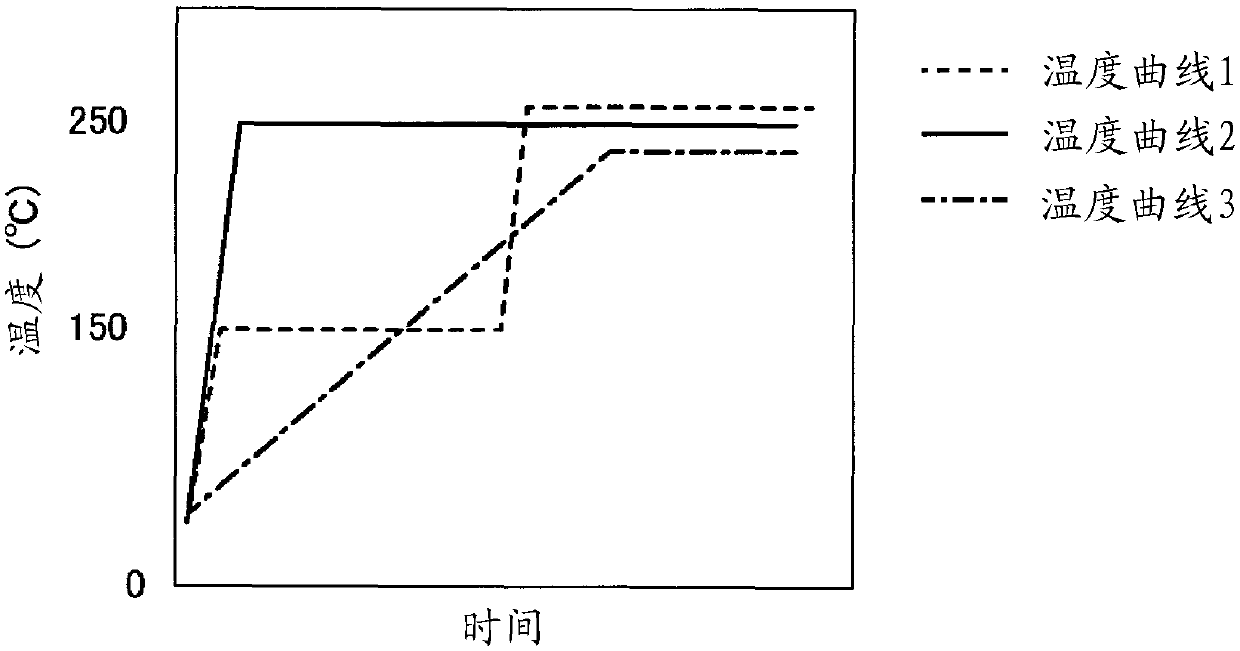

[0073] At this time, the underfill film is mounted on the second surface of the second chip substrate with the underfill film attached to the first surface side of the first chip substrate. Thereafter, by thermocompression-bonding the first surface of the first chip substrate and the second surface of the second chip substrate at a temperatu...

Embodiment

[0075]

[0076] Hereinafter, examples of the present invention will be described. In this example, a pre-feed type underfill film was produced, and the melt viscosity was measured under conditions of a temperature increase rate of 5° C. / min to 50° C. / min. Then, an IC chip having solder-attached electrodes was connected to an IC substrate having electrodes opposed thereto using an underfill film to produce a package, and voids and solder joints were evaluated. In addition, this invention is not limited to these Examples.

[0077] The measurement of the melt viscosity, the preparation of the package, the evaluation of the voids, and the evaluation of the solder joint were performed as follows.

[0078] [Measurement of Melt Viscosity]

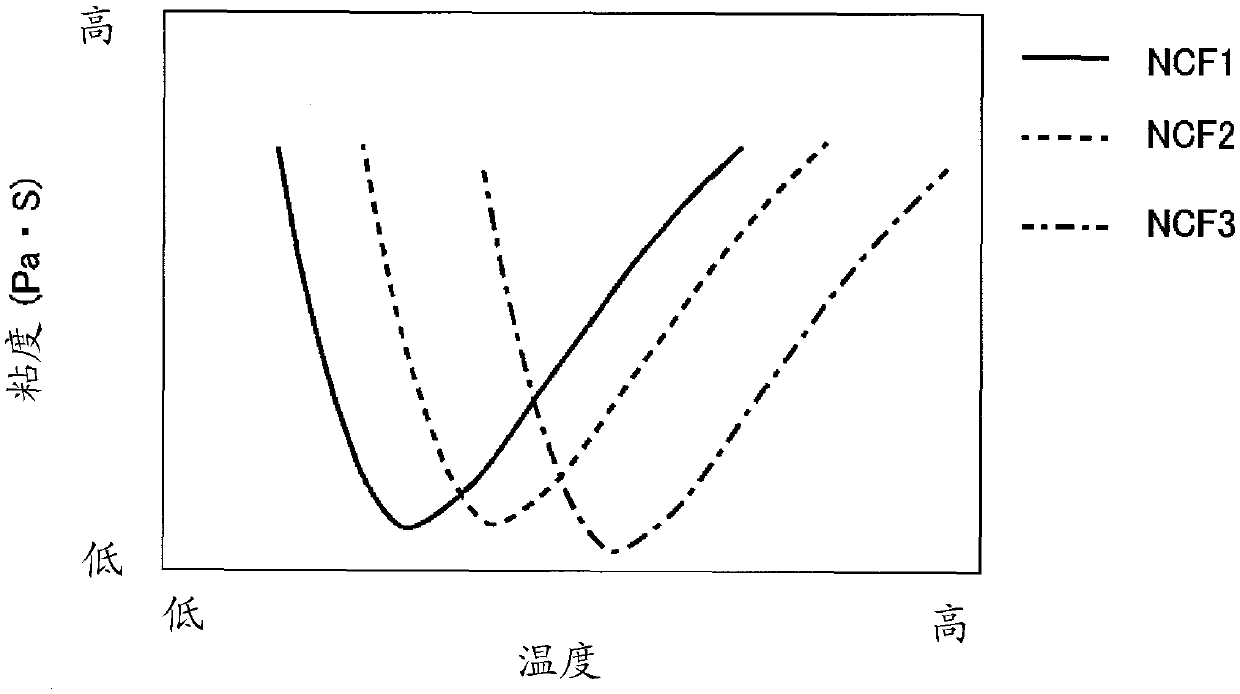

[0079] For each underfill film, using a rheometer (ARES manufactured by TA Co., Ltd.), conditions A at 5°C / min and 1 Hz, condition B at 10°C / min and 1 Hz, condition C at 20°C / min and 1 Hz, and 30 Under condition D of °C / min, 1 Hz, condition E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com