Corrosion-prevention high-temperature-resistant boosts used in high-risk chemical sites and manufacturing method therefor

A high-temperature-resistant and high-temperature-resistant ceramic technology, used in clothing, applications, footwear, etc., can solve the problems of high temperature, potential safety hazards, raw material leakage, etc., to avoid corrosion, improve corrosion resistance, and avoid wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

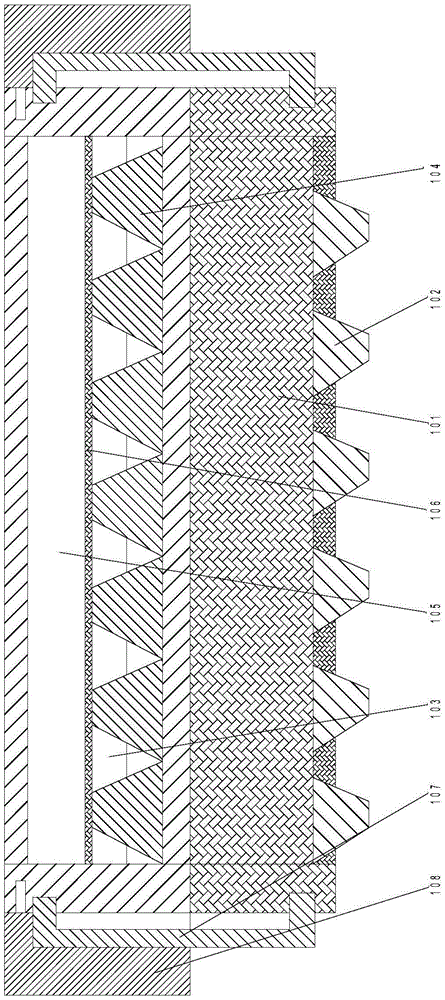

[0028] Such as figure 1 As shown, a high-risk chemical site anti-corrosion and high-temperature resistant boots, including a boot body and a sole 101 arranged under the boot body, the sole 101 is an anti-corrosion surface layer formed by cross-laying polytetrafluoroethylene fibers bonded to anti-corrosion rubber The anti-corrosion surface layer is bonded to the anti-corrosion rubber through polypropylene fiber anti-corrosion glue, and flange structures 102 made of ceramics arranged at equal intervals are arranged on the lower end surface of the sole 101. The flange structure 102 runs through the anti-corrosion surface layer and the polypropylene fiber anti-corrosion glue and is fixedly connected to the anti-corrosion rubber. On the side of the boot body facing the sole 101, a The cavity 103 is provided with massage protrusions 104 arranged at equal intervals in the cavity 103. The free ends of the massage protrusions 104 face the upper end of the boot body, and the adjacent ma...

Embodiment 2

[0034] On the basis of Example 1, this embodiment also discloses a method for manufacturing high-risk chemical site anti-corrosion and high-temperature resistant boots, which is characterized in that it includes the following steps:

[0035]S1: Making the sole structure, including the following steps:

[0036] S1.1: Set a blind hole structure on the lower end surface of the anticorrosion rubber, and bond the flange structure 102 in the blind hole structure with a high temperature resistant adhesive;

[0037] S1.2: Spray polypropylene fiber anti-corrosion glue on the lower end surface of the anti-corrosion rubber, and bond the anti-corrosion surface layer on the polypropylene fiber anti-corrosion glue to make it firmly bonded;

[0038] S2: Making the boot body structure, including the following steps:

[0039] S2.1: Processing the boot body, bonding the airbag 105 under the bottom, and bonding the metal mesh layer 106 on the lower end surface of the airbag 105;

[0040] S2.2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com