Shoe sole bonding pretreatment method

A bonding and bonding surface technology, applied in footwear, shoemaking machinery, clothing, etc., can solve the problems of high VOC emissions, high energy consumption, and affecting the health of on-site workers, so as to improve the bonding strength and ensure The effect of bond quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

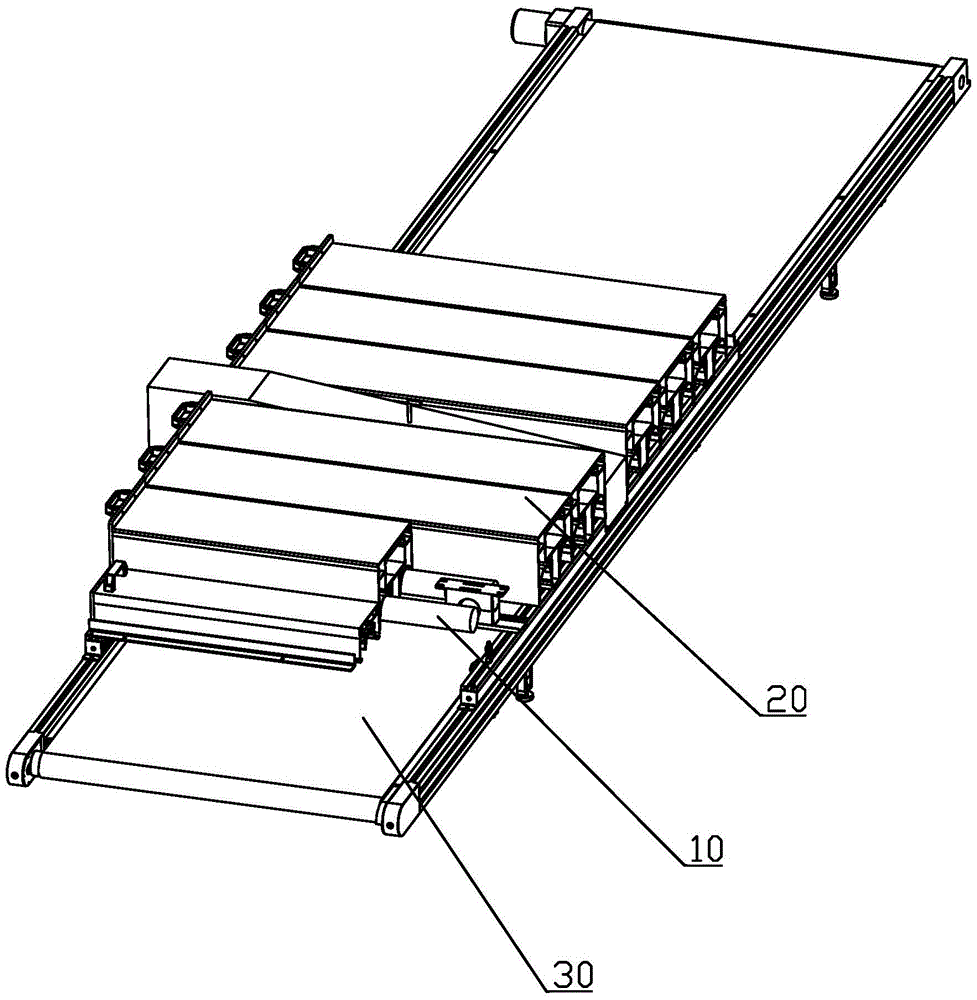

[0019] refer to figure 1 , a pretreatment method for shoe sole bonding, comprising irradiating the adhesive surface of the sole with short-wave ultraviolet light with a wavelength of 185 nm to produce a polar polymer compound on the adhesive surface of the sole, and simultaneously utilizing the short-wave ultraviolet light to irradiate the air The ozone generated during the process removes organic dirt on the bonding surface of the sole. In the present invention, the short-wave ultraviolet light with a wavelength of 185nm can break bonds on the polymer compound on the bonding surface of the shoe sole, so that the bonding surface of the shoe sole generates a polar polymer compound, achieving the same technology as physical grinding or chemical corrosion effect, so that the adhesive surface of the sole can be effectively linked with the glue, and the bonding strength of the sole can be improved. On the other hand, the short-wave ultraviolet light of this wavelength can convert t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com