A preparation process of high-strength marine steel

A preparation process and high-strength technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of inability to produce large-sized rolled pieces, difficult division of the next process, and inability to realize the common use of billets. Small bending deformation, meet the needs of large-scale high-speed production and output, and the effect of easy division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The concrete steps of present embodiment production technology are as follows:

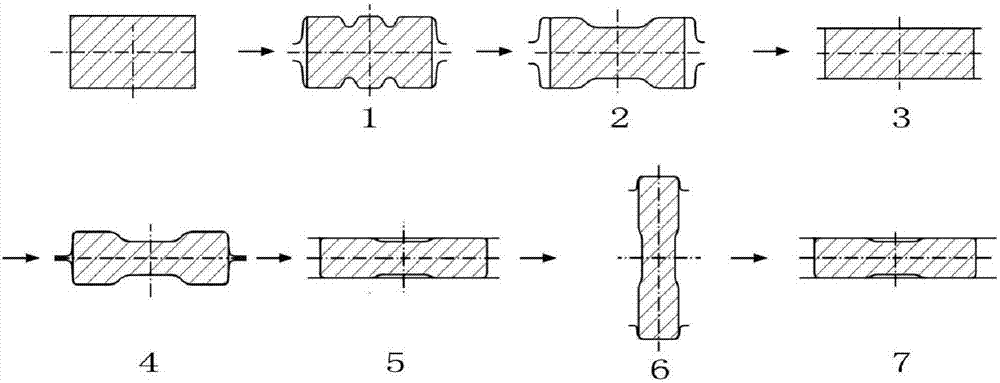

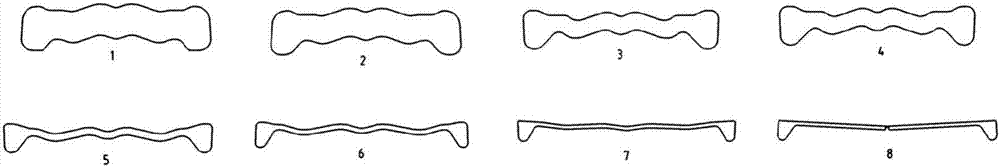

[0025] (1) Rolling by the first blanking machine (BD1): After the rectangular billet is heated, the rectangular billet is widened into a flat billet by BD1. The widening process is to first press the groove on the slab, and then press the groove The side bosses are flattened. Through partition rolling, the extension of the rolled piece is reduced and the width is increased, so that the amount of width is 30% more than that of conventional width, and at the same time, the slab can be fully widened with a small force, suitable for width Large format slabs. Such as figure 1 As shown, the rolling of BD1 in this embodiment specifically includes 7 passes: in the 1st pass, two grooves are respectively pressed out on the upper and lower sides of the slab; in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com