A two-station radial horizontal CNC ring rolling machine

A two-station, ring rolling machine technology, used in metal rolling and other directions, can solve the problems of poor control of ring size, easy deviation of the center of the ring, and unfavorable business income, saving time for loading and unloading materials, and preventing rolling failure. The effect of uniform and reduced metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

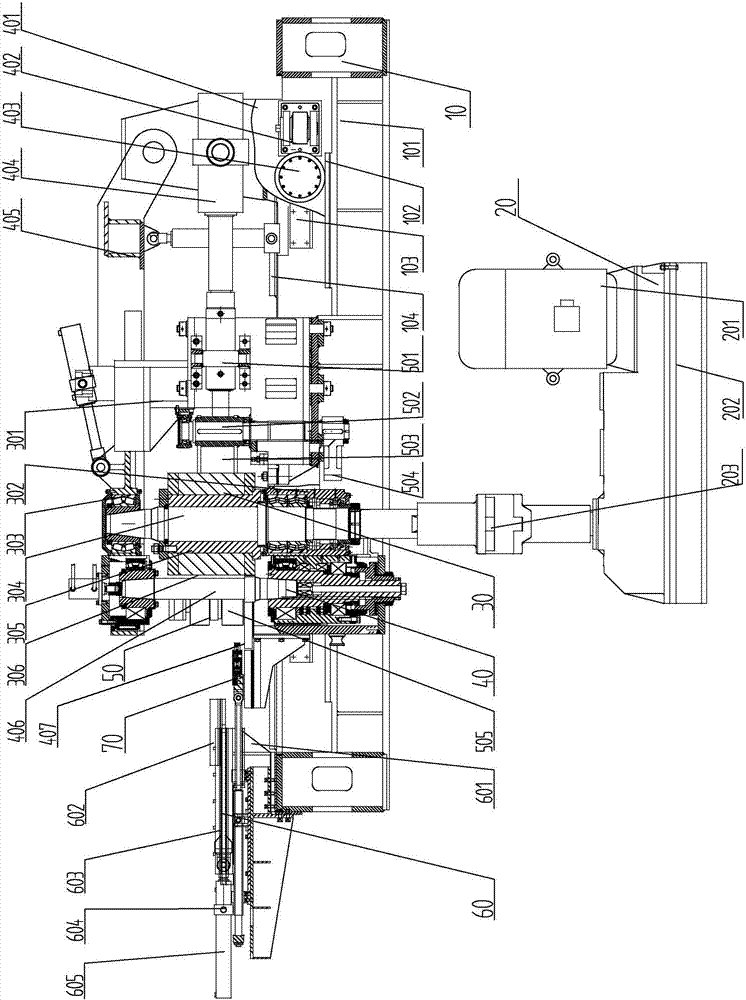

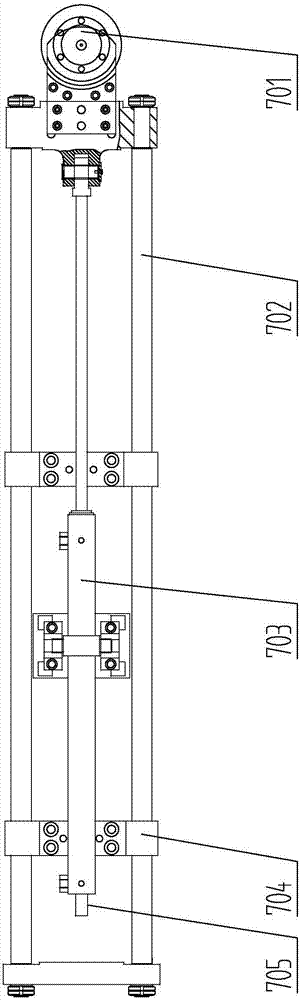

[0017] Such as figure 1 figure 2 As shown, a two-station radial horizontal CNC ring rolling machine includes a body part 10, a main transmission part 20, a main roller part 30, a radial rolling part 40, a centering part 50, and an upper support plate part 60. The measuring part 70 is composed of a hydraulic system and an electric control system. The fuselage part 10 is composed of a bed welded part 101, a guide rail plate 102, a side guide rail plate 103 and a pressure plate 104. The bed welded parts 101 are respectively welded on the machine At both ends of the body, rail plates 102 are respectively provided on both sides of the bottom of the body slide rail, side rail plates 103 are respectively provided on both sides of the body slide rail, and a pressure plate 104 is provided on the upper surface of the body slide rail;

[0018] The main transmission part 20 is made up of a main motor 201, a speed reducer 202 and a coupling 203, the main motor 201 is arranged on the spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com