TMCP high-strength steel plate for large storage tank tank wall and its manufacturing method and tank wall structure

A large-scale storage tank and high-strength steel plate technology, which is applied in the field of TMCP high-strength steel plate for large-scale storage tank walls and its manufacturing and tank wall structure, can solve the problems of prolonging the manufacturing cycle and increasing the manufacturing cost of storage tanks, and achieve weight reduction and reduction The effect of reducing the amount of materials used and the number of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

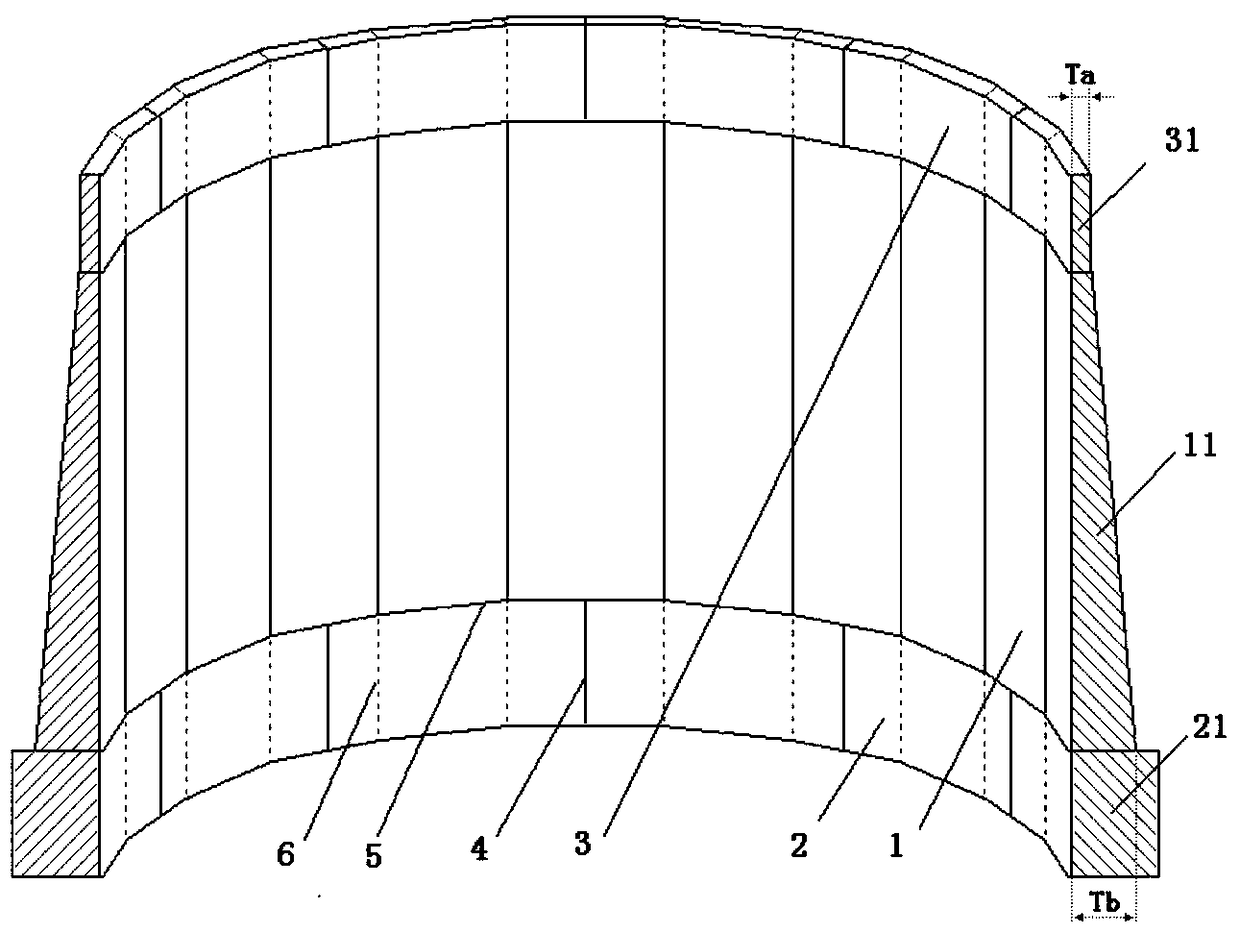

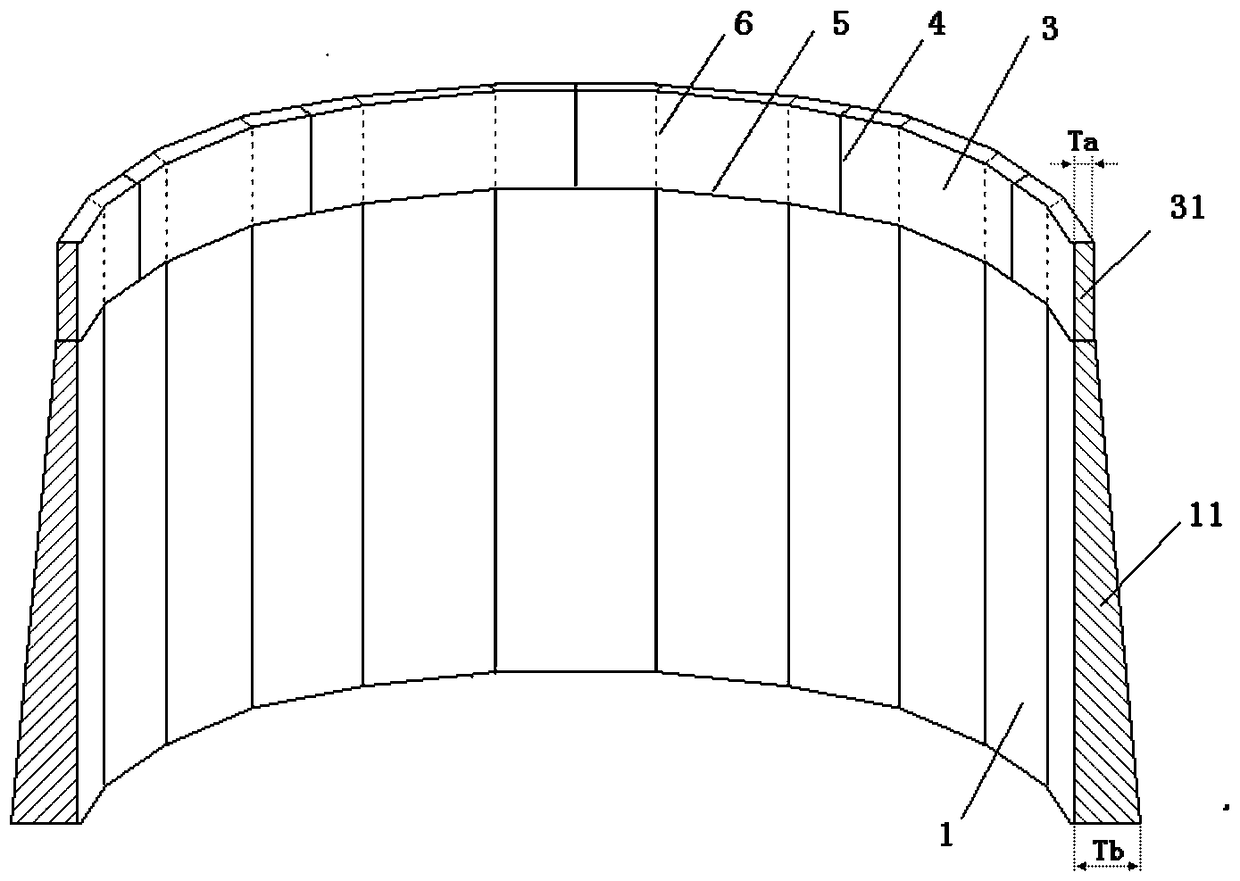

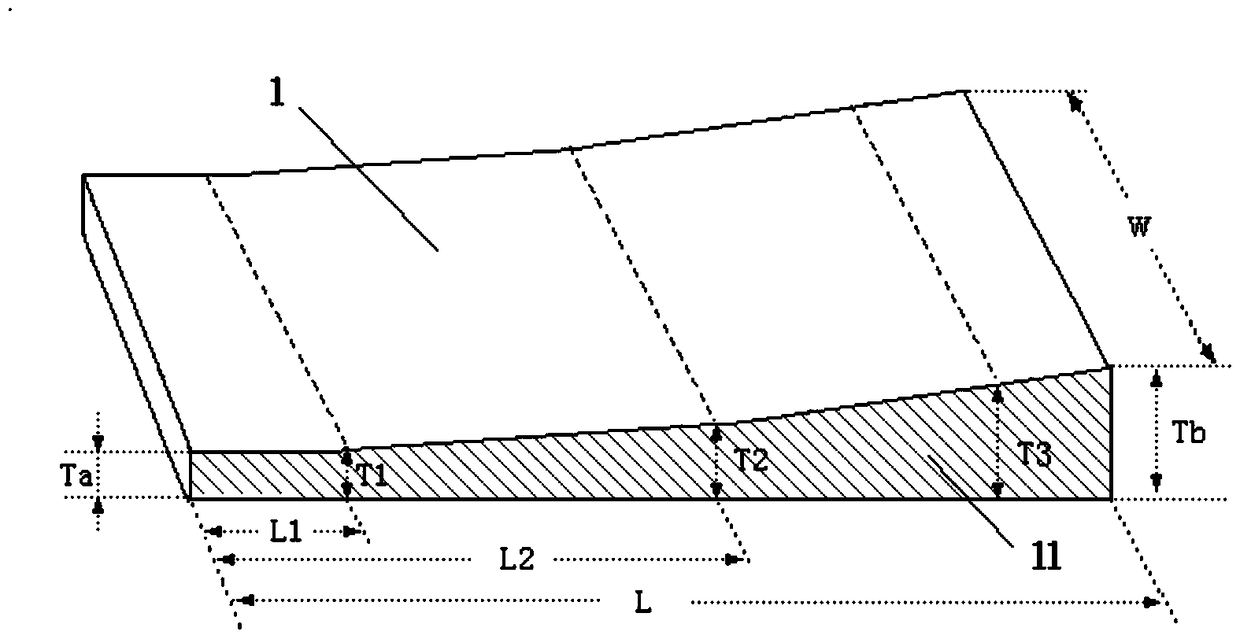

[0063] In this embodiment, a petroleum tank wall structure with a theoretical capacity of 100,000 cubic meters and steel plates for the tank wall are designed.

[0064] In the existing traditional design, the tank wall structure of such an oil storage tank with a design capacity of 100,000 cubic meters should be as follows: Image 6 shown. In the figure, 2 is a schematic diagram of the steel plate for the tank wall, and 21, 22, 23, 24, 25, 26, 27, 28 and 29 are the first layer, the second layer, and the third layer of the tank wall from top to bottom. , 4th, 5th, 6th, 7th, 8th, and 9th-layer steel plate thickness profiles. The wall of this traditional 100,000 cubic meter oil storage tank is circular, with a circumference of 252 meters, a tank wall height of 21.96 meters, and a limit oil level of 20.5 meters; A 2440mm wide × 12600mm long steel plate is welded with the plate width as the height and the plate length as the arc length. From top to bottom, the first and second l...

Embodiment 2

[0088] In this embodiment, a petroleum storage tank wall structure and steel plates for the tank wall with a theoretical capacity of 150,000 cubic meters are designed.

[0089] In the existing traditional design, the tank wall structure of such an oil storage tank with a design capacity of 150,000 cubic meters should be as follows: Figure 7 shown. In the figure, 2 is a schematic diagram of the plate surface of the steel plate used for the tank wall. The tank wall is divided into 7 layers. Schematic diagram of the thickness profile of the 3rd, 4th, 5th, 6th and 7th layer steel plates. The wall of this traditional 150,000 cubic meter oil storage tank is circular, with a circumference of 315 meters, a tank wall height of 20 meters, and a limit oil level of 19 meters; the first to sixth floors from top to bottom are 2800mm high, and the The height of the 7 floors (that is, the bottom layer) is 3200mm, and each layer is welded by 25 steel plates with a length of 12600mm, with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com