Rope winding type elevator adopting closed-loop counterweight-free drag system

A traction system and no counterweight technology, applied in the field of elevators, can solve the problems of unsecured passenger safety, serious energy loss, and short elevator life, and achieve the effects of simple structure, improved service life, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

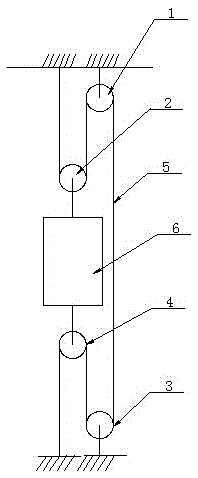

[0016] see as figure 1 As shown, the specific embodiment adopts the following technical scheme: it includes the first pulley 1, the second pulley 2, the third pulley 3, the fourth pulley 4, the steel wire rope 5, and the car 6; one end of the steel wire rope 5 hangs On the upper crossbeam, the other end of the wire rope 5 is fixed on the lower crossbeam around the second pulley 2, the first pulley 1, the third pulley 3, and the fourth pulley 4 in turn; the second pulley 2 and the upper end of the car 6 Fixed, the fourth pulley 4 is fixed to the lower end of the car 6; the first pulley 1 is fixed to the top wall, and the third pulley 3 is fixed to the ground at the bottom; the first pulley 1 is driven by a traction machine.

[0017] During the operation of this specific embodiment, the traction machine drives the first pulley 1 to rotate counterclockwise, the second pulley 2 and the fourth pulley 4 rotate clockwise, and the car 6 descends; the traction machine drives the first ...

specific Embodiment approach 2

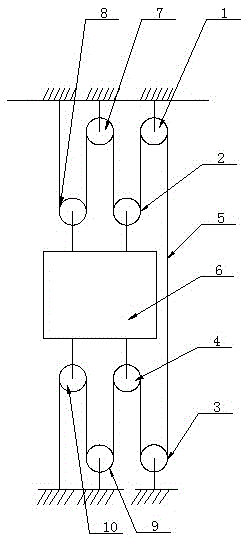

[0018] see figure 2 As shown, the difference between this specific embodiment and the first specific embodiment is that it also includes a fifth pulley 7, a sixth pulley 8, a seventh pulley 9, and an eighth pulley 10; On the upper beam, the other end of the wire rope 5 goes around the sixth pulley 8, the fifth pulley 7, the second pulley 2, the first pulley 1, the third pulley 3, the fourth pulley 4, the seventh pulley 9, the eighth pulley The pulley 10 is fixed on the lower beam; the second pulley 2, the sixth pulley 8 are fixed to the upper end of the car 6, the fourth pulley 4, the eighth pulley 10 are fixed to the lower end of the car 6; the first pulley 1. The fifth pulley 7 is fixed to the top wall, and the third pulley 3 and the seventh pulley 9 are fixed to the ground at the bottom.

[0019] This specific embodiment is applied to elevators with large loads such as freight elevators.

[0020] Preferably, the steel wire rope is replaced by a steel belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com