Reverse-flow-free nanofiltration apparatus or reverse osmosis apparatus and shutdown method thereof

A reverse osmosis device and reverse flow technology, applied in reverse osmosis, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve the problem of reducing the service life of nanofiltration devices or reverse osmosis devices, nanofiltration membranes/reverse Problems such as physical damage to the permeable membrane, wrinkling and damage on the surface of the NF/RO membrane, to achieve the effect of ensuring the desalination performance and system stability, eliminating the damage to the membrane by chemical substances, and increasing the effective desalination life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

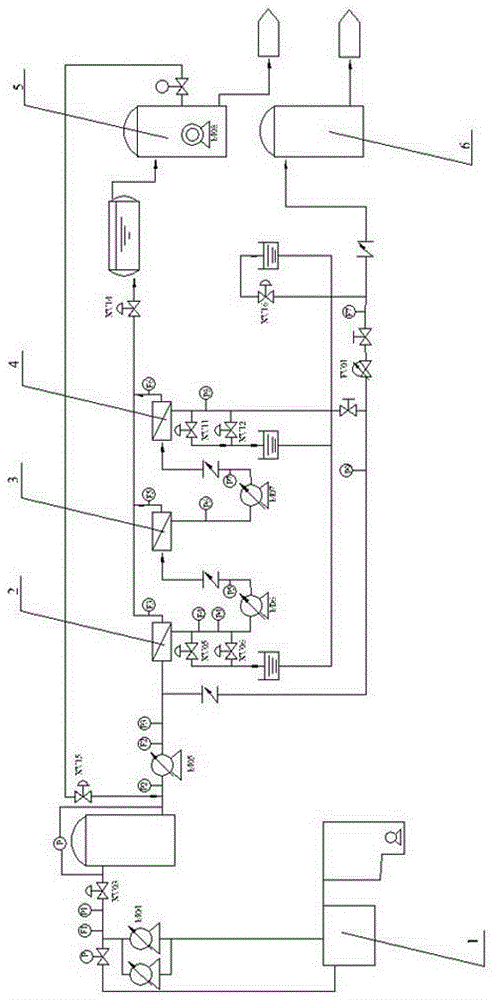

Embodiment 1

[0024] A kind of non-reverse flow nanofiltration device or reverse osmosis device according to the present invention includes a regulating tank 1 and a filter membrane unit connected thereto. There are three filter membrane units, which are respectively the first filter membrane unit 2 and the second filter membrane unit. Membrane filter unit 3 and the third membrane filter unit 4, each filter membrane unit is provided with a water inlet and two water outlets, one of which is the concentrated water outlet, and the other is the product water outlet, each filter membrane unit The concentrated water outlets are all connected to the water inlet of the next membrane filter unit, and the water outlets of the first membrane unit 2, the second membrane unit 3 and the third membrane unit 4 are connected in series to each other and then connected to the water tank 5; The water production tank 5 is also provided with two drains, one of which is connected to the water inlet of the first me...

Embodiment 2

[0027]This embodiment is basically the same as Embodiment 1, except that this embodiment adds a drain port on the concentrated water tank 6, which is connected to the water inlet of the first filter membrane unit 2, and the drain port is also The regulating valve FV01 is provided in turn, and the regulating valve FV01 is linked with the flowmeter F4. During the shutdown operation, the flow rate of the concentrated water outlet in the first membrane unit 2 can be effectively controlled by regulating the flowmeter F4 and the regulating valve. Further The amount of water in the first membrane unit 2 is controlled, which not only reduces the supply of water at the water inlet of the first membrane unit 2, but also further reduces and avoids damage to the inner membrane in the membrane unit.

Embodiment 3

[0029] This embodiment is basically the same as Embodiment 1 or 2, except that the method for controlling the shutdown of the nanofiltration device or reverse osmosis device described in this embodiment includes the following shutdown steps: (1) Start the flushing water pump M08, and close the water inlet valve XV15, after the water in the production water tank 5 is suppressed to 0.5MP on the pipeline, the constant pressure return valve DYV02 is opened; (2) Open the water inlet valve XV15, close the nanofiltration water inlet valve XV03, connect the high pressure pump M05 with the flowmeter F2 linkage control, high pressure pump M05 controls the flow meter F2 at 54m 3 / h; interlocking control between regulating valve F01V and flowmeter F4, flowmeter F4 is controlled at 42m 3 / h, the whole process is delayed for 60s; (3) The high-pressure pump M05 is adjusted by frequency conversion, and the chain control of the flowmeter F2 is transferred to the constant pressure control with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com