Diesel oil and method for producing diesel oil

A technology for diesel oil and low-quality feedstock oil, applied in the petroleum industry, processing hydrocarbon oil, liquid carbon-containing fuel, etc., can solve the problems of small density reduction, high sulfur content, small cetane number increase, etc., and achieve the cost of transformation Low height, improved switching operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

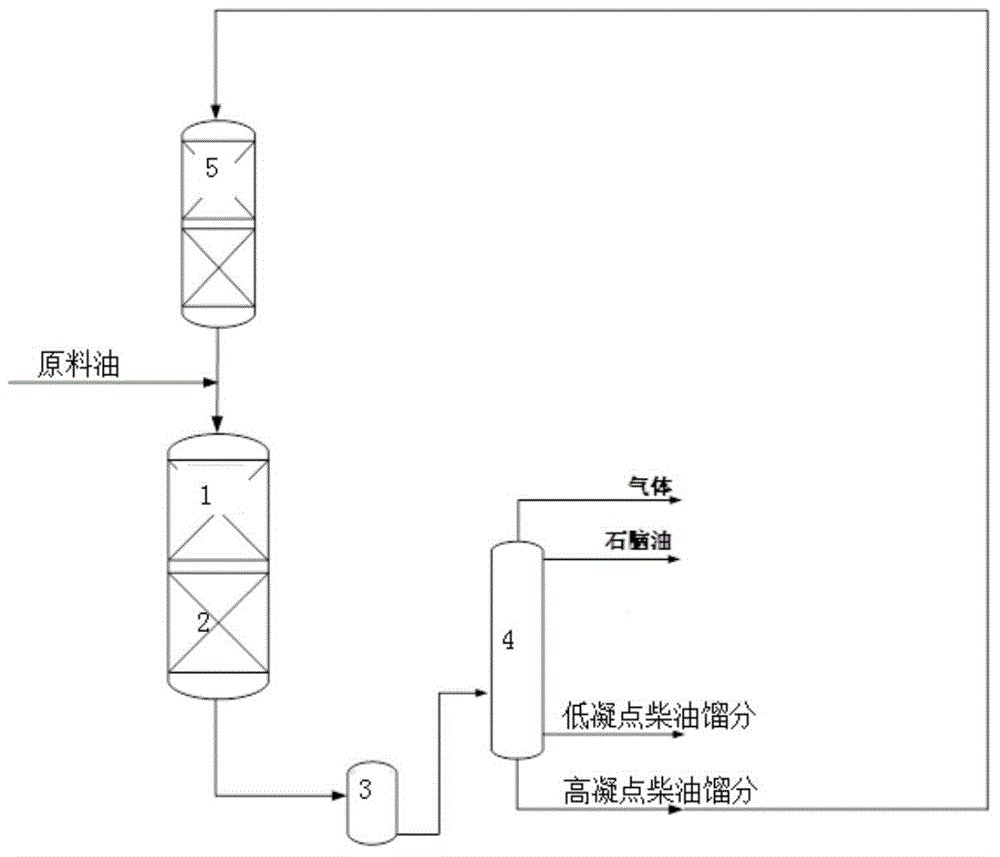

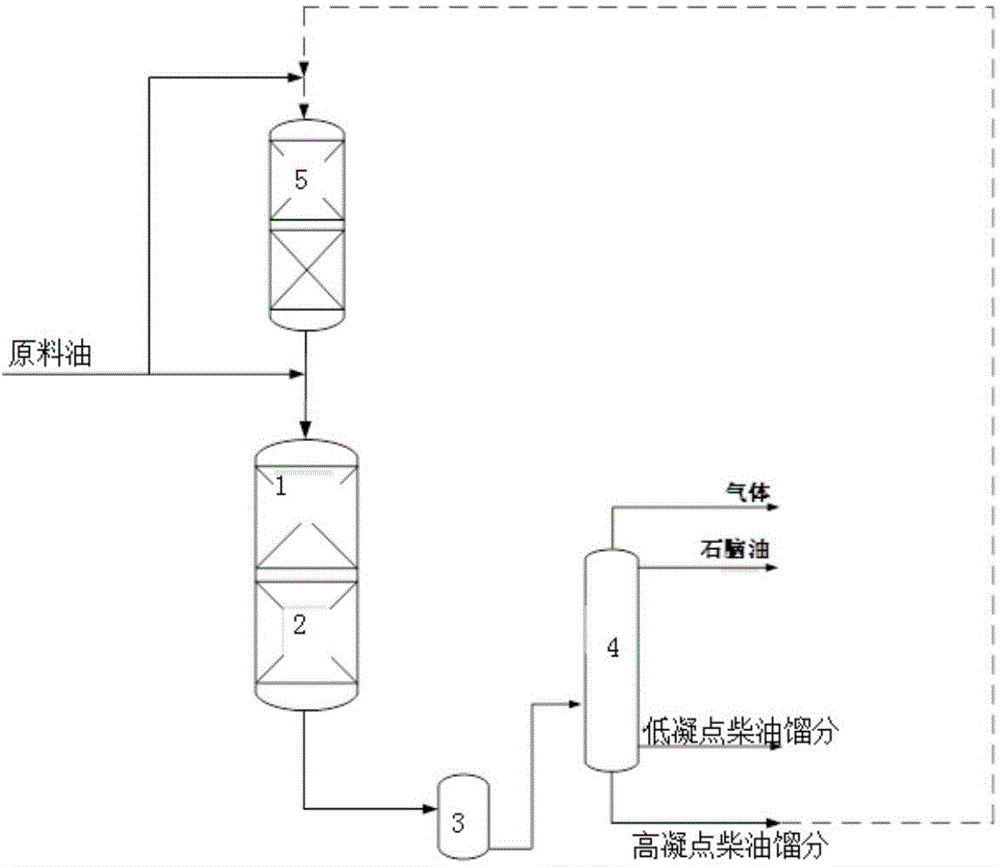

[0063] The raw material used in this example is coked diesel oil A, and its properties are shown in Table 1. This embodiment adopts as figure 1 The process flow shown is carried out, specifically:

[0064] The raw material A is boosted by the raw material pump, mixed with hydrogen, and then enters the first hydrogenation reaction zone 1 after heat exchange and heating furnace preheating, and is contacted with the hydrogenation refining catalyst RS-1000 under the reaction conditions shown in Table 2. Hydrofining reaction; the reaction effluent directly enters the second hydrogenation reaction zone 2 without separation and reacts with the hydrogenation upgrading catalyst RIC-2 to increase the cetane number of diesel oil; the reaction products enter the separation system 3 and fractionation in turn System 4, cutting out gas products, naphtha products, low freezing point diesel fractions and high freezing point diesel fractions; the high freezing point diesel fractions are mixed ...

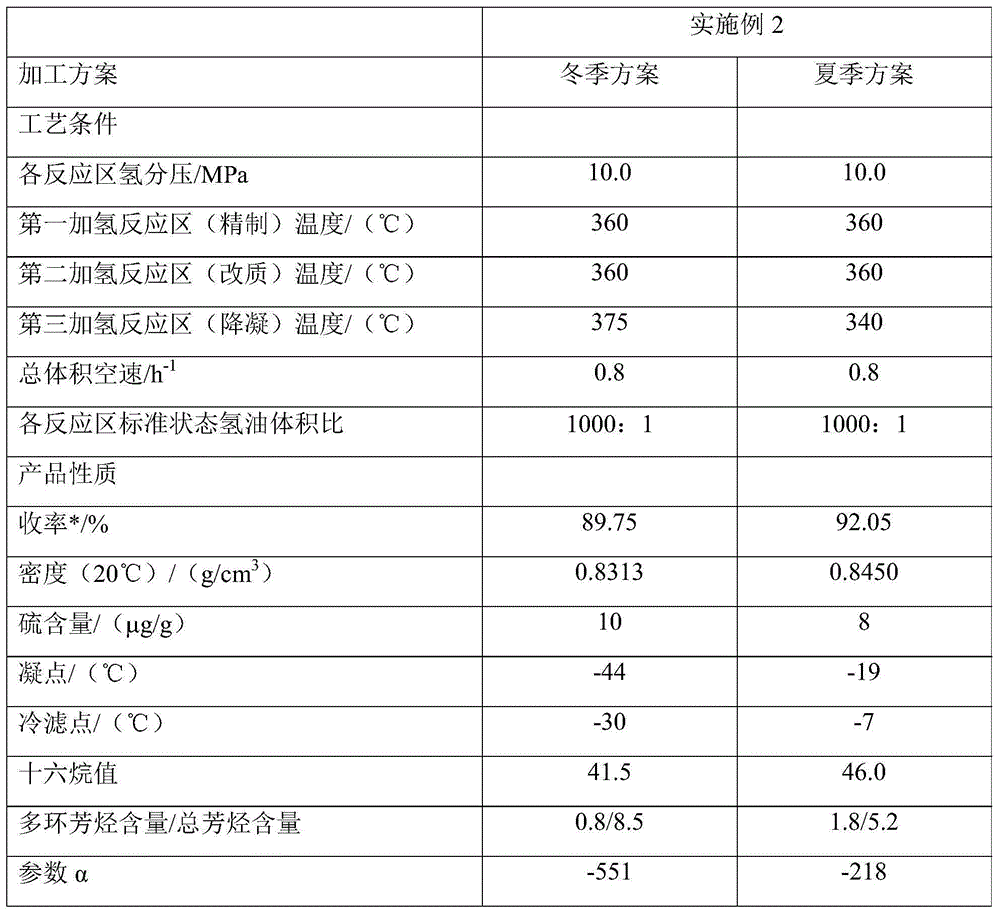

Embodiment 2

[0092] Table 6

Embodiment 3

[0105] Table 8

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidifying point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com