Preparation method of hazelnut oil

A technology of hazelnut oil and hazelnut kernels, which is applied in the field of edible oil, can solve the problems of long production cycle, low production efficiency, and low oil yield by pressing, and achieve high product quality, increase oil yield, and reduce aroma and nutritional components The effect of the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

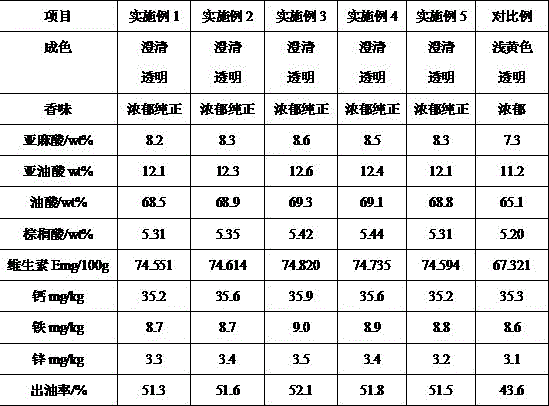

Examples

Embodiment 1

[0018] A preparation method of hazelnut oil is prepared by the following steps:

[0019] 1) Dry 100kg of peeled hazelnut kernels until the water content is 9%, put the dried hazelnut kernels into an airtight container, and store them away from light for 5 days;

[0020] 2) Crush the hazelnut kernels that have been stored away from light into 30 meshes to obtain hazelnut powder;

[0021] 3) Divide the hazelnut powder into two parts on average, one part of the hazelnut powder is rotated and roasted at 110°C for 20 minutes, and the roasted material is sent to an oil press for pressing to obtain a crude oil and a hazelnut meal;

[0022] 4) Press another portion of hazelnut powder directly in the oil press to obtain secondary crude oil and secondary hazelnut meal;

[0023] 5) Crush the primary hazelnut meal and the secondary hazelnut meal to 50 mesh, rotate and bake at 130°C for 30 minutes, and send the baked material to an oil press for pressing to obtain tertiary crude oil and t...

Embodiment 2

[0027] A preparation method of hazelnut oil is prepared by the following steps:

[0028] 1) Dry 100kg of peeled hazelnut kernels until the water content is 10%, put the dried hazelnut kernels into an airtight container, and store them in the dark for 4 days;

[0029] 2) Crush the hazelnut kernels that have been stored away from light into 35 meshes to obtain hazelnut powder;

[0030] 3) Divide the hazelnut powder into two parts on average, one part of the hazelnut powder is rotated and roasted at 105°C for 20 minutes, and the roasted material is sent to an oil press for pressing to obtain a crude oil and a hazelnut meal;

[0031] 4) Press another portion of hazelnut powder directly in the oil press to obtain secondary crude oil and secondary hazelnut meal;

[0032] 5) Crush the primary hazelnut meal and the secondary hazelnut meal to 60 mesh, and rotate and bake at 125°C for 35 minutes. The baked material is sent to an oil press for pressing to obtain tertiary crude oil and t...

Embodiment 3

[0036] A preparation method of hazelnut oil is prepared by the following steps:

[0037] 1) Dry 100kg of peeled hazelnut kernels until the water content is 11%, put the dried hazelnut kernels into an airtight container, and store them in the dark for 3 days;

[0038] 2) Crush the hazelnut kernels that have been stored away from light into 40 meshes to obtain hazelnut powder;

[0039] 3) Divide the hazelnut powder into two parts evenly, one part of the hazelnut powder is rotated and roasted at 100°C for 20 minutes, and the roasted material is sent to an oil press for pressing to obtain a crude oil and a hazelnut meal;

[0040] 4) Press another portion of hazelnut powder directly in the oil press to obtain secondary crude oil and secondary hazelnut meal;

[0041] 5) Crush the primary hazelnut meal and the secondary hazelnut meal to 70 mesh, rotate and bake at 120°C for 30 minutes, and send the baked material to an oil press for pressing to obtain tertiary crude oil and tertiary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com