Method for preparing aluminum alloy sputtering target material

A technology of sputtering target material and aluminum alloy, which is applied in sputtering plating, metal material coating process, ion implantation plating, etc., can solve problems such as complex process, and achieve the effect of improving uniformity and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

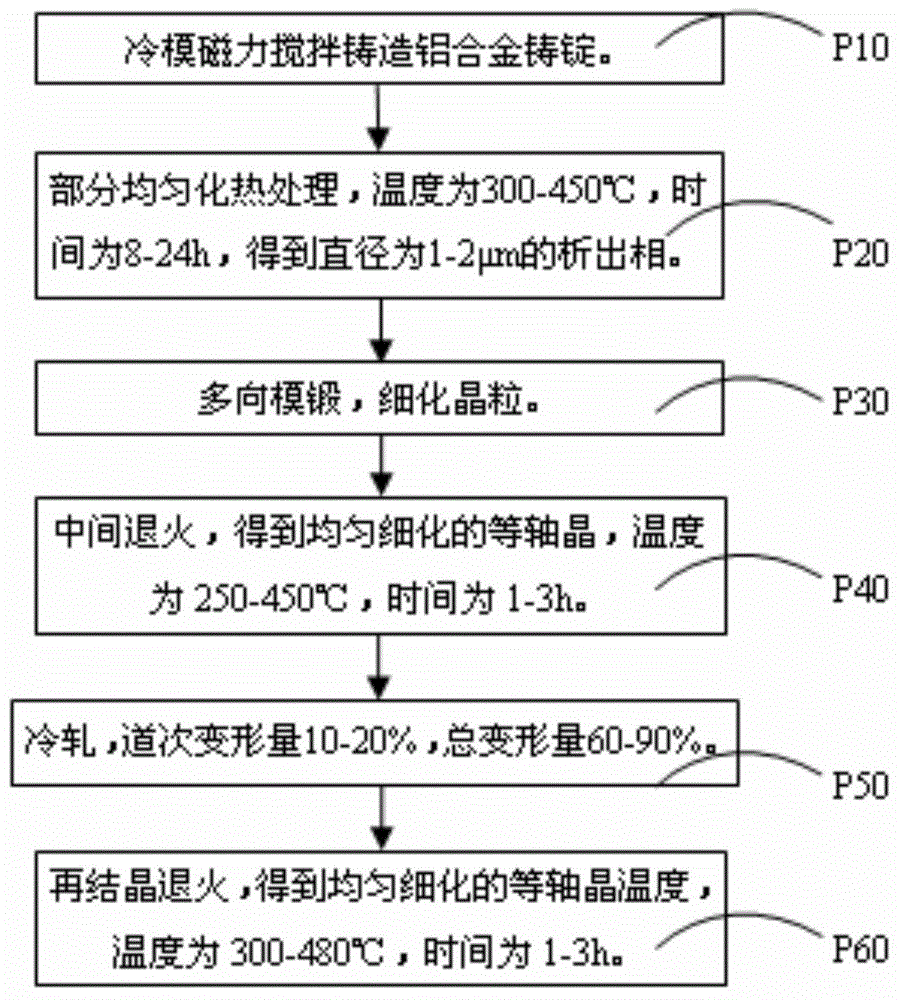

Method used

Image

Examples

Embodiment 1

[0037] 1. Select an Al-0.5wt% Cu alloy ingot, and age the ingot at 300°C for 8 hours.

[0038] 2. Perform axial and radial die forging on the ingot.

[0039] 3. Recrystallization annealing, the annealing temperature is 300°C, and the holding time is 2h.

[0040]4. Carry out cold rolling, the deformation amount is more than 70%, and the deformation amount of each pass is 15%, the purpose is to further refine the grain and enhance the {200} orientation content of the sputtering surface.

[0041] 5. Recrystallization annealing, the annealing temperature is 300°C, and the holding time is 2h, to obtain a uniform and refined recrystallization microstructure.

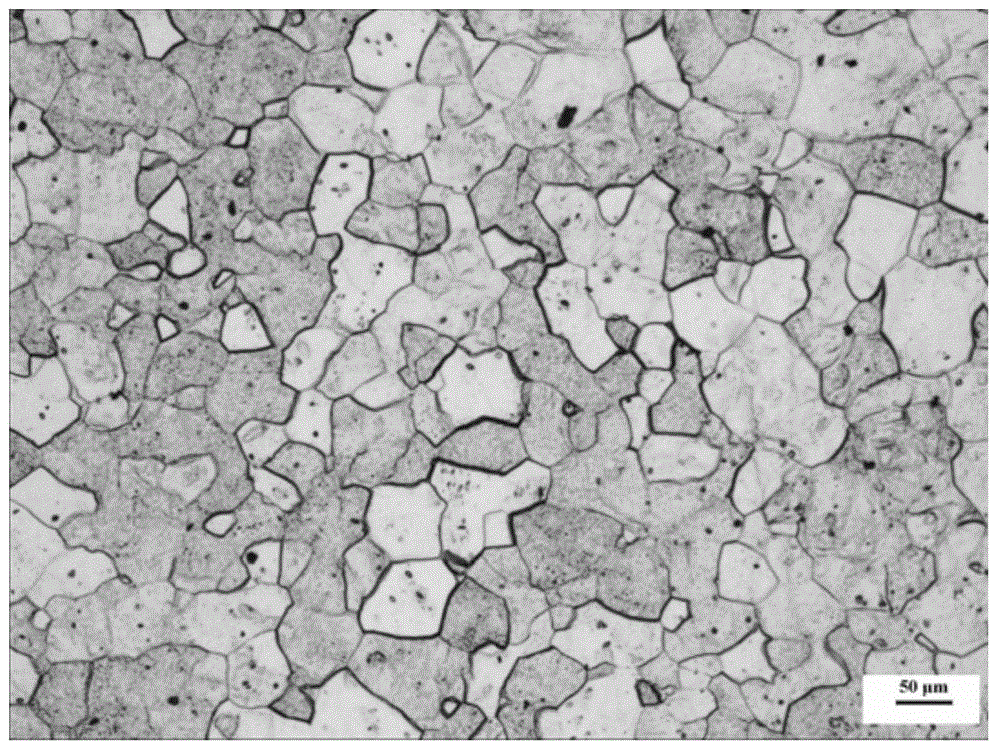

[0042] Determination of the microstructure of the obtained target, the results are as follows figure 2 As shown, it can be seen that the grain size has been significantly refined, the average grain size is about 47.33 μm, and the size distribution is uniform.

Embodiment 2

[0044] 1. Select an Al-1wt% Si alloy ingot, and age the ingot at 400° C. for 16 hours.

[0045] 2. Perform axial and radial die forging on the ingot.

[0046] 3. Recrystallization annealing, the annealing temperature is 450°C, and the holding time is 3h.

[0047] 4. Carry out cold rolling, the deformation amount is more than 70%, and the deformation amount of each pass is 10%, the purpose is to further refine the grain.

[0048] 5. Recrystallization annealing, the annealing temperature is 420°C, and the holding time is 2h, to obtain a uniform and refined recrystallization microstructure.

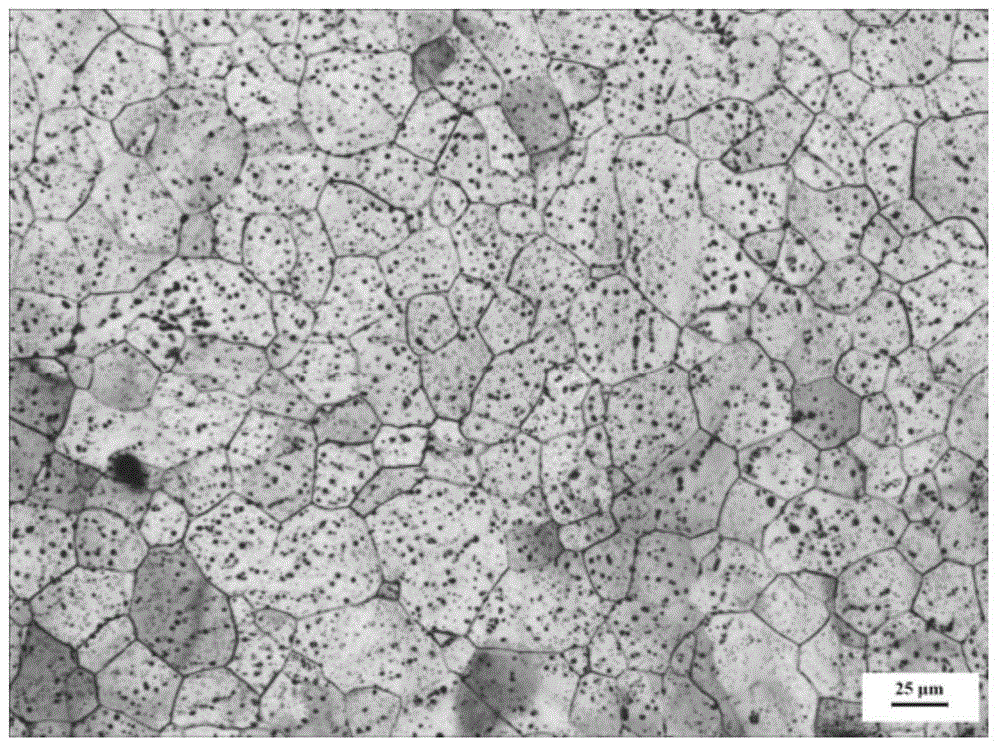

[0049] Determination of the microstructure of the obtained target, the results are as follows image 3 As shown, it can be seen that the grain size has been significantly refined, the average grain size is about 38.85 μm, and the size distribution is uniform.

Embodiment 3

[0051] 1. Select an Al-5wt% Cu alloy ingot, and age the ingot at 450° C. for 24 hours.

[0052] 2. Perform axial and radial die forging on the ingot.

[0053] 3. Recrystallization annealing, the annealing temperature is 450°C, and the holding time is 2h.

[0054] 4. Carry out cold rolling, the deformation amount is more than 70%, and the deformation amount of each pass is 15%, the purpose is to further refine the grain.

[0055] 5. Recrystallization annealing, the annealing temperature is 450°C, and the holding time is 2h, to obtain a uniform and refined recrystallization microstructure.

[0056] Determination of the microstructure of the obtained target, the results are as follows Figure 4 As shown, it can be seen that the grain size has been significantly refined, the average grain size is about 20.21 μm, and the size distribution is uniform.

[0057] From the analysis of the results of the above examples, it can be seen that the microstructure of the target prepared by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com