System and method for blocking bottom plate cracks through air-entrapping silicification

A floor and fissure technology, applied in earthwork drilling, sealing/packing, wellbore/well parts, etc., can solve the problem of incomplete plugging of tiny fissures, achieve better grouting effect, save equipment cost, and increase efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Taking the first recovery working face of a coal mine as an example, in the process of controlling the pressurized water of the bottom plate of the working face, the bottom plate of the coal mine working face is aerated and silicified to seal the cracks in the bottom plate:

[0063] The method for sealing the cracks in the bottom plate by gas-entraining silicification comprises the following steps:

[0064] [Step 1] Carry out fine detection of the hydrogeological conditions of the floor of the 1201 working face, determine that the floor of the working face is coarse sandstone, determine the grouting radius to be 1.5m, and the total grouting height to be 5.8m;

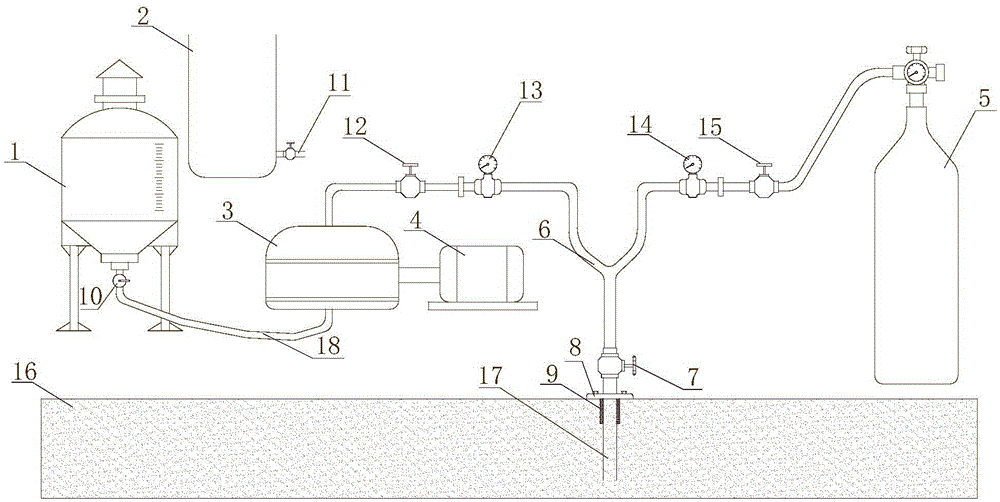

[0065] [Step 2] When the above-mentioned fine detection reaches the standard, grout the coal seam floor, specifically as figure 1 As shown, the sealing of the cracks in the water conduction damage zone of the bottom plate includes the following sub-steps:

[0066] (1) First place the drilling rig or tripod in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com