Tail water power generation system of hydroelectric power plant

A technology of hydroelectric power station and power generation system, which is applied in the direction of hydroelectric power generation, engine components, engine functions, etc. It can solve the problems of high cost and hinder the development of hydropower generation, and achieve the effect of increasing the impact area of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

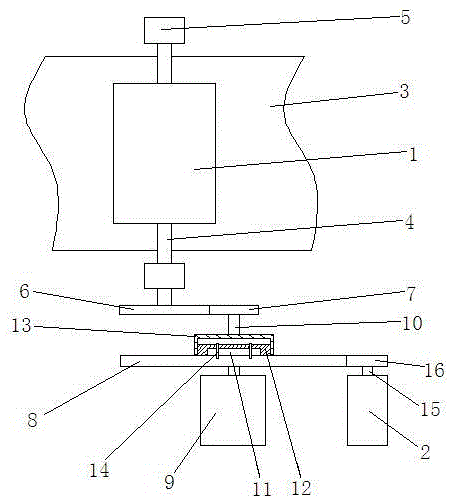

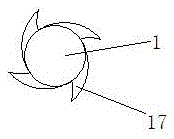

[0017] Such as figure 1 Shown, existing hydroelectric power station dam body, on the dam body of existing these hydroelectric power stations, be provided with the tail water outlet that has passed through hydroelectric station water turbine, in the present invention, also comprise water turbine 1, increasing Speed device and generator 2, the water turbine 1 is placed horizontally above the downstream riverbed 3 close to the tail water discharge port, the blades of the lower part of the water turbine 1 are located under the water surface, and the water flow impacts the blades to drive the water turbine 1 to rotate. The two ends of the turbine shaft 4 of the water turbine 1 are rotationally connected with the base 5 arranged on both sides of the riverbed 3, and the axis line of the turbine shaft 4 is perpendicular to the water flow direction. In order to obtain a larger water flow impact area, the length of the turbine and the length of the blades should be close to the width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com