A method for detecting the center depth of aluminum wheel billet

A technology for wheels and slabs, which is applied in the field of devices for detecting the depth of aluminum wheel slabs, can solve the problems of low machining yield of wheels, out-of-tolerance cap groove dimensions, and increased costs, so as to reduce labor intensity and improve processing Yield rate, effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

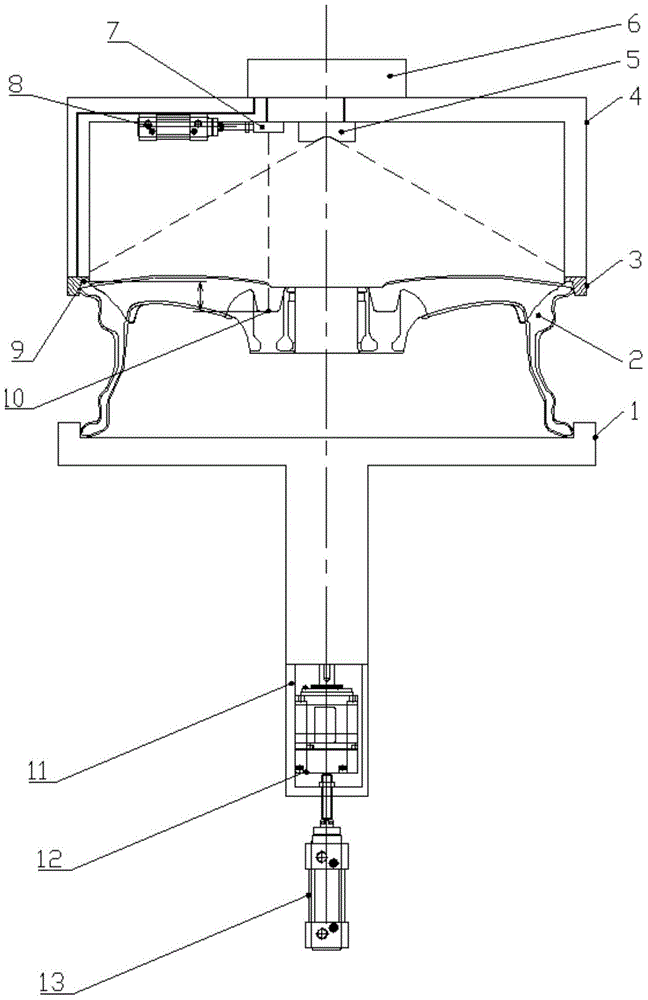

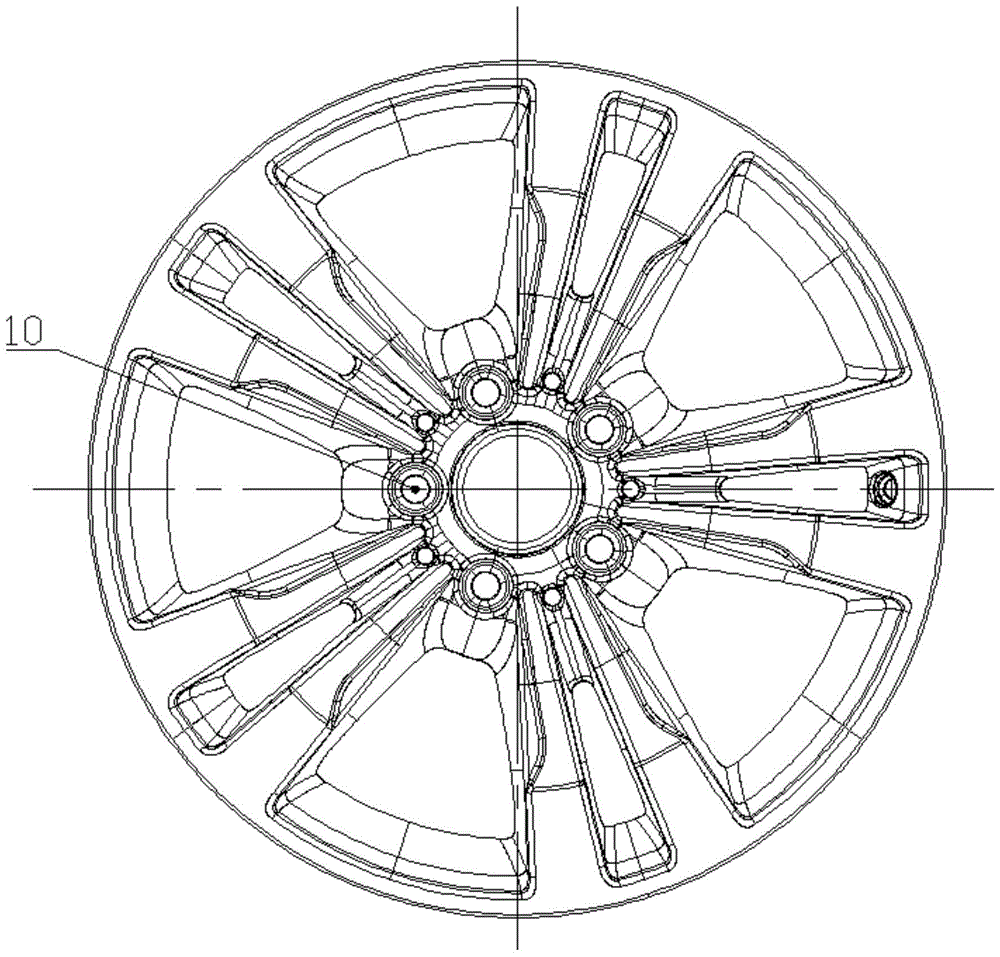

[0018] Book figure 1 Shown: the wheel casting slab (2) is transferred to the roller tray (1), the CCD camera (5) installed on the frame (4) is activated, the image of the wheel casting slab (2) is collected, and output to the programmable The controller (6), the programmable controller (6) performs image recognition on the obtained pictures, recognizes the position of the nearest bolt hole counterbore on the wheel casting blank from the X axis, and places the bolt hole counterbore on the bottom plane of the bolt hole counterbore. Take any point as the wheel center measurement point (10), and calculate the angle between the wheel center measurement point (10) and the X axis, calculate the angle difference, and output the signal to the servo motor (12) to drive the roller table ( 1) Rotate, align the wheel center measuring point (10) on the wheel billet (2) on the X-axis, and transmit the aligned X-axis position of the wheel center measuring point (10) to the programmable contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com