Smoke dust concentration direct-reading monitoring system and method

A monitoring system and concentration technology, applied in measuring devices, suspension and porous material analysis, particle suspension analysis, etc., can solve frequent maintenance, flue gas measurement, gas circuit blockage and other problems, to avoid sampling loss and ensure representativeness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

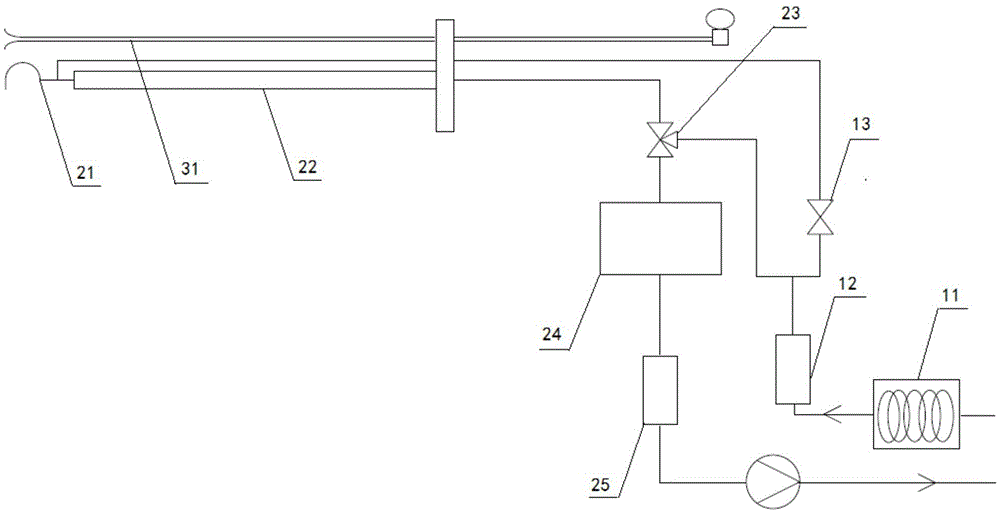

[0042] figure 1 The structural diagram of the smoke concentration direct-reading monitoring system of the embodiment of the present invention is schematically given, as figure 1 As shown, the smoke concentration direct reading monitoring system includes:

[0043] Sampling device 21, velocity measuring device 31, dilution device 22 and measuring device 24, described dilution device is arranged in the flue, and described measuring device adopts beta ray dust meter;

[0044] A gas supply device, the gas supply device includes a pipeline, a heating unit 11 sequentially arranged on the pipeline, a first flow meter 12, and a valve 13, the output end of the valve is connected to the dilution device;

[0045]A switching unit 23, such as a three-way valve, which is used to selectively connect the flue gas inlet of the measuring unit to the pipeline between the dilution device, the valve and the first flowmeter;

[0046] The second flow meter 25 is arranged on the pipeline downstream ...

Embodiment 2

[0059] The smoke and dust concentration direct-reading monitoring system of the embodiment of the present invention is different from Embodiment 1 in that:

[0060] The measuring device includes a light-scattering particle detection unit and a beta ray dust meter arranged sequentially on the pipeline downstream of the switching unit.

[0061] In the monitoring process, use the light scattering particle detection unit and the beta ray dust meter to measure the particle content respectively, and adjust the output value of the light scattering particle detection unit to the output value of the beta ray dust meter; use the light scattering particle detection unit to realize Continuous measurement of soot concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com