Metal wire rope on-line monitoring method and device

A metal wire rope and monitoring device technology, applied in the direction of material magnetic variables, etc., can solve problems such as being unsuitable for large-scale use, having coating detection effects, and high-cost X-rays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

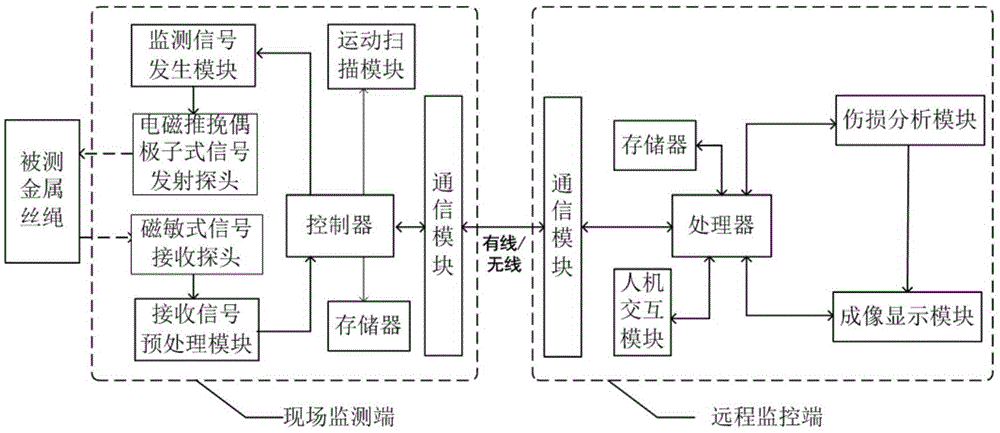

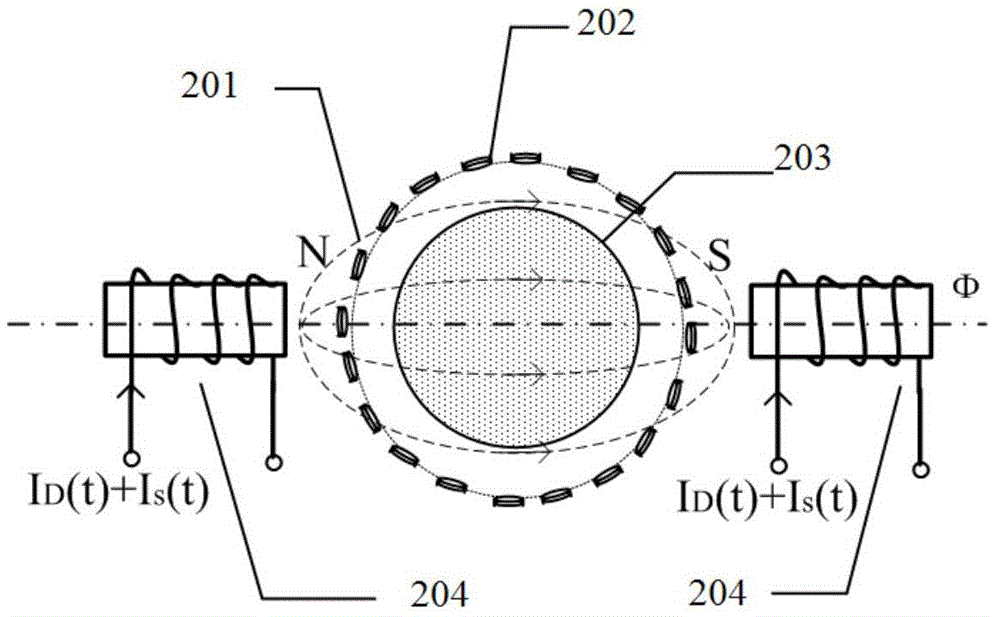

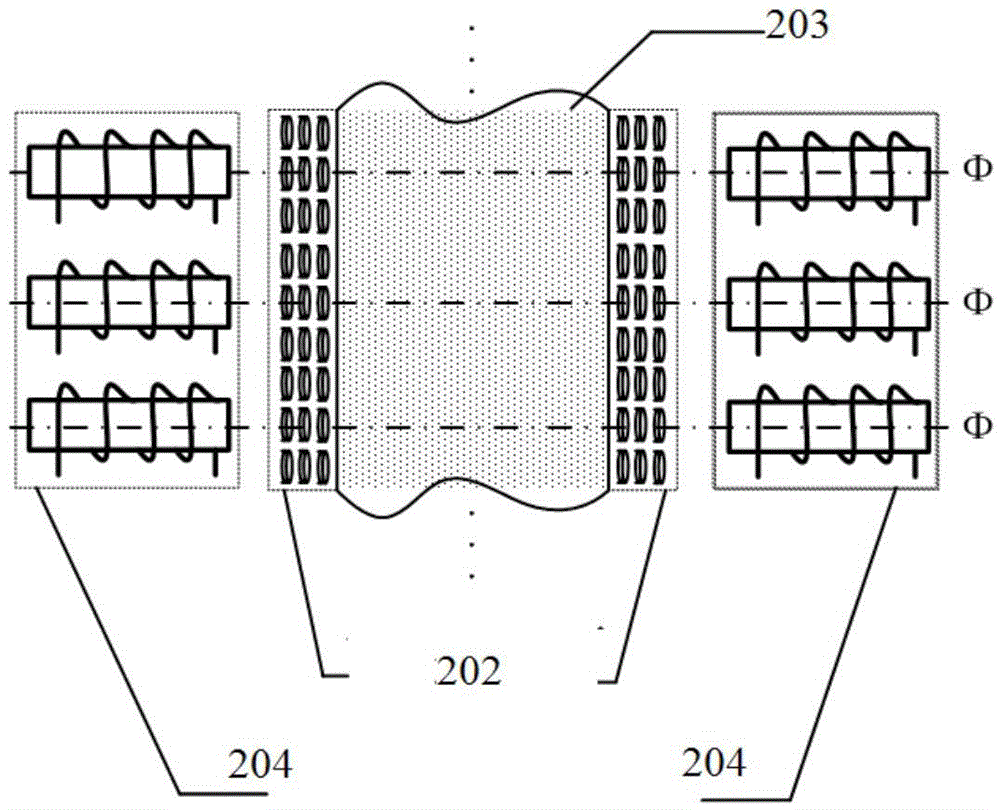

[0058] This example organically combines information technology, electromagnetic field technology and non-destructive testing technology. According to Maxwell's equations, an electromagnetic push-pull dipole is used to generate a broadband alternating magnetic field, and the metal wire rope to be tested is placed in the magnetic field. The component obtains the information of the induced magnetic field, obtains the distribution characteristics of its magnetic parameters (such as: magnetic permeability) and electrical parameters (such as: electrical conductivity), and combines the difference between the material of the damaged part and the measured wire rope, so that Realize non-destructive testing and damage location. The invention has the advantages of high precision, non-contact, harmless to people and the environment, small size, low power consumption, simple hardware and low cost, etc. Compared with the existing passive detection methods such as magnetic flux leakage detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com