Titanium dioxide functionalization multiwalled carbon nanotube nano composite optical limiting material and preparation method thereof

A technology of multi-walled carbon nanotubes and titanium dioxide, applied in optics, nonlinear optics, instruments, etc., can solve the problems of poor dispersion, restrict the application of multi-walled carbon nanotubes, and high light confinement threshold, and achieve good nonlinear optical absorption function. and the effect of light confinement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The pre-prepared tetrabutyl titanate (250 mg) was sonicated in a mixed solvent of deionized water (6 mL) and ethanol (3 mL) for half an hour, and then transferred to a polytetrafluoroethylene autoclave, at 160 ° C , hydrothermal reaction for 72 hours. After the reaction, after the reaction solution was cooled to room temperature, the reaction solution was filtered with a 0.45 μm nylon membrane, washed with deionized water and ethanol respectively, and then dried overnight in vacuum to obtain anatase titanium dioxide.

Embodiment 2

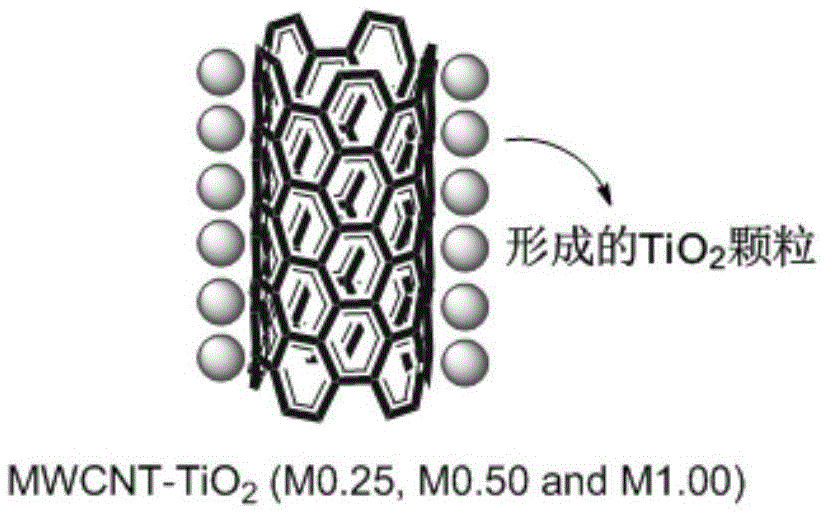

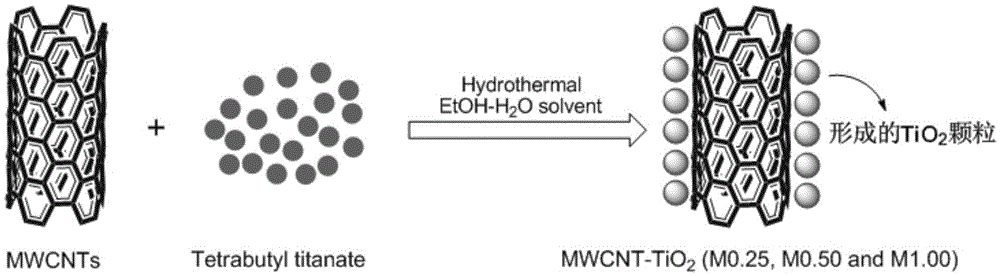

[0031] The pre-prepared multi-walled carbon nanotubes (50 mg) and tetrabutyl titanate (250 mg) were sonicated in a mixed solvent of deionized water (6 mL) and ethanol (3 mL) for half an hour, and then transferred to a polytetrafluoroethylene high pressure In the reaction kettle, under the condition of 160°C, hydrothermal reaction was carried out for 72 hours. After the reaction, after the reaction solution was cooled to room temperature, the reaction solution was filtered with a 0.45 μm nylon membrane, washed with deionized water and ethanol respectively, and then dried overnight in vacuum to obtain titanium dioxide functionalized multi-walled carbon nanotubes Nanocomposite M0.25.

[0032] Wherein, the mass ratio of tetrabutyl titanate to multi-walled carbon nanotubes is 5:1.

Embodiment 3

[0034] The pre-prepared multi-walled carbon nanotubes (50 mg) and tetrabutyl titanate (500 mg) were sonicated in a mixed solvent of deionized water (6 mL) and ethanol (3 mL) for half an hour, and then transferred to a polytetrafluoroethylene high pressure In the reaction kettle, under the condition of 160°C, hydrothermal reaction was carried out for 72 hours. After the reaction, after the reaction solution was cooled to room temperature, the reaction solution was filtered with a 0.45 μm nylon membrane, washed with deionized water and ethanol respectively, and then dried overnight in vacuum to obtain titanium dioxide functionalized multi-walled carbon nanotubes Nanocomposite M0.50.

[0035] Wherein, the difference between embodiment 3 and embodiment 2 lies in that the mass ratio of tetrabutyl titanate to multi-walled carbon nanotubes is 10:1. Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap