Voltage peak control circuit applied to DC-DC converter

A DC-DC, voltage peak technology, applied in the control/regulation system, DC power input conversion to DC power output, instruments, etc., can solve the problems of serious electromagnetic interference, long adjustment time, slow dynamic response, etc., to achieve voltage dynamics The effect of good characteristics, simple and clear structure, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

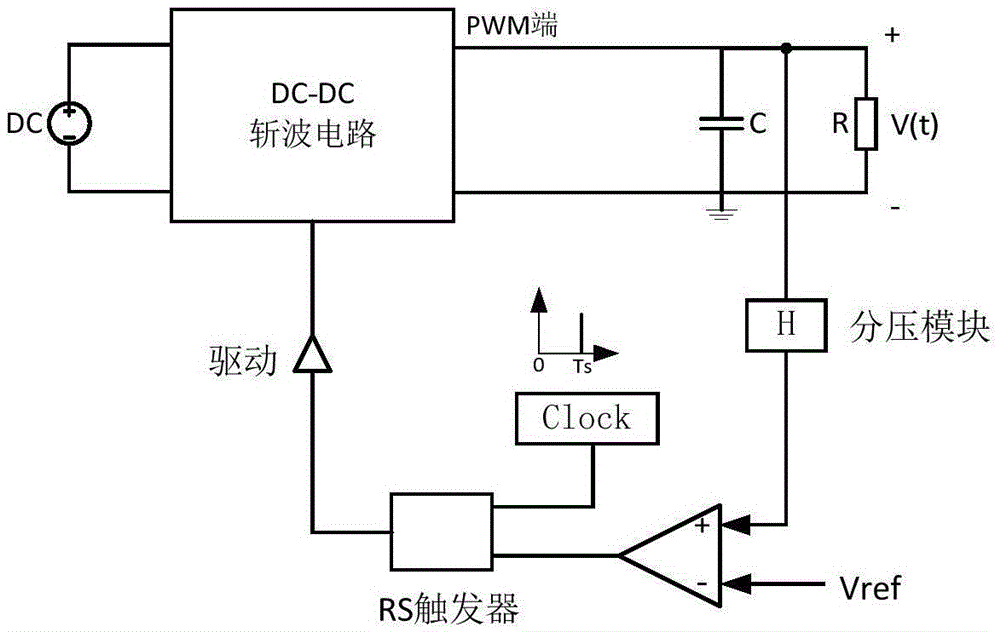

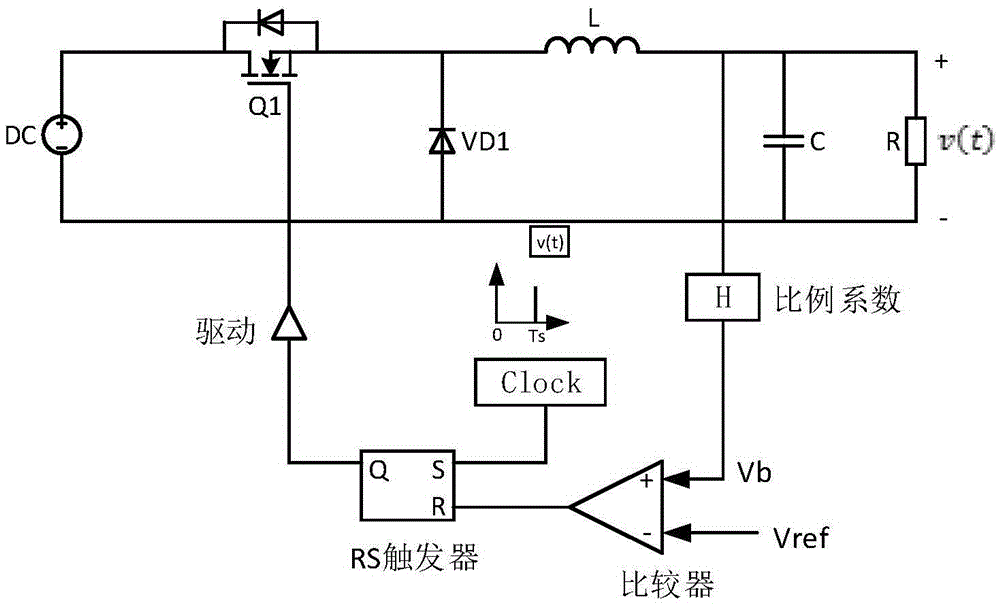

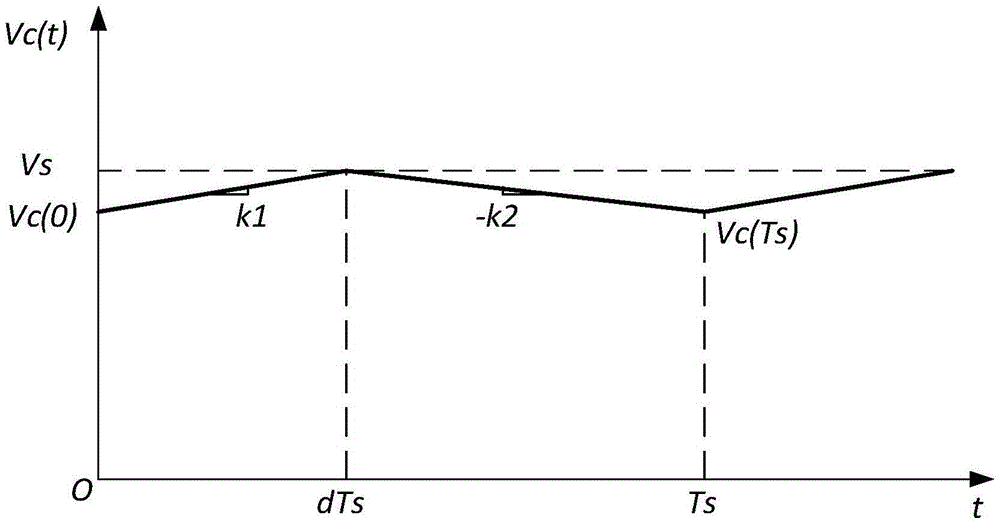

[0018] figure 1 It is a schematic diagram of the voltage peak control circuit applied to the DC-DC chopper circuit, taking the Buck chopper circuit as an example, the voltage peak control circuit applied to the Buck circuit, such as figure 2 As shown, it includes a DC power supply DC, a MOSFET switch tube Q1 with an anti-parallel diode, a diode VD1, an inductor L, a capacitor C, and a load resistor R to form the main power circuit; and A proportional link (generally obtained by dividing voltage by resistors, that is, a voltage dividing module), a comparator, an RS flip-flop, a clock module, and a driving module constitute a voltage peak control loop. The main power circuit Buck realizes the function of step-down, and the input-output voltage relationship in the steady state of continuous operation (CCM) mode is:

[0019] V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com