Electric floor wiping machine

A mopping machine and electric technology, applied in the field of ground cleaning, can solve the problems of inability to remove the dirt of mopping cloth at any time, reducing the working efficiency of mopping mop, complicated structure of mopping mop, etc., so as to achieve good mopping effect and simple structure. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

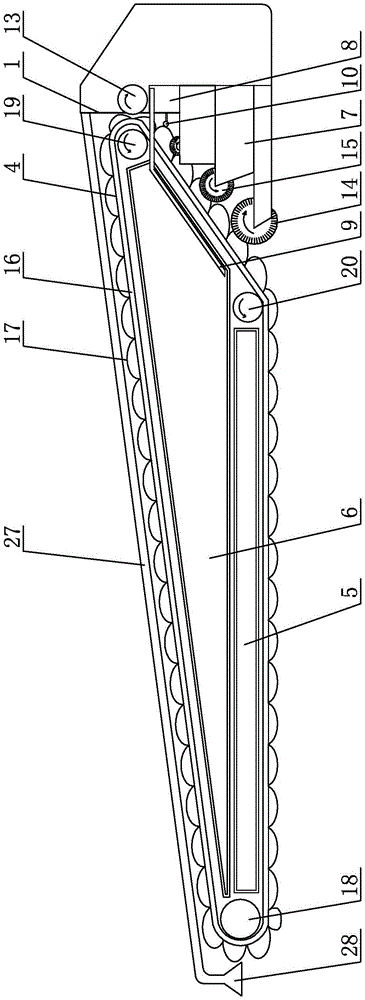

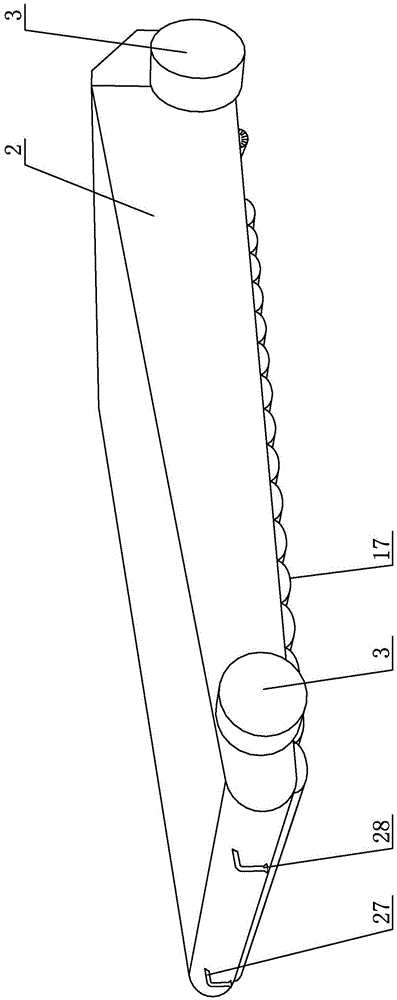

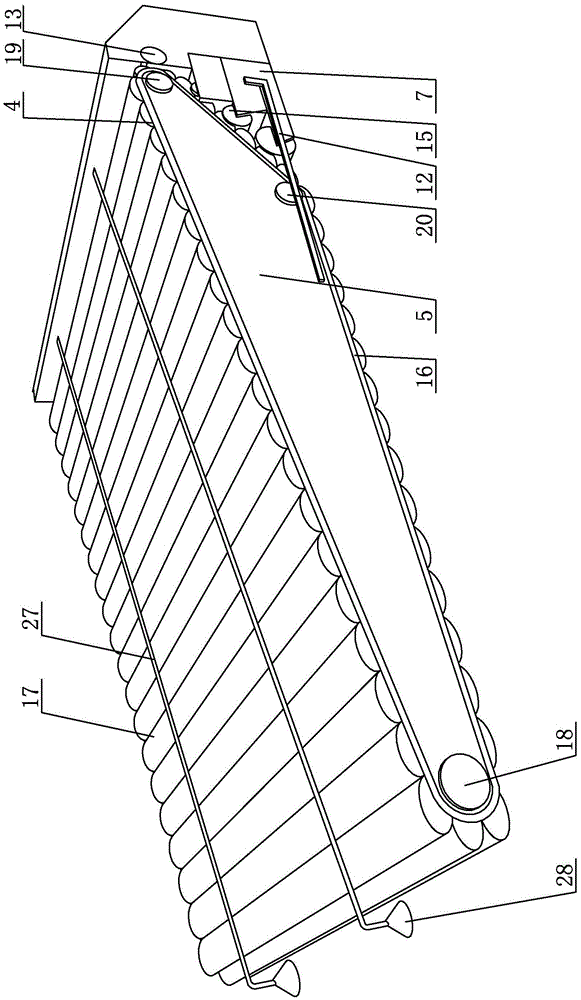

[0028] Specific implementation mode one: as Figure 1 ~ Figure 3 and Figure 7 ~ Figure 11 As shown, what is described in this embodiment is an electric mopping machine, which includes a frame 1, a housing 2 and four walking wheels 3 with built-in motors. The housing 2 is covered on the frame 1 and two The left and right sides of the front end of the frame 1 and the left and right sides of the rear end are respectively equipped with a walking wheel 3 with a built-in motor. The electric mopping machine also includes an electric mopping mechanism 4, a sewage tank 5, a clear water Case 6, dirt collection box 7, water pump 8, water inlet pipe 9, water spray pipe 10, connecting pipe 11, sewage pipe 12, extrusion roller motor 13, cleaning brush 14 and a plurality of cleaning roller motors 15;

[0029]The electric mopping mechanism 4 includes an endless belt 16, a mopping cloth or a collodion layer 17, a front roller motor 18, a rear roller motor 19 and an intermediate transition ro...

specific Embodiment approach 2

[0036] Specific implementation mode two: as figure 1 , image 3 , Figure 7 , Figure 8 and Figure 10 As shown, in the electric mopping machine described in Embodiment 1, the mopping cloth 17 is a microfiber cloth, which has a good water absorption effect, so that the mopping cloth 17 wipes the ground cleaner.

specific Embodiment approach 3

[0037] Specific implementation mode three: as Figure 9 As shown, in the electric mopping machine described in Embodiment 1, the outer peripheral surfaces of the front roller motor 18, the rear roller motor 19 and the intermediate transition roller motor 20 are all processed with a plurality of trapezoidal shapes along their respective circumferential directions. Tooth groove 22, the inner surface of the endless belt 16 is provided with a plurality of trapezoidal teeth 23 along the ring direction, the plurality of trapezoidal teeth 23 are arranged side by side along the width direction of the endless belt 16, all the trapezoidal teeth 23 of the endless belt 16 All cooperate one by one with a plurality of trapezoidal tooth slots 22 on the front roller motor 18, the rear roller motor 19 and the intermediate transition roller motor 20, which can prevent the endless belt 16 from slipping and make the overall transmission of the electric mopping machine more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com