Hobbing cutter and cutter assembly for processing seaweed materials

A technology of cutting knife assembly and rolling knife, which is applied in the direction of grain processing, etc., can solve the problems of low production efficiency and poor work reliability, and achieve the effects of improving output rate, complete separation, and improving foreign matter picking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0053] Such as figure 1 As shown, the cutter assembly for processing seaweed materials according to the present invention mainly includes: a rolling cutter 1 and an elastic joint. The hob cutter is adapted to press against and roll on the resilient engagement member.

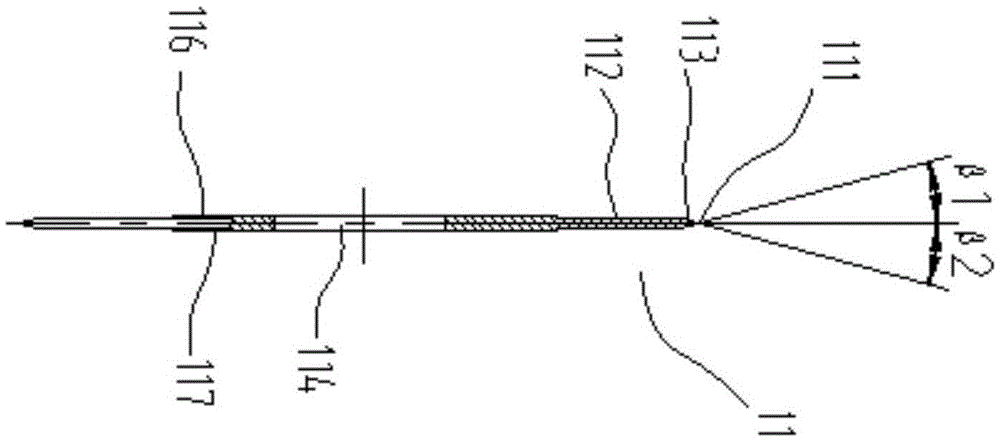

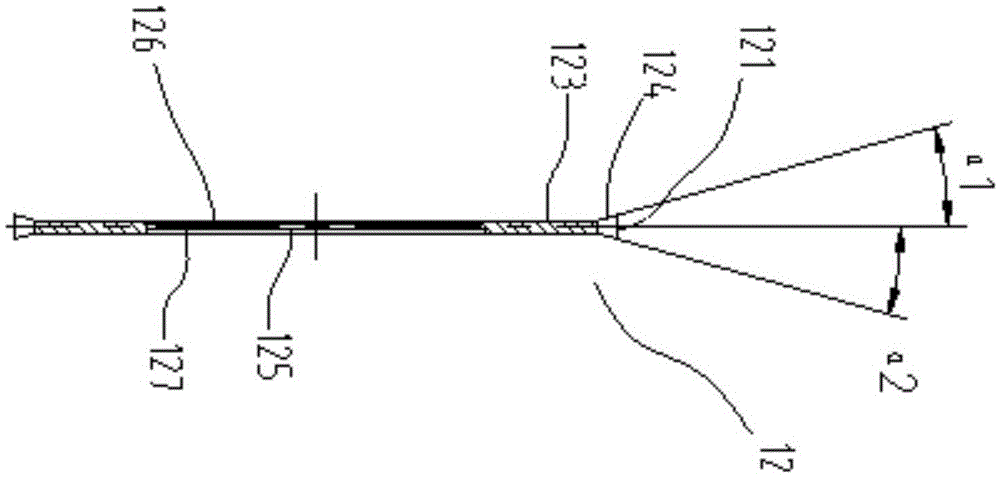

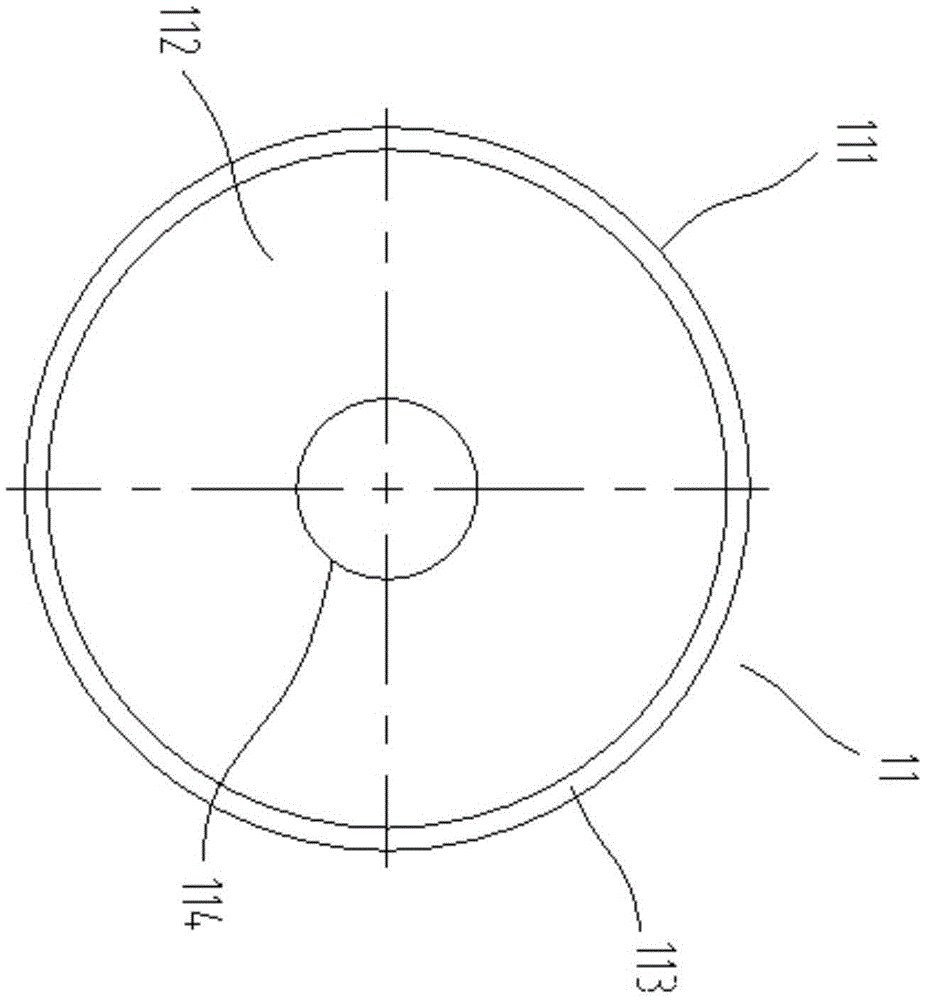

[0054] Such as figure 2 As shown, the hob cutter 1 is integrally formed, and the part with a larger radial dimension is the main part, which can rotate around its rotation axis under power drive. The main part has a peripheral wall, and the peripheral wall is perpendicular to the rotation axis The cross-section is in the shape of a closed curve, and the outer peripheral wall is provided with a plurality of blades in the shape of a closed curve. figure 2 The reference numerals 111 and 121 together enclose the aforementioned blade, and the blade in the shape of a closed curve defines a groove 122 corresponding to the shape of the blade. The size and shape of the blade can be set according to the processing re...

no. 2 approach

[0059] Based on the first embodiment, the hob cutter forming method is modified.

[0060] Such as Figure 4 with 5 As shown, the hob cutter 1 is formed by assembling a plurality of components. Hob cutter 1 includes: blade sets 11 , 12 , lock nut 13 and mandrel 14 . The blade set is set on the mandrel 14, and the two ends are fastened with lock nuts 13 respectively. The blade set includes a plurality of disc knives 11 and a plurality of toothed knives 12 arranged coaxially with each other. The disc cutter 11 is a disc-shaped structural member, and a disc blade 111 extending in the circumferential direction is formed at the outer circumference of the disc cutter 11 . Toothed knife 12 is also generally disc-shaped, and its outer circumference is distributed with some knife teeth, and the addendum of knife tooth forms toothed knife blade 121. The radial dimension of the cutting edge 111 of the disc knife 11 is equal to the radial dimension of the cutting edge 121 of the serra...

no. 3 approach

[0073] Based on the second embodiment, the blade portion of the disc knife and the teeth of the toothed knife are modified.

[0074] Such as Figure 8-10b As shown, the hob cutter 1 is formed by assembling a plurality of components. The hob cutter 1 includes: a blade set, a lock nut 13 and a mandrel 14 . The blade group is sleeved on the mandrel 14, and the two ends are fastened with locking nuts 13 respectively. The blade set includes a plurality of disc knives 11 and a plurality of toothed knives 12 arranged coaxially with each other. The disc cutter 11 is a disc-shaped structural member, and a disc cutter blade 111 extending in the circumferential direction is formed at its outer circumference. Toothed knife 12 is also generally disc-shaped, and its outer circumference is distributed with some knife teeth, and the addendum of knife tooth forms toothed knife blade 121. The diameter of the outer circle of the disc cutter 11 is equal to the diameter of the outer circle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com