Glue-pouring machine

A glue filling machine and glue conveying technology, which is applied to coatings and devices that apply liquid to the surface, etc., can solve the problems of non-dry glue filling, inaccurate flow, and customer complaints, so as to reduce economic losses and improve product quality. Quality, improve the effect of abnormal ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

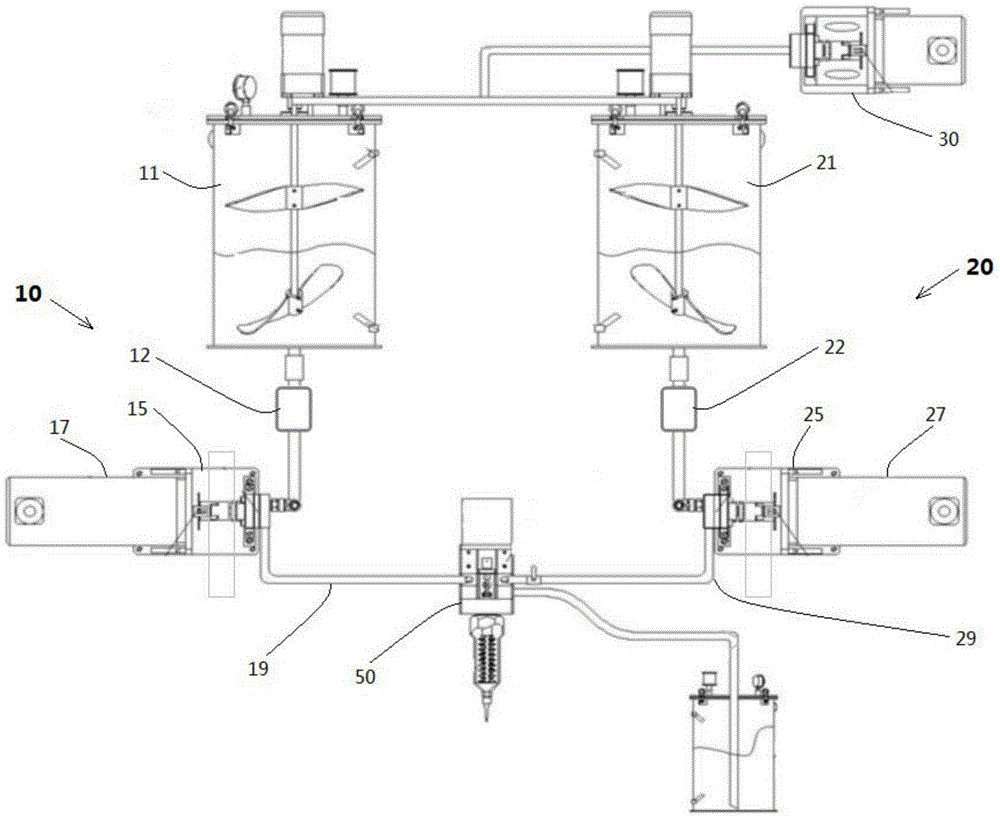

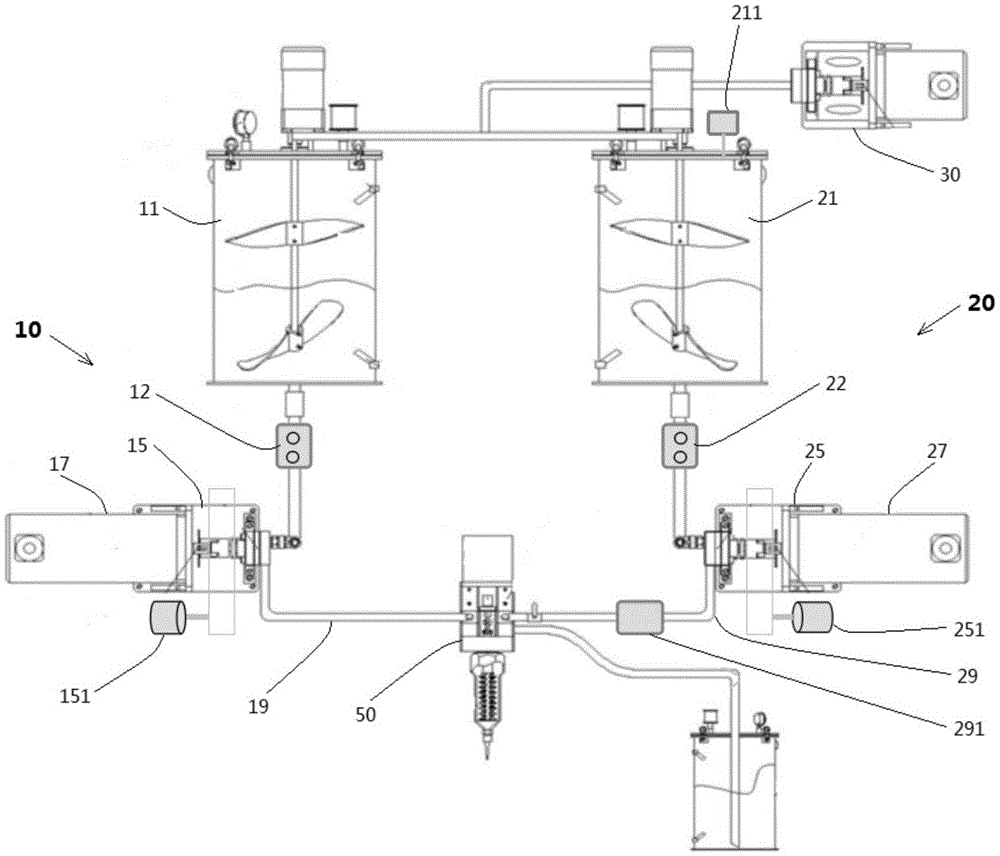

[0031] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] Instructions attached figure 2 A structural schematic diagram of the present invention is provided,

[0033] For problem 2, the lack of real-time monitoring of the pressure in the storage tank, the glue filling machine of the present invention adds a pressure detection device 211 on the storage tank 21 to display the real-time pressure in the tank. The upper and lower limit pressure ranges can be set. When the actual pressure value is not within the set upper and lower limit ranges, the control system will send an alarm shutdown signal, and the equipment will perform an alarm shutdown action. The pressure detection device 211 is preferably an electronic pressure gauge. The electronic pressure gauge can be a conventional digital display pressure gauge, which is installed on the upper end of the curing agent storage tank and communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com