Investment casting method of knotter rack

A technology of investment casting and knotter, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of manpower, material and financial resources, difficulty in demoulding wax molds, and difficulty in wax mold manufacturing. To achieve the effect of shortening the production cycle, strong operability and repeatability, and shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

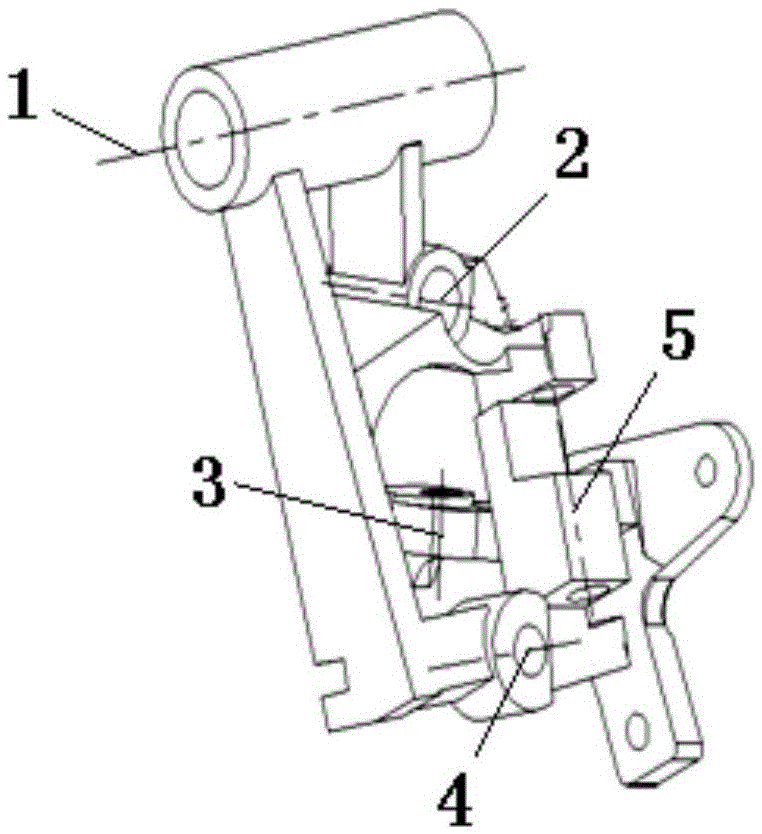

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

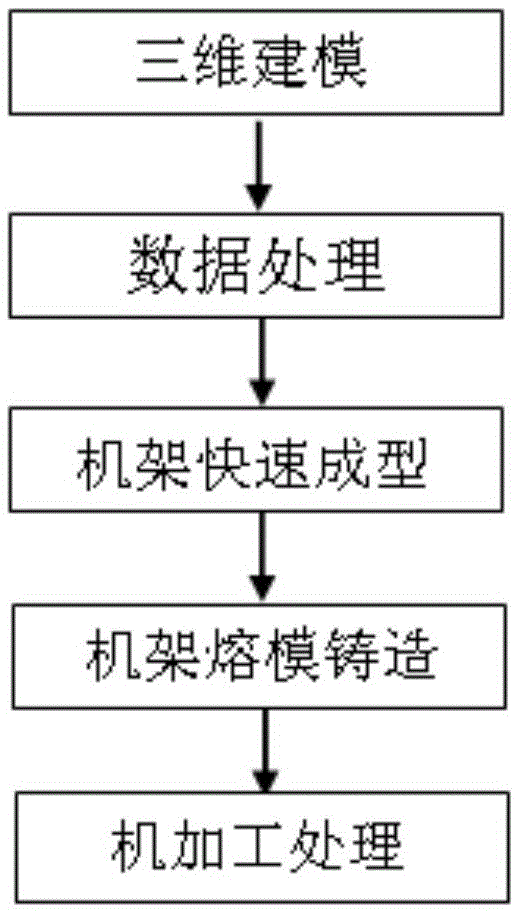

[0023] Such as figure 2 As shown, the investment casting method of the knotter frame of the present invention comprises the following steps:

[0024] 1) Three-dimensional modeling of the knotter frame through three-dimensional software: according to the design requirements, the three-dimensional modeling of the knotter frame is carried out in the CATIA three-dimensional software environment, and the three-dimensional model is enlarged and changed according to a certain proportion according to the process requirements Shaft hole size, reserved machining allowance for machining, and finally, output the 3D model as an STL file format.

[0025] 2) Perform data processing on the STL file of the three-dimensional model of the rack through layered processing software: using Magics software, firstly inspect and repair the STL file of the three-dimensional m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com