Self-centering spring clamping device

A spring clamping and self-centering technology, which is applied in the direction of gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of time-consuming and laborious adjustment, inconvenient installation and installation of shaft gears, and long adjustment time, so as to achieve convenient installation and use , Easy to lock and ensure the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

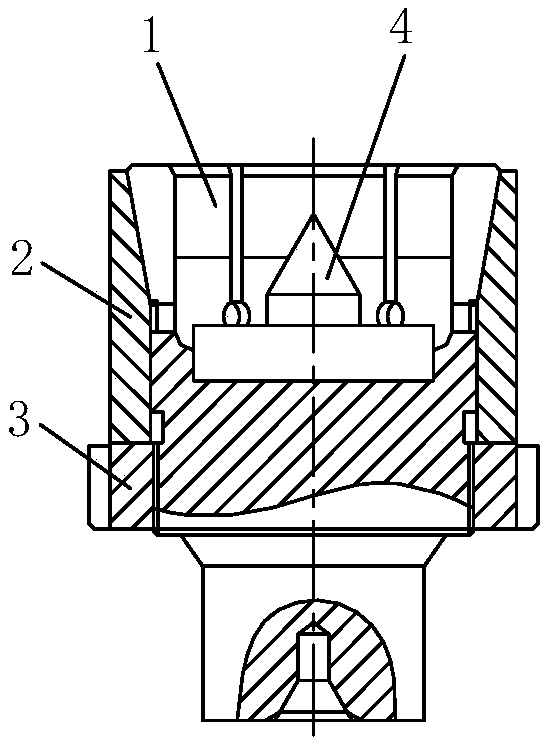

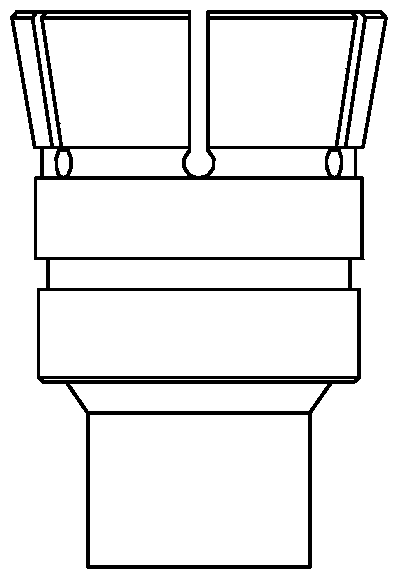

[0029] Such as figure 1 with figure 2 As shown, the present invention includes an elastic collet body 1, a sliding taper sleeve 2 and a lock nut 3. The sliding taper sleeve 2 is sleeved on the clamping portion of the elastic collet body 1 and can be moved along the clamping portion Sliding up and down, the locking nut 3 is threaded on the collet body 1 and is used to push the sliding taper sleeve 2 to slide, the locking nut 3 is located under the sliding taper sleeve 2, the elastic collet body 1 A self-centering top 4 is fixed in the clamping hole.

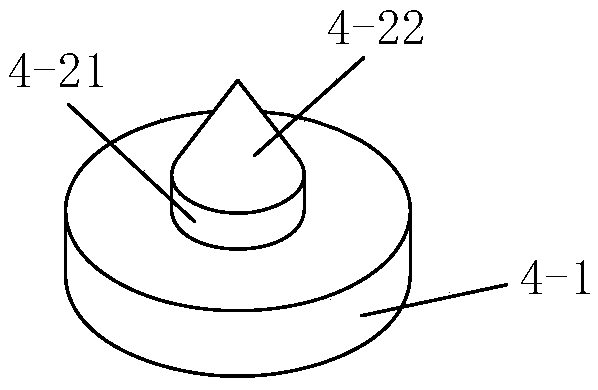

[0030] Such as image 3 As shown, the self-centering center 4 includes a center seat 4-1 and a center head 4-2, the center head 4-2 is fixed at the top center of the center seat 4-1, and the center seat 4-1 is fixed At the center of the clamping hole; the role of the center seat 4-1 is to fix the center head 4-2 on the one hand, and to stably fix the self-centering center 4 in the clamping hole on the other hand.

[0031] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com