A preparing method of an aqueous stable graphene dispersion liquid

A technology of dispersion liquid and alkene water, applied in the field of graphite powder, can solve the problems of environmental pollution waste, loss of physical and chemical properties of graphene, etc., and achieve the effects of good dispersibility, convenient operation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 0.1g of polycarboxylate superplasticizer to 100mL water, stir magnetically for 1-2min, add 0.5g of γ-diethylenetriaminopropylmethyldimethoxysilane, stir magnetically for 2-3min until uniform dispersion;

[0024] (2) Add 0.1 g of graphene into the prepared dispersion, stir magnetically for 2-3 minutes, and disperse ultrasonically for 1 hour to obtain a highly dispersible and stable graphene aqueous dispersion.

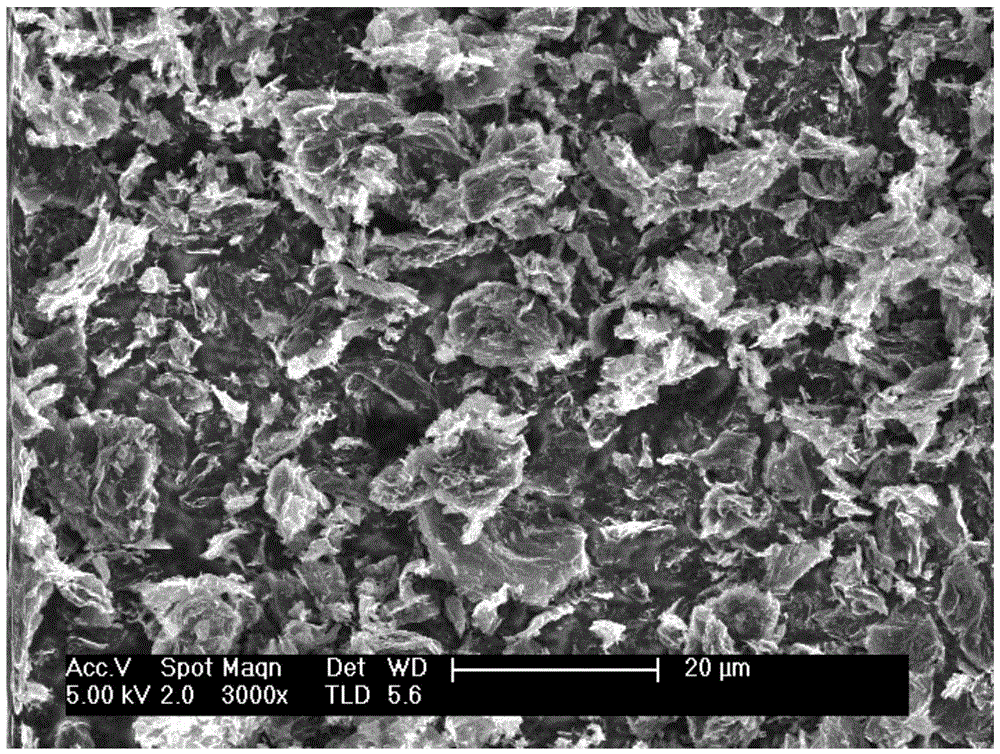

[0025] From figure 1 It can be seen that graphene spontaneously agglomerates due to its own van der Waals force, resulting in uneven dispersion during use and failing to achieve the desired effect.

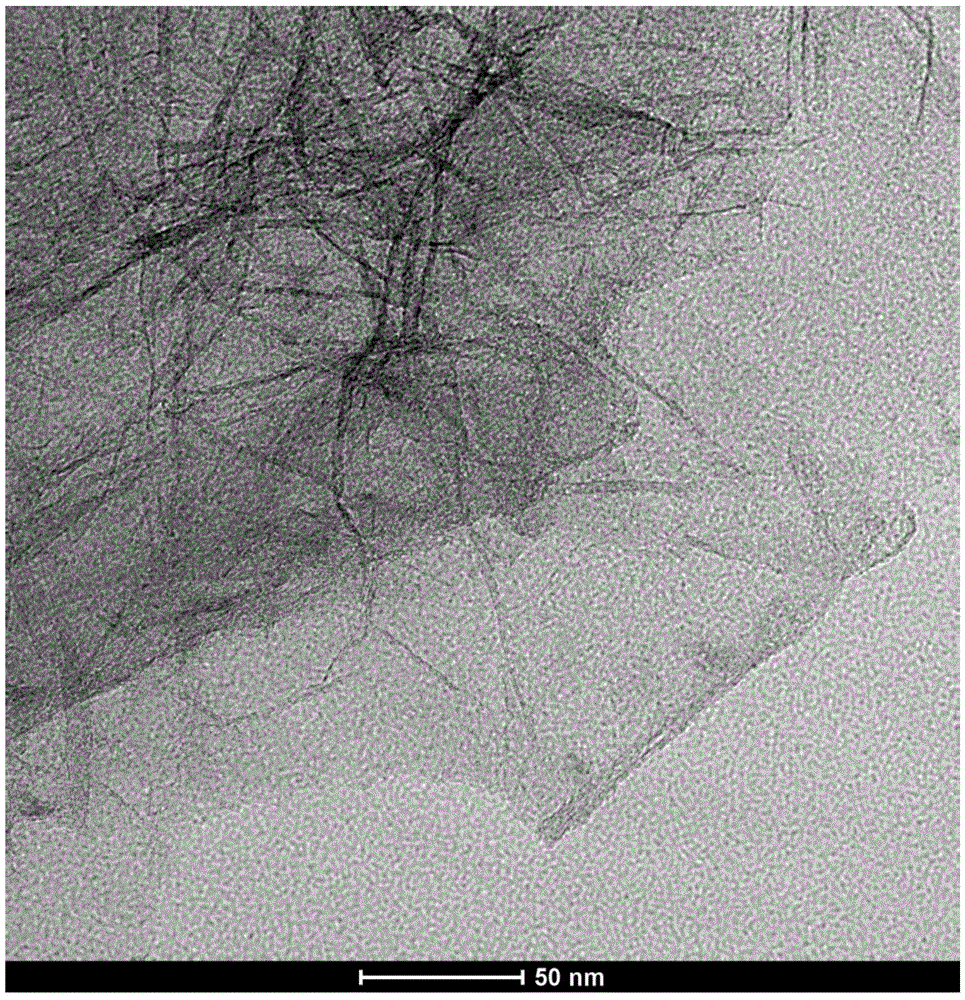

[0026] From figure 2 It can be seen that graphene presents a multi-layer transparent state, indicating that the dispersion effect is obvious.

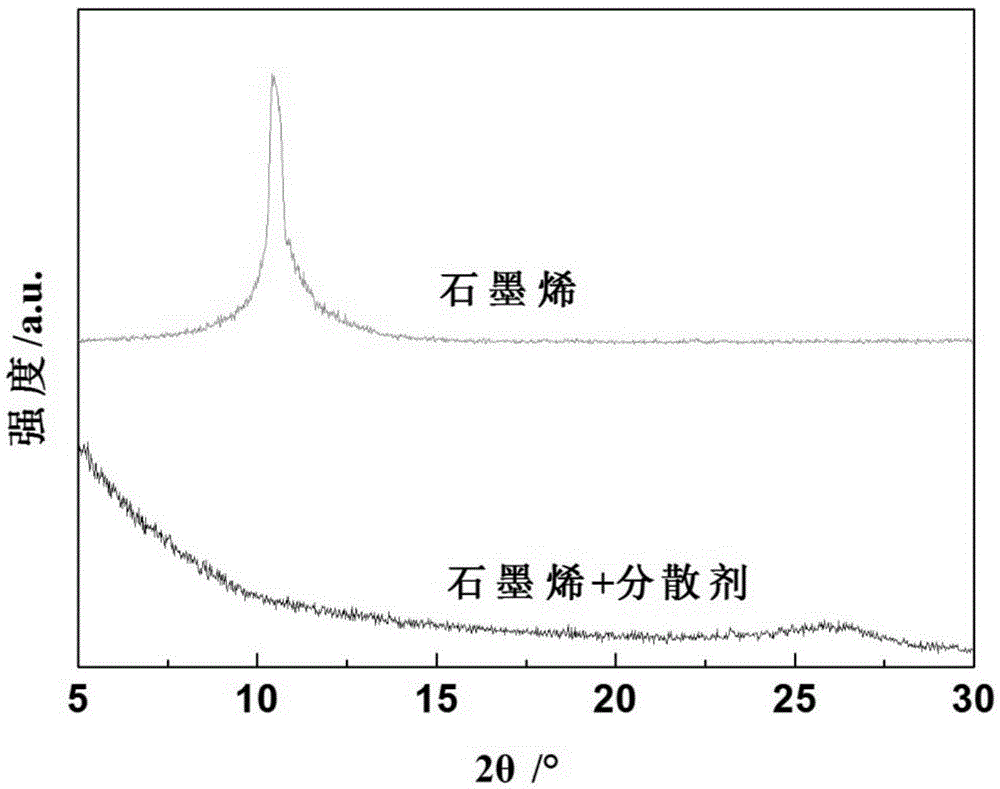

[0027] Such as image 3 , graphene has a strong diffraction peak around 2θ=11°, and the graphene dispersed by the dispersant has no diffraction peak and is completely amorphous. This is because the dispersant is h...

Embodiment 2

[0029] (1) Add 1g of polycarboxylate superplasticizer to 10mL of water, stir magnetically for 1-2min, add 5g of N-β-aminoethyl-γ-aminopropyltriethoxysilane, stir magnetically for 2-3min until uniform dispersion ;

[0030] (2) Add 0.1 g of graphene into the prepared dispersion, stir magnetically for 2-3 minutes, and disperse ultrasonically for 10 hours to obtain a highly dispersible and stable graphene aqueous dispersion.

Embodiment 3

[0032] (1) Add 0.25g of polycarboxylate superplasticizer to 40mL of water, stir magnetically for 1-2min, add 1.25g of γ-diethylenetriaminopropyltrimethylsilane, stir magnetically for 2-3min until uniform dispersion;

[0033] (2) Add 0.1 g of graphene into the prepared dispersion, stir magnetically for 2-3 minutes, and disperse ultrasonically for 2.5 hours to obtain a highly dispersible and stable graphene aqueous dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com