Method for preparing sodium-hydroxide-loaded active clay

A technology of activated clay and sodium hydroxide, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of high cost, long cycle, low efficiency, etc., and achieve high production efficiency, low energy consumption and cost, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

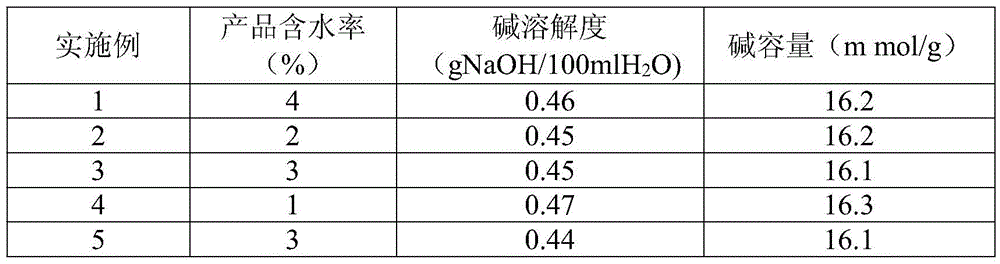

Examples

Embodiment 1

[0024] A preparation method of loaded sodium hydroxide activated clay, comprising the following steps:

[0025] S1: Mix bentonite and activated clay wastewater with a concentration of 12% in a weight ratio of 1.5:8, and stir evenly at a rotating speed of 200r / min to obtain a slurry material A;

[0026] S2: Add the slurry material A prepared in step S1 into hydrochloric acid with a concentration of 15%, the weight ratio of the slurry material A to hydrochloric acid is 2:10, stir at a rotating speed of 500r / min, and heat to 88°C, Maintain the reaction at 88°C for 2 hours to obtain slurry material B;

[0027] S3: press-filter the slurry material B prepared in step S2 at a pressure of 0.92 MPa to obtain a filter cake A with a water content of 42%;

[0028] S4: Add water to the filter cake A prepared in step S3 and stir to dissolve. The amount of water added is 7 times the weight of the filter cake A. After stirring and dissolving the filter cake A is complete, add polyferric sulf...

Embodiment 2

[0033] A preparation method of loaded sodium hydroxide activated clay, comprising the following steps:

[0034] S1: Mix bentonite and activated clay wastewater with a concentration of 8% at a weight ratio of 1.2:4, and stir evenly at a speed of 300 r / min to obtain a slurry material A;

[0035] S2: Add the slurry material A prepared in step S1 into sulfuric acid with a concentration of 13%, the weight ratio of the slurry material A to sulfuric acid is 1:3, stir at a rotating speed of 300r / min, and heat to 85°C, Maintain the reaction at 85°C for 3 hours to obtain slurry material B;

[0036] S3: press-filter the slurry material B prepared in step S2 under a pressure of 0.92 MPa to obtain a filter cake A with a water content of 40%;

[0037] S4: Add water to the filter cake A prepared in step S3 and stir to dissolve. The amount of water added is 6.5 times the weight of the filter cake A. After stirring and dissolving the filter cake A is complete, add polyaluminum sulfate and sti...

Embodiment 3

[0042] A preparation method of loaded sodium hydroxide activated clay, comprising the following steps:

[0043] S1: Mix bentonite and activated clay wastewater with a concentration of 10% in a weight ratio of 1.4:6, and stir evenly at a rotating speed of 250r / min to obtain a slurry material A;

[0044] S2: Add the slurry material A prepared in step S1 into nitric acid with a concentration of 14%, the weight ratio of slurry material A to nitric acid is 1:4, stir at a rotating speed of 400r / min, and heat to 86°C, Maintain the reaction at 86°C for 3 hours to obtain slurry material B;

[0045] S3: press-filter the slurry material B prepared in step S2 at a pressure of 0.93 MPa to obtain a filter cake A with a water content of 42%;

[0046] S4: Add water to the filter cake A prepared in step S3 and stir to dissolve. The amount of water added is 7 times the weight of the filter cake A. After stirring and dissolving the filter cake A is complete, add polyaluminum sulfate and stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com