Method for preparing high-purity potassium tert-butoxide with tert-butanol-water azeotropic solution and potassium hydroxide

A technology of potassium hydroxide and potassium tert-butoxide, applied in the field of preparation of high-purity potassium tert-butoxide, which can solve the problems of high cost, backward technology, dangerous operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

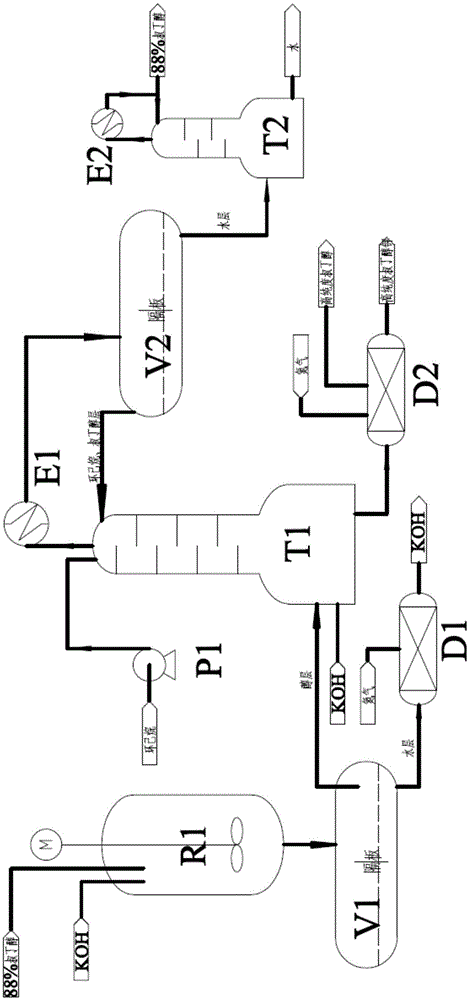

Image

Examples

Embodiment 1

[0034] (1) Weigh 150.3g of 88wt% tert-butanol-water azeotropic solution and 15.3g of potassium hydroxide into the mixing tank R1 for mixing, heat and keep the temperature to 40°C, rotate at 200r / min, stir for 2.5h, and enter the separation tank V1 for a minute Floor.

[0035] (2) 10.9 g of the liquid in the lower layer of the separation tank V1, that is, the water layer, enters the drier D1, evaporates and dries under the protection of nitrogen, and recovers 15.1 g of potassium hydroxide.

[0036] (3) After mixing 139.2g of the upper liquid of the separation tank V1, that is, the alcohol layer and 7.5g of potassium hydroxide, it is placed in the still T1 of the batch rectification column, and cyclohexane is pumped into the top of T1 at a rate of 10g / min, and the timing is started. After 15 minutes, stop cyclohexane feed, a total of 150.2g, control tower top temperature 70 ° C, tower bottom temperature 83 ° C; tert-butanol, water and cyclohexane azeotrope distilled from the top...

Embodiment 2

[0039] (1) Weigh 120.1g of 88wt% tert-butanol-water azeotropic solution and 10.8g of potassium hydroxide into the mixing tank R1 for mixing, heat and keep the temperature to 40°C, the rotation speed is 200r / min, stir for 2.5h, and enter the separation tank V1 for a minute Floor.

[0040] (2) 8.2 g of the liquid in the lower layer of the separation tank V1, that is, the water layer, enters the drier D1, evaporates and dries under the isolation of air (under the protection of nitrogen), and recovers 10.4 g of potassium hydroxide.

[0041] (3) After mixing 112.0 g of the upper liquid of the separation tank V1, that is, the alcohol layer and 6.1 g of potassium hydroxide, it is placed in the still T1 of the batch rectification column, and cyclohexane is pumped into the top of the T1 tower at a rate of 10 g / min, and the timing is started. After 15 minutes, the feeding of cyclohexane was stopped, a total of 149.7g of cyclohexane, and the temperature at the top of the tower was contro...

Embodiment 3

[0044] (1) Weigh 350.7g 88wt% tert-butanol-water azeotropic solution and 31.2g potassium hydroxide into the mixing tank R1 for mixing, heat and keep the temperature to 50°C, rotate at 200r / min, stir for 3h, and enter the separation tank V1 for stratification .

[0045] (2) 22.1 g of the liquid in the lower layer of the separation tank V1, that is, the water layer, enters the drier D1, evaporates and dries under the protection of nitrogen, and recovers 30.8 g of potassium hydroxide.

[0046] (3) After mixing 296.1g of the upper liquid of the separation tank V1, that is, the alcohol layer and 20.2g of potassium hydroxide, it is placed in the still T1 of the batch rectification column, and cyclohexane is pumped into the top of T1 at a rate of 10g / min, and the timing is started. After 40min, stop cyclohexane feeding, 401.6g in total, control tower top temperature 72 ℃, tower still temperature 84 ℃; Tertiary butanol, water and cyclohexane azeotrope distill from tower top, obtain to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com